Design and Development of the FSM

advertisement

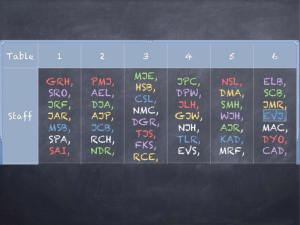

Design and Development of the FSM (Fast steering Secondary Mirror) Myung Cho, NOAO-GSMTPO Kwijong Park, KASI Young-Soo Kim, KASI October 4, 2010 GMT2010: Design and Development of FSM 1 OUTLINE 1. 2. 3. 4. Prior Work: Magellan Secondary Mirror modeling FSM Configuration Design and Development (work in progress) GMT FSM Performance Predictions a. Gravity Analysis b. Thermal Analysis c. Natural Frequency analysis d. Lateral support flexure analysis e. Sensitivity analysis f. Zenith Angle effects 5. Summary and Conclusion 6. Next Steps October 4, 2010 GMT2010: Design and Development of FSM 2 Magellan Heritage Magellan heritage: Magellan secondary mirror GMT Primary: 25.4m (8.4m x 7) Secondary: 3.2m (1.06m x 7) Shape: Ellipsoid Focal ratio: F/0.7 Final focal ratio: F/8 Magellan telescope Primary: 6.5m Secondary: 1.3m Shape: Paraboloid Focal ratio: F/1.25 Final focal ratio: F/11.0 ※ Gregorian 6.5m Magellan telescope October 4, 2010 25.4m GMT GMT2010: Design and Development of FSM 3 Magellan M2 Assembly Secondary Mirror Assembly of Magellan telescope For GMT FSM design and development, take a conservative engineering approach; utilize concepts established from the F/11 M2 of Magellan telescope. October 4, 2010 GMT2010: Design and Development of FSM 4 GMT and GMT FSM Primary: 25.4m (8.4m x 7) Secondary: 3.2m (1.06m x 7) Shape: Ellipsoid Focal ratio: F/0.7 Final focal ratio: F/8 Gregorian October 4, 2010 GMT F/8 Gregorian beams Conjugated M1 and M2 GMT2010: Design and Development of FSM 5 FSM assembly layout October 4, 2010 GMT2010: Design and Development of FSM 6 FSM optical prescription FSM optical prescription (as of 9/2010): FSM M2 nominal segment Configuration: October 4, 2010 GMT2010: Design and Development of FSM 7 175mm 140mm 1060mm FSM Error Budget specification Error budget: Encircled Energy diameters at 80% (EE80) Orientation Zenith Horizon Figure error October 4, 2010 80% EE Specifications 0.020” (arc-seconds) 0.030” 0.039” GMT2010: Design and Development of FSM 8 Assumptions in FE • Finite Element mirror model • 3D solid elements • Center mirror of the FSM array (on-axis) • Clear aperture in the optical surface evaluations: OD=1060mm • Solid Zerodur concave lightweight (63%) • • • • • Nominal mirror thickness: 140mm RADCV=4.2m; sag=0.031m Center of gravity (CG) = 0.0205m (from vertex) Mass=105 kg; Ixx=6.3 kg-m2, Izz=12.3 kg-m2 at CG CTE = 20 E-9 /’C Y X • Support systems • Axial support = 3 point mount with vacuum • Lateral support = single central flexure FSM local coordinates October 4, 2010 GMT2010: Design and Development of FSM 9 FSM Support system • Three axial support (defining points) mounted at the mirror back surface • Axial supports oriented parallel to the optical axis (vertical, Z-axis) • Axial gravity is fully compensated by a vacuum system at Zenith • Lateral gravity is held by a flexure at the mirror center position on the M2 CG plane. FSM support system October 4, 2010 GMT2010: Design and Development of FSM 10 Support system – FE modeling Axial support: Vacuum floating system W: Weight Atmospheric pressure was applied on the entire front surface of the FSM from the vacuum Magnitude of the atmospheric pressure is equivalent to the axial gravity of FSM P: Atmosphere pressure (counter-pressure) Reaction force at the three axial supports is to be zero; therefore, the FSM is floating This floating axial system provides a low surface error in Zenith. Lateral support: Flexure system FSM gravity is held by a flexure at the mirror center location Line of action is on the mirror CG plane No axial force is to be induced at Horizon October 4, 2010 GMT2010: Design and Development of FSM 11 Mirror Blank Optimization Four different configurations (depth effect): 1. Gravity print-through 2. Natural Frequency A. 100mm : 78.8kg Baseline: favorable configuration for stiffness and stress requirements B. 120mm : 84.1kg Depth=140mm Face sheet thickness=20mm Mass=105kg C. 140mm : 89.3kg D. 150mm : 91.9kg E. 150mm (rib = 10mm) : 118.4kg October 4, 2010 GMT2010: Design and Development of FSM 12 FSM: Gravity Print-through Lateral Gravity (Gy) Axial Gravity (Gz+vacuum) RAW (un-corrected)) P.T.T corrected PTT: RMS=6.1 nm surface PTT: RMS=3.8 nm surface Optical Surface deformation maps October 4, 2010 GMT2010: Design and Development of FSM 13 FSM: thermal gradient, T(z) Thermal gradients delta T =1oC/0.1m along Z axis (Optical axis) (CTE = 20 x 10-9 /oC) P.T.T corrected Displacement in Z: Max.