Lecture 18: Control Volumes: System Analysis

advertisement

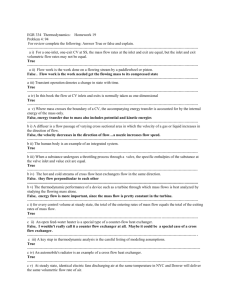

EGR 334 Thermodynamics Chapter 4: Section 10-12 Lecture 18: Integrated Systems and System Analysis Quiz Today? Today’s main concepts: • Be able to explain what an integrated system is • Be able to describe the components of some common integrated systems • Apply mass balance, energy balance, and continuity to streams of flow through integrated systems. Reading Assignment: • No New Reading Assignment for Wed. • Read Chap 5 for Friday. Homework Assignment: Problems from Chap 4: 95, 98, 102 3 Terms for Chap 5 Class Discussion : • • • • • • • • • • • • Spontaneous Heat Transfer Clausius Statement Kelvin-Planck Statement Entropy Statement Irreversible vs. Reversible Internally Reversible Process Carnot Corollaries Carnot Efficiency Max. heat pump efficiency Max. refrigeration cycle COP Carnot Cycle Clausius Inequality You may want to create a summary sheet to help you discuss each of the concepts. System Integration ►Engineers creatively combine components to achieve some overall objective, subject to constraints such as minimum total cost. This engineering activity is called system integration. ►The simple vapor power plant of Fig 4.16 provides an illustration. Sec 4.11: System Integration 5 Integrated Thermodynamics Systems: System Integration : Combine components to make a useful cycle Some common systems: - Power Plant - Refrigerator Components: - Heat Pump Pipes Nozzles/Diffusers Turbines Compressors/Pumps Heat Exchanger Throttling Sec 4.11: System Integration 6 Power Plant Cycle 1. Boil Water Burn something Nuclear Reaction Geothermal 2. Use the steam as it rises to turn a turbine. Sec 4.11: System Integration 7 Power Plant Cycle 3.Condense Steam (to recycle water) using a heat exchanger 4. Pump water back to boiler. Sec 4.11: System Integration 8 Power Plant Cycle 2. Turbine 3. Condenser 4. Pump 1. Boiler Sec 4.11: System Integration 9 Power Plant Cycle QCV 1. Boiler 2. Turbine . m tixe WCV . m ni . WCV 4. Pump QCV 3. Condenser Sec 4.11: System Integration 10 Refrigeration cycle 1.Condenser We know that condensing something will remove heat from the fluid. 3. Evaporator To have something to condense, we must have evaporated something. (Both are heat exchangers) Sec 4.11: System Integration 11 Refrigeration cycle 1. Condenser 4. Compressor 3. Evaporator 2. Throttling valve/ Expander Sec 4.11: System Integration 12 Refrigeration Cycle 1. Condenser QCV WCV 4. Compressor 2. Throttling valve/ Expander 3. Evaporator QCV Sec 4.11: System Integration 13 Example: (4.103) A simple gas turbine power cycle operating at steady state with air as the working substance is shown in the figure. The cycle components include an air compressor mounted on the same shaft as the turbine. The air is heated in the high-pressure heat exchanger before entering the turbine. The air exiting the turbine is cooled in the lowpressure heat exchanger before returning to the compressor. KE and PE effects are negligible. The compressor and turbine are adiabatic. Using the ideal gas model for air, determine the (a) Power required for the compressor, in hp, (b) Power output of the turbine, in hp, (c) Thermal efficiency of the cycle Sec 4.11: System Integration Example: (4.103) state state 14 (a) Power required for the compressor, in hp, (b) Power output of the turbine, in hp, (c) Thermal efficiency of the cycle 11 22 33 44 11 >p11 pp22>p =p22 pp33=p 11 p4=p 520 520 650 650 2000 2000 980 980 AV (ft (ft33/min) /min) 30,000 30,000 AV (atm) pp (atm) (°R) TT (°R) (BTU/lb) hh (BTU/lb) 124.27 155.51 504.71 236.02 From Table A-22E : Ideal Gas Properties of Air state Q W Compressor 0 ? Heat Ex 1 Turbine Heat Ex 2 0 0 ? 