fibers for composites final

advertisement

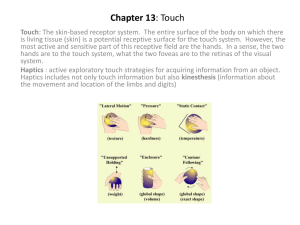

+ Figures taken from: P.K. Mallick. Fiber-Reinforced Composites, Materials, manufacturing, and design. 3rd Ed., CRC Press. 2008 Introduction to composites - fibers CME/MSE 404G. Polymeric Materials Fall 2012 fibers + fibers 2 + fibers 3 + fibers 4 + fibers 5 + fibers 6 + fibers 7 + fibers 8 + 9 Properties of commercial fibers fiber D, mm g/cmt Et, GPa Yt, GPa % strain COTE Poisson ’s ratio average values from manufacturers E-glass 10 2.54 72.4 3.45 4.9 5 0.2 S-glass 10 2.49 86.9 4.3 5 2.9 0.22 PAN, T300 7 1.76 231 3.65 1.4 -0.6 0.2 Pitch, P55 10 2.0 380 1.90 .5 -1.3 NA Kevlar 49 11.9 1.45 131 3.62 2.8 -2 NA Spectra 900 38 0.97 117 2.59 3.5 NA NA fibers + 10 Fibers: 2012 references; new research on fibers for composites % # 168 121 54 38 38 30 29 23 20 17 17 17 16 15 13 13 13 12 11 11 10 fibers 24.5% 17.6% 7.9% 5.5% 5.5% 4.4% 4.2% 3.4% 2.9% 2.5% 2.5% 2.5% 2.3% 2.2% 1.9% 1.9% 1.9% 1.7% 1.6% 1.6% 1.5% material carbon silicon carbide graphite aluminum silicon copper aluminum oxide polypropylene silica zirconium oxide titanium tungsten polyethylene pearlitic steel zirconium carbide titania polyacrylonitrile nickel molybdenum silver titanium carbide + In-class exercise fibers 11 + 12 Each team is to find composites applications for their fibers # fibers % 168 121 54 38 38 30 29 23 20 17 17 17 16 15 13 13 13 12 11 11 10 24.5% 17.6% 7.9% 5.5% 5.5% 4.4% 4.2% 3.4% 2.9% 2.5% 2.5% 2.5% 2.3% 2.2% 1.9% 1.9% 1.9% 1.7% 1.6% 1.6% 1.5% material carbon silicon carbide graphite aluminum silicon copper aluminum oxide polypropylene silica zirconium oxide titanium tungsten polyethylene pearlitic steel zirconium carbide titania polyacrylonitrile nickel molybdenum silver titanium carbide team 007 banana slugs dream team effervescent nostrils Group 5 grulkinators half n half pink flamingos team spiderman x-factor day late x-factor team spiderman pink flamingos half n half grulkinators Group 5 effervescent nostrils dream team banana slugs 007 assignments + 13 # % 168 121 fibers material 24.5% carbon 17.6% silicon carbide team 007 banana slugs 54 38 7.9% graphite 5.5% aluminum 38 5.5% silicon dream team effervescent nostrils Group 5 30 4.4% copper grulkinators 29 23 20 4.2% aluminum oxide 3.4% polypropylene 2.9% silica half n half pink flamingos team spiderman 17 17 2.5% zirconium oxide 2.5% titanium x-factor day late 17 silk 2.5% tungsten day late x-factor 16 15 2.3% polyethylene 2.2% pearlitic steel team spiderman pink flamingos 13 1.9% zirconium carbide half n half 13 13 12 1.9% titania 1.9% polyacrylonitrile 1.7% nickel 11 1.6% molybdenum grulkinators Group 5 effervescent nostrils dream team 11 1.6% silver banana slugs 10 1.5% titanium carbide 007 applications aerospace, wind turbines,… structural components - IC engines, aerospace, fusion graphite epoxy - space applications wall panels, replace Au, Ag in yarns textiles, photovoltaics, rechargeable batteries brake pads, linings, high friction applications fiber FP, ultrasound lasers, nextel 610 microcracks in concrete thermal shock, turbine blades, asbestos substitute, optical fibers coating in connectors for optical fibers bone implants M-M- composites, flameresistant paper? biomedical engineering, drug delivery W fiber copper composites - heat sinks, high stress applications fishing line, orthodontics, yachts reinforced grout, high impact gray cast iron in carbon composites, ablation - wear at high T, space craft pigment additive, photocatalysts aircraft, yachts, sporting goods mitigate electronic interference, integrated strain gage, conductors + nickel, sintered to glass optic fibers, high resiliency antibacterial - cellulose composites, rubber stabilizer gas turbine engines, airframes Team responses + 14 Fiber bundles Typical fibers have very small diameters, so that fiber bundles are used for ease of handling. Untwisted = strand, end (glass & Kevlar fibers); =tow (carbon fibers) Twisted = yarn fibers + 15 Single fiber test ASTM D3379 - ASTM D3379-75(1989)e1 Standard Test Method for Tensile Strength and Young's Modulus for High-Modulus Single-Filament Materials (Withdrawn 1998) A single filament is mounted along the centerline of a slotted tab using adhesive at each end The tab ends are gripped in the tensile machine and the midsection is cut Constant loading rate until failure fibers + 16 Single fiber mounting for tensile test fibers + 17 Tensile property determinations fibers Definitions Fu – force at failure Af = average filament cross-sectional area (planimeter measurement via photos of filament ends Lf = gage length C = true compliance (via loading rate) Fu s fu = Af Lf Ef = C × Af Tensile strength Tensile modulus + 18 Typical tensile strengths of fibers Typical fibers have high strength, high orientation Stress-strain curves are nearly linear up