Woven Fabric Calculation

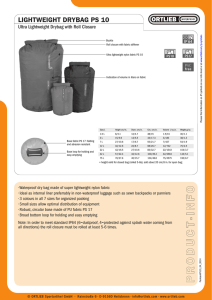

advertisement

Woven Fabric

Calculations

Dr. Jimmy Lam

Institute of Textiles & Clothing

Agenda

Calculations on weft consumption

Calculations on warp preparation

Calculations on warp/weft crimp percentage

Calculations on fabric weight (g/m2)

Weft consumption of a loom

Question

A loom runs at 210 picks/min at an overall

efficiency 82%. The warp width in the reed is

1.2m and the linear density of the weft is 30 tex.

What is the weft consumption per 8 hours

Answer

Weft consumption

A) Length of weft used per hour at 100% efficiency

=1.2 X 210 X 60 /1000km =15.12km per hour

B) At 82% efficiency, the length used in 8 hours

=15.12 X 0.82 X 8 =99.19km

C) Weft consumption, for 30 tex yarn is:

=30 X 99.19 /1000kg =29.76 kg per 8 hours

Warp Preparation

Question

An order for 220 pieces of woven fabric, each

110m in length and 1.2m in wide, is received. In

the finished fabric, the warp crimp is 9% and

there are 38 ends/cm. The creel of the direct

warping process has a maximum capacity of

500 cones.

– A) How many back beams are required

– B) What length of warp is on each?

Warp Preparation

Answer

A) Total number of ends:

– Ends/cm x finished width in cm

– =38 x 120 =4560 ends

– Since the creel can hold 500 cones, the number of ends per

back beam could be 456, and 10 back beams should be used

B) The total length of warp is given by

– Number of pieces X piece length X (100+crimp)/100

– =220X110X109/100 =26,378m

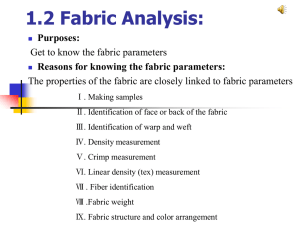

Crimp Percentage of Woven Fabric

The crimp percentage is the difference between

straightened thread length and the distance between

the ends of the thread in the fabric.

Crimp % = (l-s)/s x 100

Measuring crimp practically is not always a simple

procedure. The length of the crimped yarn may be

easily measured, but to decide when the crimped

yarn removed no longer retains crimp is not easy.

Example

Crimp %

Crimp % , (Formula 1)

C=(L-S)/S * 100%

– Where L is warp length, S is cloth length

Warp Length (L), (Formula 2)

L=(1+C)* S

– Where C is crimp %, S is cloth length

Cloth length (S), (Formula 3)

S=L/(1+C)

– Where L is warp length, C is crimp %

Question 1

Crimp %

A cotton cloth is analysed, and from a tested

strip of 20cm, the mean warp length is 21.2cm.

Determine both the crimp and take-up

percentage.

Answer

Crimp Percentage:

(21.2 – 20.0) / 20 = 6.0%

Take up Percentage

(21.2-20.0)/21.2 = 5.66%

N.B In many fabrics, there is not too great difference between the

warp and weft crimps, but there are examples of quite large

differences. E.g. in cotton poplin, the warp cirmp could be 14%

and the weft crimp in only 2%

Example 2

Crimp %

Ex2:

Calculate the length of warp required to weave

160m of cloth if the warp crimp is 12%

Ex3

What length of cloth can be woven from 800m

of warp if the warp crimp is 8%

Answer

Ex2

S= cloth length = 160m

Crimp = c = 0.12 and therefore warp length will

be:

C= (l-s)/s X100%; and c =l/s -1 and l=(1+c)*s

L=(1+0.12)*160 = 179.2m

Answer

Ex3

Warp Length, L =800m , find cloth length, s

S=L/(1+c) = 800/(1.08)

=740.8m

Fabric Weight Calculations

(Areal Density)

In the imperial system, fabric weight is expressed in

ounces per square yard.

In SI, the mass per unit area is grams per square meter.

