GravityVehicle-workshop

advertisement

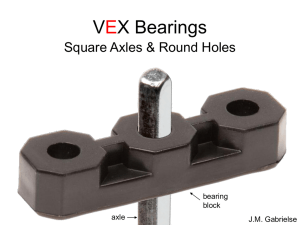

GRAVITY VEHICLE SCIENCE OLYMPIAD 2012 Coaches Workshop October 22, 2011 EGG-LESS SCRAMBLER Similar to former event “The Scrambler” Come closest to reaching target Scoring based on time and distance Lowest score wins Distance announced after impound Braking mechanism can be employed No electrical components Major Differences: Propelled only by its own mass (gravitational potential energy) Teams must build ramp with release mechanism CONSTRUCTION: THE RAMP Material: smooth to reduce friction (waste energy) Plastic, metal, wood, plexiglas, etc Too smooth=bad tracking Ideally adjustable Perhaps hinged to adjust slope (i.e. lounge chair) Shape: Where is mass concentrated? Flat- simple design, easily adjustable Curved- maximize PEg CONSTRUCTION: VEHICLE— CHASSIS Rigid is good– propulsion will cause stress Material: plastic, wood, metal, plexiglas, etc Structure: flat board, box style… Make sure axles are ‘square’ to direction of travel and parallel to each other Design idea: Build car in 2 halves with bolt connecting axles CONSTRUCTION: VEHICLE — AXLES Rigid and straight Crooked axle = crooked path Materials: wooden/plastic dowels, metal rods Axle-Chassis attachment: 1.) Drill holes in chassis, feed axle through 2.) Attaches tubes to chassis– straws CONSTRUCTION: VEHICLE — WHEELS Friction is the enemy Straight and light-weight Ideas: CDs- spin well, but need traction Strips of latex balloon Hobby airplane wheels Home-made– only if perfectly circular How many? 3 or 4? Thick or thin? Depends on chassis design BRAKING — GENERAL PRINCIPLES Braking mechanism can’t be used to propel vehicle Don’t lose contact/normal force Higher normal force=faster braking Keep center of mass closer to front axle Minimize Skidding Kinetic friction dependent wheel-surface friction instead of braking mechanism Decreases stability Fix it by relocating/adding mass- modeling clay Brake pads for smoother stops Too much brake=Newton’s 3rd Law Take tips from Scrambler CONSTRUCTION: BRAKING SYSTEMS — STRING METHOD String from one axle unwinds and wraps around the second axle. Fed through, axles lock, car stops. Distance traveled controlled by the amount of string. Easy construction Easy to implement Easy length adjustment Poor accuracy Backlash wrapping variation When string goes taut Skid Relies on wheel traction CONSTRUCTION: BRAKING SYSTEMS — THREADED ROD METHOD Uses a threaded rod for the axle, wing nut on the axle. Rotation of wheels = horizontal motion wing nut. Wing nut reaches a barrier, stops the axle. Distance set by wing nut placement. High accuracy Consistency Easy length adjustment Little backlash Harder to build Axle friction Skid GENERAL TIPS Test on various surfaces—gym floors, hallway tile Chart data for each; better idea on race day Clean floor— dirt/dust affects braking Calculations– divide race length by wheel circumference to get # of rotations TEST and TEST AGAIN! Don’t DQ! Read rules carefully Dimensions include starting point Release mechanism- actuated by pencil No loose pieces Vehicle mass < 2.500 kg Have fun! Event Coordinator: Betsy White– bwhite6@utk.edu