Properties of Wood - Quimby

Properties of Wood

CE A433 – Spring 2008

T. Bart Quimby, P.E., Ph.D.

University of Alaska Anchorage

Civil Engineering

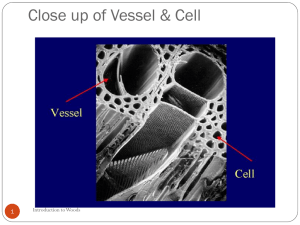

Cellular Makeup

• Cells are elongated, tube like cells

• Cell walls are made of cellulose

• Cells are bound together by lignin http://concise.britannica.com/ebc/art-66141/Cross-section-of-a-tree-trunk

Effect of Cell Structure

• Since the cells are elongated, the wood has different strength properties when stress is transverse or parallel to the cell longitudinal axis.

• Shrinkage properties are also different in each direction.

• Grain runs along the trunk.

• Grain size is non uniform

Grain

Principle Directions

• “With the Grain” =

Longitudinal

• “Cross Grain” or

“Perpendicular to

Grain” = Radial or

Tangential

• Strength and

Shrinkage

Properties are

DIFFERENT IN

EACH DIRECTION

Tangential

Longitudinal

Radial http://concise.britannica.com/ebc/art-66141/Cross-section-of-a-tree-trunk

Moisture Content & Shrinkage

MC = (moist wt – oven dry wt)/ (oven dry weight) x 100

• Living trees may have MC up to 200%.

• Lumber in service has MC less than 20%

• The loss of moisture results in wood shrinkage

– Shrinkage is most pronounced perpendicular to grain

• Moisture is found within the wood cell cavities

(free water) and the cell walls (bound water)

More Moisture

• Fiber Saturation Point (FSP) :

The MC where all the free water is lost, leaving only the bound water.

There is no shrinkage when the

MC is above the FSP

• Volume changes take place as the

MC varies below the FSP.

• Typically, MC continues to decrease after both manufacturing and installation.

• Equilibrium Moisture Content

(EMC) : The in service moisture content

– This can vary with occupancy and/or season

MC vs. Shrinkage

200

180

160

140

120

100

80

60

40

20

0

0

Manufacture

Installation

0.5

Shrinkage

1

Shrinkage Example

• 5 Story Condo in Juneau, AK

• It rained all but

3 days during the 4-5 weeks of framing.

• In the first year after construction there was considerable shrinkage

Imperfections in Wood

Knots http://www.vermonttimberworks.com/images/shake.jpg

Members

Cut from a Log

• Perpendicular to grain direction may be either tangential, radial, or a combination of each

Cross Grain

Cross Grain

Cross Grain http://web.utk.edu/~grissino/images/zuni%20doug-fir.jpg

Sawn Lumber Visual Grading

• Rules agencies establish grading rules based on observed wood quality

• Inspector’s visually grade and mark each piece as it is manufactured

Pressure Treated Wood

• Wood is often chemically treated to increase it’s durability

– Minimizes decay and mold

– Discourages insect infestation

– Fire treatments also available

• Moist, dark (or nearly dark) locations with minimal air circulation are prime locations for decay and mold

• High moisture conditions that are variable are also problematic

Standard Sizes for

Sawn Lumber

• NDS Supplement Section 3, Table 1B

• Nominal Sizes are larger than the actual sizes!

– Check out the sizes! Not all are readily available

– Some available sizes:

• 2x2 to 2x12

• 4x4 to 4x12

• 6x6 to 6x12

Sawn Lumber Size

Classifications

• See text pg 4.30

• Structural Joists and Plank (SJ&P)

– 2 to 4 inches thick

– 2 inches and wider

• Beams & Stringers (B&S)

– 5 inches & thicker

– Width > thickness + 2 inches

• Posts & Timbers (P&T)

– 5 inches & thicker

– Width <= thickness + 2 inches

Glue Laminated Timbers

• Laminations can be strategically used to make efficient use of the best materials.

• Members can be fabricated for particular uses

• Larger, Longer, &

Curved sections are possible http://www.lamisellbeams.com/images/cover-image/lamisell-image03c-shadow04.jpg

Glulams Designed as Beams

• Best material on outer faces

• Butt splice in compression zone

• Scarf splice in tension region

Glulams Designed as Columns

• Materials more uniform

• Butt joints can be used throughout

Glulam Standard Sizes

• See NDS Supplement

Table 1C

• Common Widths for

Western Species GL

– 3.1/8”, 5.1/8”, 6.3/4”,

8.3/4”, 10.3/4”

• Common depths:

– 6” and larger, in 1.1/2” increments http://www.woodnet.org.uk/wec/images/gluelam2.jpg

The National Design Specification

• The “model code” for timber design in the

US

• The NDS Specification tells us what we can do with timber

• The NDS Supplement provides material data for the various types of timber

Basic Design Inequality

• As with all structural codes:

Req’d Strength < Available Capacity

• In the NDS this takes the general form: f < F’ or U < f

N

– Where:

• f = stress caused by internal forces

• F’ = adjusted design stress = F * modifiers

• F = Reference design stresses

• U = the LRFD factored internal force

• N = nominal capacity = F’ * (Section Property)

Sawn Lumber

Reference Values

• NDS Supplement Table 4A

Sawn Lumber

Reference Values

• NDS Supplement Table 4D

Glulam Reference Values

• NDS Supplement Table 5A

Glulam Reference Values

• NDS Supplement Table 5B

Sawn Lumber Design Values

• NDS

Table

4.3.1

• NDS

Table

5.3.1

Glulam Design Values

The Modifiers

C

M

: Wet Service Factor

• Applies to all reference values

• Applies to both Sawn Lumber and Glulams

• Specified in EACH NDS Supplement

Reference Value Table

• This factor generally reduces strengths for wood that is used in a high moisture environment (EMC > 19%)

C t

: Temperature Factor

• Applies to all reference values

• Use for timber used in environments with sustained temperatures up to 150 deg F

• NDS 4.3.4 for Sawn Lumber & NDS 5.3.4 for Glulams

– References NDS Table 2.2.3

C

L

: Beam Stability Factor

• Applies only to bending stress, F b

• Applies to both Sawn Lumber and Glulams

• Found in NDS 3.3.3

– This factor accounts for instability in laterally unsupported beams (i.e. lateral torsional buckling)

• Glulams: This factor is

NOT simultaneously applied with the Volume

Factor, C

V

• More on this factor when we cover beam design

More C

L

• See NDS Equation 3.3-6

• LTB is a function of both the laterally unbraced (buckling) length AND the variation in the moment diagram.