to failure Most fail brittlely Most fibers are prone to damage with handling and with contact to other surfaces fibers + 19 Model for fiber tensile strengths fibers + 20 Model application fibers + 21 Typical applications: Weibull distribution Time to failure: failure rate is proportional to time raised to the nth power, k=n+1 Cases 0 < k < 1: failure rate decreases with time. Example = infant mortality or early failure of electrical circuits k = 1: failure rate is constant over time. Example = random external events fibers k > 1: failure rate increases with time. Example = aging process + 22 Weibull: probability density In-class question: Interpret each curve with respect to a time-to-failure data set. Hint: the integral of each curve = 1. fibers + 23 Weibull: cumulative distribution In-class question: Interpret each curve with respect to a time-to-failure data set. Hint: the upper limit of each curve = 1. fibers + 24 Failure rates 5 failure rate 4 3 k=0.5 k=1 k=1.5 k=5 2 1 0 0 1 2 Time fibers 3 + 25 Quantile plots fibers + 26 Figure 2.4 fibers + 27 Example data: failure strength at a given fiber length fibers + 28 Weibull distribution fibers + fibers 29 + 30 Quantile plots Modmor data 3 data quan les 2 1 0 -1 5 -2 -3 6 7 8 Modmor model Modmor data -4 -5 fibers 9 ln(Tensile strength) 10 + 31 Problem 2.5. Mallick fibers MSE 599 P2_5.xlsx + Analysis of flaws in high- strength carbon fibres from mesophase pitch Janice Breedon Jones, John Barr, Robert Smith, J. Materials Sci., 14, (1980), 2455-2465 fibers 32 + 33 Data taken at two guage lengths, 20 mm and 3.2 mm fibers + 34 Effect of gauge length on strength why should there be an effect? fibers + fibers 35 + fibers 36 + fibers 37 + fibers 38 + 39 Single mode of failure should show similar Weibull plot slopes Similar slope suggests the same failure modes for each gauge length fibers + 40 Extrapolate to 0.3 mm length expected load transfer length for multifilament fibres of this diameter (3.8 Gpa) If the failure mechanisms are similar, we can extrapolate the tensile strength to shorter gauge lengths, estimating the tensile strength for lengths that are difficult to measure experimentally. fibers Flaw strength distributions and + statistical parameters for ceramic fibers: the normal distribution M. R’Mili, N. Godin, J. Lamon, Phys. Rev. E, 85, 051106 (2012) Large sets of ceramic fibre failure strengths from tows of 500 – 1000 filaments Flaws generated by ultrasonic Flaw strengths are distributed normally fibers 41 + 42 SiC-based Nicalon filaments fibers + 43 Quasi-linear regression failure of fiber tows For probabilities less than 4%, there is an underestimate of the number of first failures. This is likely due to the detection of low energy events near the filtering threshold. This is probably not a bimodal distribution of flaws. fibers + 44 Comparison of model and fiber failure data Very good indeed. fibers + 45 General effect of aspect ratio on tensile strength fibers + 46 Dry glass bundle. 3000 filaments Single filament shows a linear stress-strain curve. Bundle shows a nonlinear stress-strain curve prior to maximum stress, and progressive failure after maximum stress. Both effects are due to statistical distribution of the filament strengths. Some fail as the load increase. After the maximum stress, highly loaded fibers continue to fail, but not all at once fibers + Fiber production Glass fibers fibers 47 + fibers 48 + 49 Types of glass fibers tensile strength = 3.45 GPa; surface flaws reduce this to 1.72 GPa Continuous strand roving [strand = parallel filaments, n > 204] Woven roving [roving = group of untwisted strans/ends wound on a cylindrical forming package] Chopped strands – continuous strands cut to specific lengths; 3.2 – 12.7 for injection molding Chopped strand mats - 50.8 mm for chopped strand mats Woven roving mat Milled glass fibers, 0.79 to 3.2 mm; plastic fillers fibers + fibers 50 + fibers 51 + fibers 52 + fibers 53 + fibers 54 + fibers 55 + fibers 56 + fibers 57 + 58 Glass fiber compositions fibers + 59 Glass fiber properties fibers + 60 Sizing chemistries fibers + fibers 61 + fibers 62 + fibers 63 + fibers 64 + fibers 65 + Boron fibers fibers 66 + fibers 67 + fibers 68 + Boron Fiber http://specmaterials.com/boronfiber.htm 69 CONTACT US | DIRECTIONS HOME ABOUT US PRODUCTS PRICE LISTS APPLICATIONS USE & SAFETY CONTACT US SEARCH THIS SITE Specialty Materials, Inc. BORON FIBER Produced in single-filament reactors by Chemical Vapor Deposition (CVD), boron fiber exhibits a unique combination of High Strength, High Modulus and Large Diameter. Boron Fiber Properties Boron Prepreg Tape Prepreg Properties Hy-Bor® Prepreg Tape Hy-Bor® Prepreg Tape Properties Hy-Bor® Properties vs Standard Preforms Boron Compression Strength Analysis Hy-Bor® Fiber Count and Compression Strength Compression Strength After Impact