= 18 nm; PV=35 nm PV=22nm; RMS=6.3nm surface Mechanical and Optical surface deformations October 4, 2010 GMT2010: Design and Development of FSM 14 Natural Frequency (first mode) 1st Mode Shape: Astigmatism at 720 Hz 1st natural frequency mode with free-free condition Mirror mass = 105 Kg in the FE model October 4, 2010 GMT2010: Design and Development of FSM 15 Natural mirror mode (low order modes) 1 3 4 6 8 10 12 14 16 17 October 4, 2010 19 GMT2010: Design and Development of FSM 21 16 Typical Lateral Flexures in trade Thickness of Disk Flexure 5mm 0.7mm 8.68mm 15mm 10.16mm 100mm Sample: Section Plane of Lateral Flexure October 4, 2010 GMT2010: Design and Development of FSM 17 Lateral Flexure Trade study Stress analysis of lateral flexure was performed initially based on thickness and materials provided by GMTO. Further assumptions were made for parametric study. This work is in progress. Typical results during trade study in static, buckling and non-linear analysis y x Stress calculation October 4, 2010 Lateral deformation GMT2010: Design and Development of FSM Buckling analysis 18 Sensitivity: Axial gravity/vacuum Gravity Axial gravity compensated by pressure Atmosphere pressure 97% compensation Fully Balanced 3% residual by axial support 10N each RMS=4.1nm surface RMS=3.8nm surface 3% residual force by lateral support (work in progress) Optical Surface deformation maps October 4, 2010 GMT2010: Design and Development of FSM 19 Sensitivity: vacuum seal Seal force applied along the edge of front surface (Flange) (currently assumed a uniform distribution) 10 N/m along optical axis RMS=12.2nm surface 10 N/m along radial direction RMS=1.0nm surface Focus corrected October 4, 2010 RMS=3.9nm RMS=0.4nm GMT2010: Design and Development of FSM 20 Zenith Angle Dependence Gravity Print-through effects from Zenith angle variations • Print-through from Zenith variation • Combination of optical surfaces from Axial and Lateral cases • Axial support print-through • RMS surface 3.8 nm • Lateral support print-through • RMS surface 6.1 nm • RMS calculations based on surface polished out at FSM face-up October 4, 2010 GMT2010: Design and Development of FSM 21 Optical calculations (AXIAL) Surface error Slope Y AXIAL RMS surface error RMS surface X_slope RMS surface Y_slope EE80 diameter 3.8 0.035 0.035 0.007 Slope X nm micro_rad micro_rad arcsec EE80 diameter October 4, 2010 GMT2010: Design and Development of FSM 22 Optical calculations (LATERAL) Surface error Slope Y LATERAL RMS surface error RMS surface X_slope RMS surface Y_slope EE80 diameter October 4, 2010 6.1 0.082 0.139 0.005 Slope X nm micro_rad micro_rad arcsec GMT2010: Design and Development of FSM 23 Optical calculations (ZA=60o) (polished and tested at FSM face-up) Surface error Slope Y Zenith Angle at 60 RMS surface error RMS surface X_slope RMS surface Y_slope EE80 diameter October 4, 2010 5.6 0.073 0.121 0.005 Slope X nm micro_rad micro_rad arcsec GMT2010: Design and Development of FSM 24 Structure Function calculations (ZA=60o) Structure function of random variable, P(r) D() = < | P(r+ ) - P(r) |2 > Phase map Structure function at ZA=60o: sqrt(D) in WFE RMS WFE: 11.2 nm October 4, 2010 GMT2010: Design and Development of FSM 25 Summary and Conclusion FSM mirror blank optimum configuration: D=1.06m; depth=140mm; face plate thickness=20mm; mass=105kg Lightweight glass or glass ceramic mirror FSM support system provides adequate optical performances: Gravity print-through effects: – met error budget Axial gravity: 3.8nm RMS surface; EE80 = 0.007 arcsec (< 0.020) Lateral gravity: 6.1nm RMS surface; EE80 = 0.005 arcsec (< 0.020) FSM thermal effects were accessed: Thermal soak, thermal gradients Natural frequency analysis for FSM mirror blank: Lowest mode is at 720 hz (astigmatic mode) – stiff mirror Optical performances at various Zenith angles: – met error budget Assume: FSM figured and tested at its face up position At ZA=60 degrees: EE80 = 0.005 arcsec (< 0.039) October 4, 2010 GMT2010: Design and Development of FSM 26 Next Step FSM performance evaluations Support sensitivity Vacuum seals and seal force sensitivity FSM mirror support system trade study Axial support : Vacuum support Lateral support : Lateral support diaphragm/flexure Stiffness of axial and lateral supports Work with GMTO for Magellan Secondary mirror engineering document: Lateral support flexure and bonding procedure Vacuum October 4, 2010 GMT2010: Design and Development of FSM 27 Acknowledgments The authors gratefully acknowledge the support of the GMT Office, Matt Johns and Stephen Shectman. This work was partially contributed by the scientists and engineers from the KASI and KRISS of Korea. Students of the University of Arizona are also greatly acknowledged. The individual contributors are: Il Kweon Moon, Andrew Corredor, Christoph Dribusch, Ju-Heon Koh, Eun-Kyung Kim. October 4, 2010 GMT2010: Design and Development of FSM 28