• First check the slenderness ratio

– R

B must not exceed 50

• Then compute C

L

• Note that C

L is a function of the beam size!

– This means that you must know the beam size before computing this factor

– When designing, this may lead to iterative computations

C

F

: Size Factor

• Applies to Sawn Lumber F b

, F t

, and F c bent about the strong axis

• Found in NDS 4.3.6

– 4.3.6.1: For SJ&P see NDS Supplement

Tables 4A and 4B

– 4.3.6.2: For B&S with d > 12”, C

F

(12/d) 1/9

=

– 4.3.6.3: For beams of circular cross section

• The reference values are normalized to a 12” deep member. This factor accounts for the difference.

C fu

: Flat Use Factor

• Applies only to F b for both Sawn Lumber and Glulams when the member is bent about it’s minor axis.

• Found in NDS 4.3.7 and 5.3.7

• For Sawn Lumber, values for C fu are found in the NDS

Supplement Tables 4A, 4B, 4C, and 4F

• For Glulams, values for C fu are found in the NDS

Supplement Tables 5A,

5B, 5C, and 5D

C i

: Incising Factor

• Applies to all reference values for Sawn

Lumber.

• Found in NDS 4.3.8

• Accounts for damage to member due to incisions made for chemical pressure treatment.

C r

: Repetitive Use Factor

• Applies to Sawn

Lumber F b

• Found in NDS 4.3.9

• Read criteria in NDS

• Intended to account for the community effort of a repetitive series of bending members such as joists, rafters, studs, etc.

C p

: Column Stability Factor

• Applies to F c and Glulams for both Sawn Lumber

• Found in NDS 3.7 via 4.3.10 and

5.3.9

• This factor accounts for column stability as a function of slenderness.

• There will be more on this factor when column design is discussed.

C

T

: Buckling Stiffness Factor

• Applies to E min impact on C p for Sawn Lumber, which has an

• Found in NDS 4.4.2 via 4.3.11

• Only applies to truss top chord members, subject to combined bending and axial compression, and made of 2x4 or smaller sections that meet certain criteria.

C b

: Bearing Area Factor

• Applies to F cp for both

Sawn Lumber and

Glulams

• Found in NDS 3.10.4 via

4.3.12 and 5.3.10

• Accounts for increased strength of bearing areas which are, in part, aided by adjacent wood.

• More on this one when we cover beams.

C

D

: Load Duration Factor

• ASD ONLY!!!!

• Applies to F b

, F t

, F v

, F c for both Sawn Lumber and Glulams. Also applies to F rt for Glulams.

• Found in NDS 2.3.2 via 4.3.2 and 5.3.2

• The value of C

D is based on the actual shortest duration load in the load combination being considered. This has the unfortunate affect of making it very difficult to determine the controlling load combination!

Time Effects on

Timber Strength

• “Wood has the property of carrying substantially greater maximum loads for short durations than for long durations of loading.” NDS

2.3.2.1

Determining Controlling

Load Case

• Consider ASD tensile limit state:

T a

/A = f t

< F’ t

= F t

C

D

C

M

C t for ALL LOAD COMBINATIONS

• C

D is different for every considered ASCE 7 load combination

– This makes it tough to see which T a to use.

– To determine the controlling load case divide both sides by C

D

(T a

/C

D

)/A = f t

/ C

D

< F’ t

/ C

D

= F t

C

M

C t

– The load combination that gives the largest T a

/C

D controlling load combination is the

Example

• Consider a column subjected to the loads shown

Structural Elements with

Multiple Load Sources

• Each source has a different make up

• Which ASD LC controls the design of the member?

D, L r

, S, L

D, L

W, E

- Determine C

D for each source and each combination.

- Pick the controlling C

D for the combination and apply to all loads in the combination.

f

: Resistance Factor

• LRFD Only!!!!!

• Applies to all reference values except for E

• Found in NDS Appendix N.3.2 via 4.3.15 and 5.3.13

K

F

: Format Conversion Factor

• LRFD Only!!!!!

• Applies to all reference values except E

• Found in NDS Appendix N.3.1 via 4.3.14 and 5.3.12

• Need to know f to determine K

F

K

F

Table

l

: Time Effect Factor

• LRFD Only!!!!!

• Applies to all reference values except E and E min

.

• Found in NDS Appendix N.3.3 via 4.3.16 and 5.3.14

• This is the LRFD equivalent to C

D

. l accounts for time effects on strength.

• l is easier to apply than C

D since it’s value is specified by ASCE 7 LRFD load combination instead of by actual shortest duration load

• Still need to divide load by l to find controlling cases

The l

Table

• Consider a column with the loads shown

Example

Computing Adjusted Values for a Member

• Once the modifiers have been determined, then you can compute the modified stresses for a member.

• Member design often requires more than one strength limit state, so you will have to compute adjusted values for several types of stress.

LRFD Sawn Lumber Example

ASD Sawn Lumber Example