Poster: F-8K RealShear™ sensor in ARDE Barinco CJ-4E

advertisement

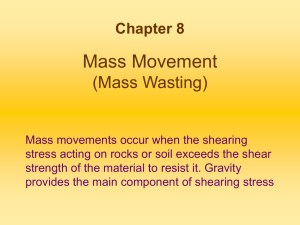

Direct Measurement of Wall Shear Stress in an Arde Barinco Rotor-Stator High-Shear Laboratory Mixer I N N O VATI O N BY ANY M EAS U R E Vadim Stepaniuk, C. Mark Denning, Valery Sheverev - Lenterra, Inc. 105 Lock St., Newark, NJ 07103 www.lenterra.com Roy Scott, Richard Barbini - Arde Barinco, 875 Washington Ave., Carlstadt, NJ 07072 www.arde-barinco.com RealShear Sensors: Principle of Operation Abstract Real-time measurements of wall shear stress at the stator wall in an Arde Barinco highshear mixer were obtained for the first time using a Lenterra RealShear sensor. Glycerol (Newtonian) and shampoo (non-Newtonian) were tested. A model F-8K sensor was used with a +/-8 kPa range. The shear stress as a function of motor RPM was measured for both clockwise and counter-clockwise rotation of the impeller. A measurement rate of 10 kHz enabled resolution of individual passes of each impeller blade which manifested themselves as peaks in the shear stress signal. The sensor was rotated to determine the longitudinal and azimuthal components of the wall shear stress at various RPMs. Data of the type presented here is envisioned to provide a means to verify the shear rate of new and existing mixer designs and also as a means to monitor the viscosity or flow rate of process fluids in real-time. Shear Stress Shear stress is a force that acts on an object in a direction that is parallel to its surface. The amount of shear stress is determined by the viscosity of the fluid flowing across it and how much the fluid velocity varies with varying distance from the wall (known as the “velocity gradient” or “shear rate”). If the shear rate is known, the wall shear stress measured by a RealShear sensor can be used to measure viscosity. In high-shear mixers the shear rate can be calculated using the known geometry of the rotor-stator and the rotation rate of the rotor. A floating element that is in direct contact with the fluid under test, is attached to a cantilever beam which deflects in response to shear stress applied to the floating element surface, and transmits a force to a micro-optical resonator. This resonator has an optical spectrum with peaks centered at particular light wavelengths. When the cantilever deflects, the micro-optical resonator attached to the cantilever experiences strain, causing a shift in its resonant optical wavelength measured with an optical controller. This shift is proportional to the shear stress and viscosity of the fluid. Photograph of the mixing head of an Arde Barinco CJ-4E Reversible Homogenizing Laboratory Mixer with the Lenterra RealShear shear stress sensor attached to the cylindrical stator element. The inset shows the mixing head with the stator removed, revealing the position of the impeller blades. The sensor is mounted into a finely threaded ¼”-80 custom mounting hole, so that the face of the sensor is flush with the inner wall of the cylindrical stator. Applications Figure: High-shear mixer dynamics. Fluid and rotor velocities are shown as well as the wall shear stress induced on the mixer components by the fluid •Scale up of mixing processes from the laboratory to the factory floor •Continuous monitoring of mixing operations to prevent under/overprocessing •Flow rate and viscosity monitoring of flowing or mixing fluids •Characterization of multiphase flows Left: Lenterra RealShear sensor and 2-channel controller. Right: Arde Barinco mixer and control box Wall Shear Stress vs. Time Below are figures showing the wall shear stress signal vs. time for glycerol with the sensor directed horizontally and in the same direction as the impeller motion. The mixer is turned on, allowed to reach steady state operation at 1020 RPM, and then turned off. Wall Shear Stress vs. RPM Time-averaged steady-state wall shear stress as a function of mixer RPM for glycerol and shampoo. Positive values of RPM indicate upward flow (clockwise rotation) while negative values indicate downward flow (counter-clockwise rotation). The apparent viscosity of shampoo was calculated using the known viscosity of Glycerol (1000 mPa-s for room temperature) to determine the coefficient A relating wall shear stress and RPM to viscosity for this particular sensor position and mixer geometry, and applying it to shampoo under the assumption that shear rate and flow conditions are similar. The relation is: μ = A τ / RPM where μ is the viscosity and τ is the measured shear stress. Full view of wall shear stress signal as mixer is turned on and off. Zoom in of the shear stress signal for steady state operation. The peaks in the signal represent moments when an impeller blade passes by the sensor face. Glycerol Shampoo Wall Shear Stress vs. Sensor Angle Close-up of the shear stress as the mixer is turned on. The increasing frequency of the impeller rotation can be seen. Close-up of the shear stress as the mixer is turned off. The wall shear stress was measured for various angles of the sensor’s axis of sensitivity with the horizontal. The sensor was rotated from 0 degrees (pointing in the direction of impeller motion) to 180 degrees (pointing against the impeller motion) . Measurements were made for both upward flow (clockwise rotation) and downward flow (counterclockwise rotation). Counter-intuitively, when the sensor is oriented vertically (90 degrees), the wall shear stress vector points downward for the upward flow configuration of the mixer and vice versa. This unexpected result illustrates that variation of local conditions within the mixing head can be complex.