If we get a 10 cm x 10 cm fabric, the fabric is easy to

measure and multiplied by 100 to give fabric weight

(g/m2).

However, if we don’t have the fabric, the fabric weight

can be calculated by fabric density (sett), yarn count

and crimp percentage.

Fabric Weight

Calculation

Question 1:

A cotton fabric is woven from 18 tex warp and

21 tex weft. The fabric has 28 ends/cm and 25

picks/cm, and the warp and weft crimp

percentages are 2.5 and 9.0 respectively.

Estimate the areal density (fabric weight g/m2)

Answer

Mass of warp per square meter

– =(ends/m)/1000 x (100+crimp%)/100 x tex

– =(28 x 100)/1000 x (102.5 *18)/100

– =51.5 g

Note factor 1000 is introduced because tex is defined in

terms of g/km

Mass of weft per square meter

– =(picks/m)/1000 x (100+crimp%)/100 x tex

– = (25*100)/1000 x (109*21)/100

– =57.2g

Fabric weight =51.5 + 57.2 =108.8 g/m2

If we use ends/cm in the formula, we could omit

the factor of 100 on the bottom line, the total

mass per square meter will be written:

{(ends/cm x 100+crimp% x tex) + (picks/cm x

100+crimp x tex)} /1000

={(28*102.5*18) +(25*109*21)}/1000

=51.6+57.2 =108.8g/m2

Fabric Weight

Calculation

Question 2

A satin strip cotton fabric is woven from a warp of 25

tex in the plain sections and from one of 12 tex in the

satin weave. There are 40 repeats of the pattern in a

fabric width of 1.28m, each repeat being made up of 48

ends of plain weave and 72 ends of satin weave.

The crimp is 8% in the plain weave and 5% in the satin

weave. The weft is 14 tex, with 28 picks/cm and has 6%

crimp.

Calculate the aerial density of this fabric (g/m2)

Answer

For this patterned fabric in which varied yarns are used,

each type of yarn will require separate treatment.

Number of pattern repeats per meter width= 40x1/1.28

=31.25

Fabric Weight (Warp Yarn)

Hence, number of plain weave ends/m =31.25 x 48; and

Mass of plain weave ends/m

(31.25*48)/1000 *(108*25)/100 =40.5g

Similarly, mass of satin weave ends/m

(31.25*72)/1000 * (105*12)/100=28.4 g

Fabric Weight (Weft yarn)

Mass of weft per meter

=28*106*14*100/1000 =41.6 g

Fabric weight (warp +weft) per square meter

=40.5+28.4+41.6=110.5 g/m2

Fabric Weight

(Imperial System)

Sometimes, we need to express fabric weight in

Imperial System (oz/yd2), the calculation is as

follows:

Question 3

Calculate the fabric weight (oz/yd2) for the

following cotton cloth:

22s x18s, 64 x 60 and 6.5% x 8.5%

Convert the system to SI

Tex = 590.5/cotton count

Warp =590.5/22 =26.8 tex

Weft=590.5/18=32.8 tex

Sett /cm =Ends per inch /2.54

Ends/cm =64/2.54=25.2

Picks/cm =60/2.54 =23.6

Fabric Weigth (g/m2)

{(25.2*106.5*26.8)+(23.6*108.5*32.8)}/1000

=155.g/m2

Since 1 g/m2 =0.029 oz/yd2

Fabric Weight (oz/yd2) = 155*0.029

=4.52 oz/yd2

Fabric Weight

Denier

Question 4

Calculate the weight of the fabric (oz/lb2) for

the following nylon fabrics:

45 denier x 45 denier; 104 x 96 and 4% x 5%

Convert it to SI

Tex = Denier /9

– Warp tex =45/9 =5

– Weft tex =45/9=5

Ends/cm =ends per inch /2.54

– Ends/cm= 104/2.54=40.9

– Picks/cm =96/2.54=37.7

Fabric Weight (g/m2)

{(40.9 x 104 x 5) + (37.7 x 105 x 5)}/1000

41 g/m2

Since g/m2 =0.029 oz/lb2

Fabric Weight (oz/lb2) = 41 x 0.029

=1.19 oz/lb2