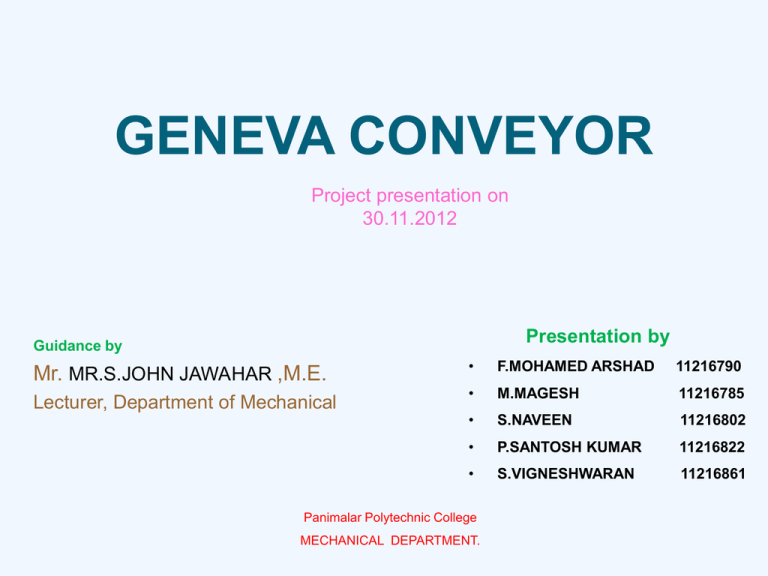

GENEVA CONVEYOR Guidance by

advertisement

GENEVA CONVEYOR Project presentation on 30.11.2012 Presentation by Guidance by Mr. MR.S.JOHN JAWAHAR ,M.E. Lecturer, Department of Mechanical • F.MOHAMED ARSHAD 11216790 • M.MAGESH 11216785 • S.NAVEEN 11216802 • P.SANTOSH KUMAR 11216822 • S.VIGNESHWARAN 11216861 Panimalar Polytechnic College MECHANICAL DEPARTMENT. This is the new innovative concept mainly used for industries. It is simple in construction and the working process is easy. In industries, it is very necessary to move the components from one area to the other in a regular basis. It is necessary to minimize the workers involved in it. We have designed a conveyor with Geneva drive which is useful in industries. So, here we have made a conveyor model which is used for material transformation from one place to another. Main components used in this project are motor, belt, roller, bearing and Geneva wheel. Panimalar Polytechnic College In our project we are using the Geneva conveyor for material handling in industries. It consists of motor, rollers, belt, and geneva mechanism. Two rollers are mounted according to the required distance the belt is mounted on the rollers on which the materials are placed. The rollers shaft is coupled with the geneva drive. The geneva drives shaft is coupled with the motor shaft hence when power is supplied to the motor rollers rotate with a certain time delay according to the geneva drive and the belt moves along the rollers. Thus material handling is carried out. With help of the geneva drive the time delay can be achieved which avoids the use of stepper motor thus reduces the cost involved. Panimalar Polytechnic College BLOCK DIAGRAM FOR GENEVA CONVEYOR DRAWING FOR GENEVA CONVEYOR Panimalar Polytechnic College PART NAME BASE FRAME BELT ROLLER BEARING GENEVA WHEEL SUPPORTING COLOUMN DC-MOTOR PIN Panimalar Polytechnic College It is applicable in the production industries and in automobile industries for mass production. Applicable where time delay is necessary in material handling. ADVANTAGE Low cost. Saves Man Power. Saves time. Time delay can be achieved easily.