Lecture 2-3-2

advertisement

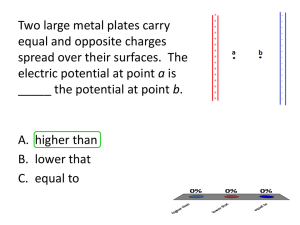

Forestry 485 Lecture 2-3-2: Wood Surface Properties, Part II Surface Properties: Wetting Regardless of adhesion mechanism, optimal adhesion is dependent upon effective contact of adhesive and adherend; contact is dependent upon Surface Wetting phenomenon. Surface Energy: “Bond Breaking” Bonds broken to create surfaces=“excess energy in the surface” or “surface energy” Surface does not exist of itself: It must be part of an interface (two substances or phases) Liquid-vapor, liquid-solid interactions result from dispersion forces and hydrogen bonds Surface Energy vs. Surface Tension Strictly, surface energy DOES NOT equal surface tension HOWEVER, it is generally impractical to measure precise values, especially for solids THUS, the terms “surface energy” and “surface tension” are often taken as synonymous, except in theoretical treatments Surface Energy Magnitude Organic polymer γ surfaces; typical values: < 100 mJm-2 Hard (low energy) inorganic surfaces (metals, ceramics, etc.) γ > 100’s to 1,000’s mJm-2 (high energy) Slide courtesy Dr. Doug Gardner, University of Maine Surface Energy Measurement Sessile Drop Method Capillary Rise Method Wilhelmy Plate Method http://www.ksvinc.com/wilhelmy_plate.htm From: Fundamentals of Adhesion, ed. Lee, L.H., p.126, Plenum Press, New York, 1991 Contact Angle Hysteresis Microscopic “surface inhomogeneities” (roughness) causes variations in contact angle Contact angle measurement varies between advancing and receding liquid-solid interface Dynamic contact angle measurement (e.g., Wilhelmy plate method) helps to account for these variations Contact Angle Hysteresis Another cause of hysteresis is “heterogeneous contamination” of surfaces with low-energy impurities In the case of wood adherends, such “contaminants” are typically hydrophobic extractives Young’s Equation: Proposed in 1805 (!) to explain the equilibrium of a drop of liquid on a solid surface “When a droplet of liquid, L, with its vapor, V, is at rest on a solid surface, S, it takes a configuration which minimizes the energy of the system and highlights the liquid-solid interactions.” The equilibrium condition is represented by: γSV = γSL + γLVcos Ө - Fourche, 1995 Contact Angle Vapor γLV Liquid Ө γSL γSV Solid Young’s Equation: γSV = γSL + γLVcos Ө Or cos Ө = (γSV – γSL)/ γLV If Ө = 0, Spreading Occurs If Ө < 90o, Wetting is Favorable If Ө > 90o, Wetting is not Favorable Critical Surface Energy C = Critical Surface Energy, is that surface energy at which complete wetting occurs Notice (in the following slide) that if cos θ = 1, cos-1 θ = 0o Zisman Plots cos Ө = 1 + b (C - L) Ө = measured Contact Angle b = the slope of the line C = Critical Surface Energy L = Liquid Surface Energy cos theta Zisman Plot 1.1 0.9 0.7 0.5 10 γC = 18 mN/m 20 30 40 Surface Energy (mN/m) 50 Dupre’s Equation: Work of Adhesion (“postulated centuries ago”!!) Consider: “An elastic material of unit crosssection is subjected to a tensile force. The material breaks, creating two new surfaces.” Since “the new surfaces are each made of the same material, then the total energy expended must be twice the surface energy of the material.” Thus, work of COHESION, Wcoh = 2γ » Pocius, 2002, chapter 4 1 2 Dupre’s Equation: Work of Adhesion NOW, Consider: “A situation in which two dissimilar materials are in intimate contact. A tensile force splits the materials into two dissimilar materials. If the sample is of a unit cross sectional area, then the energy expended should be the sum of the two surface energies…” BUT, “because the two dissimilar materials were in contact there were intermolecular forces present that are now missing since the materials were separated. That is, an interfacial energy may have been present before the materials were split apart. As this energy is missing after the two surfaces are separated, we must subtract it from the energy used to create the two new surfaces.” » Pocius, 2002, chapter 4 Work Of Adhesion Thus, we have the Dupre’ Equation: WA = γ1 + γ2 – γ12 Where γ1 =surface energy of material 1, γ2 =surface energy of material 2, and γ12 = interfacial energy between materials 1 and 2. Definition: Work required to separate two bonded materials solely in terms of surface energy. 1 1 2 2 Resin – Wood Furnish Interactions Goal: Achieve even distribution of resin within adhesive joint, and promote intimate contact between resin molecules and furnish surface. Mechanism •Application – Droplet Formation •Fluid Motion – Compression/Consolidation •Molecular Motion – Spreading/Wetting Acknowledgement Illustrations in slides 2, 11, 13-14 and 16 courtesy of Carter Johnson. Literature cited is from module 2 optional readings, except for Pocius, chapter 4 (copy available on request)