for Hy-Bor® Elemental boron is deposited on a fine tungsten wire substrate and produced in diameters of 4.0-mil (102-micron) and 5.6-mil (142-micron). The resulting fiber is essentially amorphous boron with a fully borided-tungsten core. The textured surface provides an excellent interface in resin-matrix composites, eliminating any need for sizing treatments. Primarily used in resin-matrix composites it is available as a unidirectional prepreg tape with 250ºFand 350ºF cure epoxies. home | about us | products | applications | use & safety | contact us | directions | site map | press SPECIALTY MATERIALS, INC. 1449 Middlesex Street Lowell, Massachusetts 01851 Phone: 978-322-1900 • Fax: 978-322-1970 Email:info@specmaterials.com fibers Unidirectional Dry Woven Boron Boron Fiber Neutron Shielding Properties + 70 http://www.angelfire.com Boron Fibers Boron is an inherently-brittle material. It is commercially made by chemical vapor deposition of boron on a substrate, that is, boron fiber as produced is itself a composite fiber. In view of the fact that rather high temperatures are required for this deposition process, the choice of substrate material that goes to form the core of the finished boron fiber is limited. Generally, a fine tungsten wire is used for this purpose. A carbon substrate can also been used. The first boron fibers were obtained by Weintraub by means of reduction of a boron halide with hydrogen on a hot wire substrate. The real impulse in boron fiber fabrication, however, came only in 1959 when Talley used the process of halide reduction to obtain amorphous boron fibers of high strength. Since then, the interest in the use of strong but light boron fibers as a possible structural component in aerospace and other structures has been continuous, although it must be admitted that this interest has periodically waxed and waned in the face of rather stiff competition from other so-called advanced fibers, in particular, carbon fibers. fibers + 71 synthesis Reduction of boron Halide : Hydrogen gas is used to reduce boron trihalide: 2BX3 + 3 H2 = 2 B + 6 HX where X denotes a halogen: Cl, Br, or 1. In this process of halide reduction, the temperatures involved are very high, and, thus, one needs a refractory material, for example, a high melting point metal such as tungsten, as a substrate. It turns out that such metals are also very heavy. This process, however, has won over the thermal reduction process despite the disadvantage of a rather high-density substrate (the density of tungsten is 19.3 g cm -3) mainly because this process gives boron fibers of a very high and uniform quality. There are many firms producing boron fibers commercially using this process. In the process of BCI3, reduction, a very fine tungsten wire (10-12 micron diameter) is pulled into a reaction chamber at one end through a mercury seal and out at the other end through another mercury seal. The mercury seats act as electrical contacts for resistance heating of the substrate wire when gases (BCl3, + H2,) pass through the reaction chamber where they react on the incandescent wire substrate. The reactor can be a one- or multistage, vertical or horizontal, reactor. BCl3 , is an expensive chemical and only about 10% of it is converted into boron in this reaction. Thus, an efficient recovery of the unused BCl3, can result in a considerable lowering of the boron filament cost. fibers + Kevlar fibers 72 + fibers 73 + fibers 74 + fibers 75 + fibers 76 + fibers 77 + fibers 78 + fibers 79 + fibers 80 + fibers 81 + fibers 82 + 83 Carbon fibers Graphitic orientation a. Circumferentially orthotropic b. Radially orthotropic c. Transversely isotropic d. Circumferential + radial e. Circumferential + random fibers + 84 Carbon fibers In-class question: the most common orientation for pitch fibers Graphitic orientation a. Circumferentially orthotropic b. Radially orthotropic c. Transversely isotropic d. Circumferential + radial e. Circumferential + random fibers + fibers 85 + Filament failure under compression fibers 86 + 87 Compression failure cannot be determined directly by simple compression tests on filaments Indirect methods are used, such as the loop test, in which a filament is bent into a loop until it fails. The compressive strength is determined from the compressive strain at the fiber surface. fibers + 88 Fiber compressive strength fiber Tensile strength, GPa Compressive strength, GPa E-glass 3.4 4.2 PAN T-300 3.2 2.7-3.2 AS4 carbon 3.6 2.7 GY-70 carbon 1.86 1.06 P100 carbon 2.2 0.5 Kevlar 49 3.5 0.35-0.45 Boron 3.5 5 fibers + 89 Effect of fiber diameter on strength Explain this phenomena fibers + 90 Effect of fiber diameter on strength Fiber that are formed by spinning processes usually have increased strength at smaller diameters due to the high orientation that occurs during processing. fibers