Microbial polysaccharides Xanthan Gum

advertisement

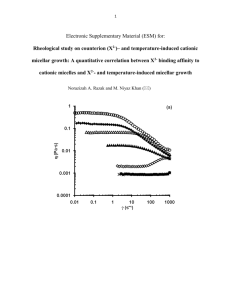

Microbial polysaccharides Xanthan Gum • A polysaccharide • Used as food additive & rheology modifier. • Production involves fermentation of glucose or sucrose by the bacterium, Xanthomonas campestris STRUCTURE • M.W. varies from ~ 1 million - 50 million depending upon preparation • Backbone: – 2 β-D-glucose units linked through the 1 and 4 positions. • Side chain: – 2 mannose units & 1 glucuronic acid unit – Linked to alternate glucose of the backbone at the 3 position. • In all, thus, the chain has repeating modules of five sugar units. • 40-50% of terminal mannose units have a pyruvic acid group linked as a ketal to its 4 & 6 positions. • The other mannose unit has an acetyl group at the 6 position. • 2 of these chains aligns to form a double helix – A rigid rod configuration – High efficiency as a viscosifier of water Structure of Xanthan Preparation • Inoculating a sterile aqueous solution of carbohydrate(s), a N2 source, dipotassium monohydrogen phosphate & some trace elements • Medium is well-aerated & stirred • Xanthan is produced extracellularly in the medium • Final concentration of xanthan: 3-5% by weight • Fermentation for ~ 4 days • Precipitation of Xanthan from the medium by addition of isopropyl alcohol • Dried and milled to give a powder that is readily soluble in water or brine. Applications • Even 1% can greatly increase in the viscosity of a liquid – In foods, used at 0.05 – 0.5%. • Viscosity decreases with high shear rates (mixing, shaking, chewing): Pseudoplasticity – In salad dressings & sauces – Thicker at rest in the bottle to keep the mixture homogeneous – Shear forces due to shaking thins it, so, easily poured – After exiting the bottle, no shear force. So, thickens back & clings to salad. – Stable under a wide range of temperatures and pH • Helps to stabilize the colloidal oil and solid components against creaming. • In frozen foods and beverages, creates the pleasant texture • In toothpaste, serves as a binder to keep the product uniform • In gluten-free baking, to give the dough / batter a "stickiness" – Gluten in wheat to be omitted • For thickening liquids for those with swallowing disorders, since it does not change the color or flavor of foods or beverages. • In the oil industry, to thicken drilling fluids – Fluids serve to carry the solids cut by horizontal drilling bit back to the surface – Also been added to concrete poured underwater, in order to increase its viscosity and prevent washout. • In cosmetics, to prepare water gels usually in conjunction with bentonite clays. • In oil-in-water emulsions to help stabilise the oil droplets against coelesence • Has some skin hydrating properties.