Turbine Unit 2 PPTX file

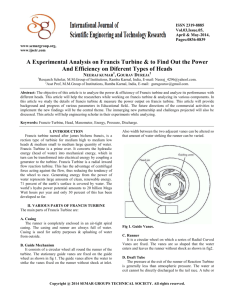

advertisement

Turbines RAKESH V. ADAKANE DEPARTMENT OF MECHANICAL ENGINEERING YCCE NAGPUR HYDRAULIC TURBINES The device which converts hydraulic energy into mechanical energy or vice versa is known as Hydraulic Machines. The hydraulic machines which convert hydraulic energy into mechanical energy are known as Turbines and that convert mechanical energy into hydraulic energy is known as Pumps. Different type of turbine use in hydro power station 1.High head schemes. (Impulse turbine-pelton wheel) ( < 300 m.) 2.Medium head schemes.(reaction turbine ) (60m to 300 m.) 3.Low head schemes. (propeller turbine ) ( > 60m.) IMPULSE TURBINE (PELTON WHEEL) GE Hydro construction of penstock in hydro power station.` Pelton to Francis Pelton to Francis UNIT 02 Reaction Turbines Reaction turbines are those turbines which operate under hydraulic pressure energy and part of kinetic energy. In this case, the water reacts with the vanes as it moves through the vanes and transfers its pressure energy to the vanes so that the vanes move in turn rotating the runner on which they are mounted. Reaction Turbines Types 1. Radially outward flow reaction turbine 2. Radially inward flow reaction turbine The main component parts of a reaction turbine are: • (1) Casing, (2) Guide vanes (3) Runner with vanes (4) Draft tube COMPONENT PARTS OF A REACTION TURBINE • • • • Casing: This is a tube of decreasing cross-sectional area with the axis of the tube being of geometric shape of volute or a spiral. The water first fills the casing and then enters the guide vanes from all sides radially inwards. The decreasing cross-sectional area helps the velocity of the entering water from all sides being kept equal. The geometric shape helps the entering water avoiding or preventing the creation of eddies. Guide vanes Runner with vanes: The runner is mounted on a shaft and the blades are fixed on the runner at equal distances. The vanes are so shaped that the water reacting with them will pass through them thereby passing their pressure energy to make it rotate the runner. Draft tube: This is a divergent tube fixed at the end of the outlet of the turbine and the other end is submerged under the water level in the tail race. The water after working on the turbine, transfers the pressure energy there by losing all its pressure and falling below atmospheric pressure. The draft tube accepts this water at the upper end and increases its pressure as the water flows through the tube and increases more than atmospheric pressure before it reaches the tailrace. The Francis Turbine Francis turbines • It is a reaction turbine developed by an English born American Engineer, Sir J.B. Francis. • The water enters the turbine through the outer periphery of the runner in the radial direction and leaves the runner in the axial direction, and hence it is called ‘mixed flow turbine’. • It is a reaction turbine and therefore only a part of the available head is converted into the velocity head before water enters the runner. • The pressure head goes on decreasing as the water flows over the runner blades. • The static pressure at the runner exit may be less than the atmospheric pressure and as such, water fills all the passages of the runner blades. • The change in pressure while water is gliding over the blades is called ‘reaction pressure’ and is partly responsible for the rotation of the runner. • A Francis turbine is suitable for medium heads (45 to 400 m) and requires a relatively large quantity of water. The Francis Installation View of Draft tube in Hydro electric power plant.` FORMULAE 1. Speed ratio = 2. Flow ratio = u1 2g H V f 1 where H is the Head on turbine where Vf1 is the velocity of flow at inlet 2 g H 3. Discharge flowing through the reaction turbine is given by Q = D1 B1 Vf1 = D2 B2 Vf2 Where D1 and D2 are the diameters of runner at inlet and exit B1 and B2 are the widths of runner at inlet and exit Vf1 and Vf2 are the Velocity of flow at inlet and exit If the thickness (t) of the vane is to be considered, then the area through which flow takes place is given by ( D1 nt) where n is the number of vanes mounted on the runner. Discharge flowing through the reaction turbine is given by Q = ( D1 nt) B1 Vf1 = ( D2 nt) B2 Vf2 4. The Head on the turbine is given by Where p1 is the pressure at inlet. 2 H V2 2g 1 H p1 g V1 2 2 g (V w 1u 1 V w 2 u 2 ) g 5. Work done per second on the runner = a V1 (Vw1u1 Vw2u2) = Q (Vw1u1 Vw2u2) D1 N 6. u1 60 7. u2 D2 N 60 8. Work done per unit weight W ork done per second = W eight of w ater striking per second Q V w 1u 1 V w 2 u 2 = Qg 1 g V w 1u 1 V w 2 u 2 9. If the discharge at the exit is radial, then Vw2 = 0 and hence Work done per unit weight = 1 V u g 10. . Hydraulic efficiency = R .P . W .P . w1 1 Q V w 1u 1 V w 2 u 2 gQH 1 gH V w 1u 1 V w 2 u 2 11. If the discharge at the exit is radial, then Vw2 = 0 and hence Hydraulic efficiency = 1 V u gH w1 1 The Francis Installation Working diagram Hydro electric power plant.` Axial flow (Kaplan) Turbine (Reaction)