0 Assumptions •Steady State •KE= PE = 0 •Turbine and compressor are Adiabatic (QCV= 0) •No work in Heat Ex. (WCV = 0) •Air is modeled as an ideal gas Sec 4.11: System Integration 15 Example: (4.103) (a) Power required for the compressor, in hp, (b) Power output of the turbine, in hp, (c) Thermal efficiency of the cycle state 1 AV (ft3/min) T (°R) p2>p1 p3=p2 1 520 650 2000 980 124.27 155.51 504.71 state Q W Compressor 0 ? Heat Ex 1 0 Turbine 236.02 0 ? Heat Ex 2 0 Ideal Gas Eq. A V 1 and v1 3 m 4 1 Using Continuity Eq. m 3 30,000 p (atm) h (BTU/lb) 2 v R T1 P1 so m A V 1 p1 M R T1 2 (3 0, 0 0 0 ft / m in )(1 4 .7 lb f / in )( 2 8 .9 7 lb m / lb m o l ) 1 4 4 in 2 6 0 m in (1 5 4 5 ft lb f / lb m o l R )(5 2 0 R ) 1 ft 2 1 137, 394 hr lb hr Sec 4.11: System Integration 16 Example: (4.103) (a) Power required for the compressor, in hp, (b) Power output of the turbine, in hp, (c) Thermal efficiency of the cycle state 1 AV (ft3/min) p (atm) T (°R) h (BTU/lb) 2 3 4 30,000 1 p2>p1 p3=p2 1 520 650 2000 980 124.27 155.51 504.71 236.02 state Q W Compressor 0 -1687 ? Heat Ex 1 Turbine 0 0 Heat Ex 2 ? 0 Energy Balance (Compressor): dE CV dt QCV WCV W C V 137 394 2 V mh gz 2 lb m hr 124.27 155.51 BTU lb m W C V m h1 h 2 1 hp 2545 B tu / hr 1687 hp Sec 4.11: System Integration 17 Example: (4.103) (a) Power required for the compressor, in hp, (b) Power output of the turbine, in hp, (c) Thermal efficiency of the cycle state AV (ft3/min) p (atm) T (°R) h (BTU/lb) 1 2 3 4 30,000 1 p2>p1 p3=p2 1 520 650 2000 980 124.27 155.51 504.71 W C V (137 394 lb m hr Q W Compressor 0 -1687 Heat Ex 1 Turbine 236.02 Energy Balance (Same as Compressor): state 0 0 Heat Ex 2 14,505 0 W CV m h 3 h 4 ) 504.71 236.02 BTU lb m 1 hp 2545 B tu / hr 14, 505 hp Sec 4.11: System Integration 18 Example: (4.103) (a) Power required for the compressor, in hp, (b) Power output of the turbine, in hp, (c) Thermal efficiency of the cycle state 1 AV (ft3/min) h (BTU/lb) 3 4 30,000 p (atm) T (°R) 2 p2>p1 p3=p2 1 520 650 2000 980 155.51 504.71 Q W Compressor 0 -1687 18,851 0 0 14,505 Heat Ex 1 1 124.27 state Turbine Heat Ex 2 236.02 0 Find Q23 Energy Balance around heat exchanger: dE CV dt Q CV W CV Q C V 137 394 lb m hr 2 v m h gz 2 504.71 155.51 W Turbne W Compressor Q HeatEx Q C V m h3 h 2 BTU lb m hp 2545 B tu / hr 14 ,505 1687 18 ,851 18, 851 hp 0 . 68 Sec 4.9: Heat Exchangers (Revisited) 19 Example: (4.78) As sketched in the figure, a condenser using river water to condense steam with a mass flow rate of 2x105 kg/h from saturated vapor to saturated liquid at a pressure of 0.1 bar is proposed for an industrial plant. Measurements indicate that several hundred meters upstream of the plant, the river has a volumetric flow rate of 2x105 m3/h and a temperature of 15°C. For operation at steady state and ignoring changes in KE and PE, determine the river-water temperature rise, in °C, downstream of the plant traceable to use of such a condenser, and comment. Sec 4.9: Heat Exchangers (Revisited) 20 Example: (4.78) state state state Pl,i Pl,i Pl,i Pl,e Pl,e Pl,e AV Av(m (m333/h) /h) Av (m /h) m m(kg/h) (kg/h) m (kg/h) R,i R,i R,i R,e R,e R,e 2x10 2x10555 2x10 2x10 2x10555 2x10 000 000 ??? 2x10 2x10555 2x10 2x10 2x10555 2x10 111 000 pPP(bar) (bar) (bar) 0.1 0.1 0.1 0.1 0.1 0.1 TTT(°C) (°C) (°C) 45.81 45.81 45.81 45.81 15 15 15 hhh(kJ/kg) (kJ/kg) (kJ/kg) 2584.7 191.83 62.99 xxx Look up intensive properties for water from Tables based on known property values From Table A-2 : Properties of Saturated Water mR AV R vR 2 10 5 m3 1 .0 0 0 9 1 0 2 1 0 kg / h r 8 h 3 m 3 kg Sec 4.9: Heat Exchangers (Revisited) 21 Example: (4.78) state Pl,i Pl,e Av (m3/h) m (kg/h) x P (bar) T (°C) Using the energy balance simplified for a heat exchanger h (kJ/kg) R,i R,e 2x105 2x105 2x105 2x105 2x108 2x108 1 0 0 0 0.1 0.1 45.81 45.81 15 ? 2584.7 191.83 62.99 From Table A-2 : Properties of Saturated Water (p817 & 819) dE CV dt Q CV W CV 2 v m h gz 2 0 m P l h P l ,i h P l , e m R h R ,i h R , e h R , e h R ,i m Pl mR h P l ,i hP l ,e Sec 4.9: Heat Exchangers (Revisited) 22 Example: (4.78) state Pl,i Pl,e Av (m3/h) m (kg/h) h R ,e h R ,i h R , e 6 2 .9 9 m Pl m R kJ kg h Pl , i 5 8 2x105 2x105 0 0 ? 2x105 1 0 P (bar) 0.1 0.1 T (°C) 45.81 45.81 15 h (kJ/kg) 2584.7 191.83 62.99 h Pl , e 2 10 2 10 R,e 2x105 x Plugging known values: R,i From Table A-2 : Properties of Saturated Water (p817 & 819) kg / h r kg / h r 2 5 8 4 .7 1 9 1 .8 3 kJ 6 5 .3 8 kg Using this value, the exit temperature may be found from Table A-2. TR,e = 15.6°C giving a temperature rise of 0.6 °C kJ kg 23 end of Lecture 18 Slides