Stress - oscar

advertisement

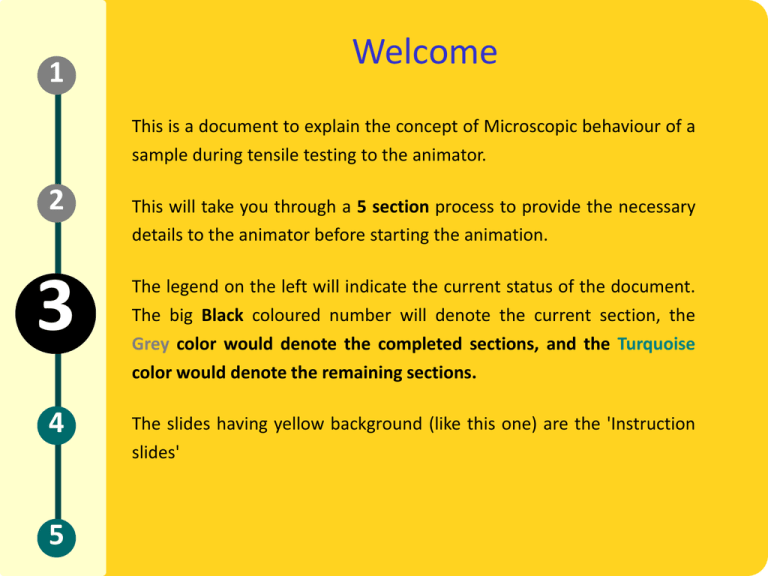

1 Welcome This is a document to explain the concept of Microscopic behaviour of a sample during tensile testing to the animator. 2 This will take you through a 5 section process to provide the necessary details to the animator before starting the animation. 3 The legend on the left will indicate the current status of the document. The big Black coloured number will denote the current section, the Grey color would denote the completed sections, and the Turquoise color would denote the remaining sections. 4 The slides having yellow background (like this one) are the 'Instruction slides' 5 Microstructure changes during Deformation This idd shows us the basic microscopic changes that take place in a sample when tensile forces are applied Related LOs: > Prior Viewing –Tensile Deformation of Ductile Metal Prerequisites: Basic phenomenon of tensile test Course Name: Mechanical Behaviour of Materials Level(UG): Author Sudip Deb Mentor Prof P.Pant Learning Objectives After interacting with this Learning Object, the learner will be able to: Identify the microscopic state of the sample when tensile stress is being applied to it. Identify the microscopic changes that lead to the failure of a material. •Differentiate between ductile and brittle fracture • • Definitions and Keywords 1 Stress: Stress is defined as force per unit area. It has the same units as pressure, and in fact pressure is one special variety of stress. • 2 3 Strain: Strain is defined as the amount of deformation an object experiences compared to its original size and shape. For example, if a block 10 cm on a side is stretched so that it becomes 11 cm long, the strain is (11-10)/10 or 0.1 (sometimes expressed in percent, in this case 10 percent.) Note that strain is dimensionless. • Elastic deformation: This type of deformation is reversible. Once the forces are no longer applied, the object returns to its original shape. • Plastic deformation: This type of deformation is not reversible. However, an object in the plastic deformation range will first have undergone elastic deformation, which is reversible, so the object will return part way to its original shape. • 4 5 1 Definitions and Keywords Ductility is a solid material's ability to deform under tensile stress; this is often characterized by the material's ability to be stretched into a wire 2 Necking The reduction in diameter that occurs as a sample material is subjected to tensile stresses. Fracture: Fracture is the (local) separation of an object or material into two, or more, pieces under the action of stress. 3 4 5 Brittleness: A material is brittle if, when subjected to stress, it breaks without significant deformation (strain) Ductile Fracture :In ductile fracture, extensive plastic deformation (necking) takes place before fracture. The terms rupture or ductile rupture describe the ultimate failure of tough ductile materials loaded in tension Slide 3 Introduction Tab 02 Tab 03 Tab 04 Tab 05 Tab 06 Tab 07 Name of the section/stage Interactivity area • • Ductile Brittle Ductile Iron Rod Brittle glass Rod Instructions/ Working area Credits 1 2 Master Layout 1: Universal Testing Machine 3 4 5 http://www.ndt-ed.org/EducationResources/CommunityCollege/Materials/Mechanical/Tensile.htm http://www.directindustry.com/prod/instron/tensile-compression-testing-machine-18463-41713.html 1 Step 1: T1: Choosing the sample Fig 1.1 Fig 1.2 Clasps 2 START 3 4 Universal Testing Machine Interactivit y type (IO 1/IO 2) Instruction to learners Button click Select the material on which the test is to be performed Ductile Iron Rod Instruction to animators o o o 5 Brittle Rod o As the experiment starts the Universal testing machine and the two rods appear on the screen The learner needs to select one among the two rods either the ductile specimen or the brittle one Once the selection is done the sample is shown being placed between the clamps of the machine As the selected specimen is placed in the machine and start button appears and also the graph of stress and strain Results and output If the ductile specimen is selected the n show the message Ductile specimen is being loaded • Else if the brittle specimen is selected show the message •Brittle specimen is being loaded 1 2 Master Layout 2(Ductile): Universal Testing Machine 3 4 5 http://www.ndt-ed.org/EducationResources/CommunityCollege/Materials/Mechanical/Tensile.htm http://www.directindustry.com/prod/instron/tensile-compression-testing-machine-18463-41713.html 1 Step 2.1: T1: Tensile Test for ductile material - stress – strain curve Stress A0 L0 2 Clasps Original START 3 4 Interactivit y type (IO 1/IO 2) Instruction to learners Instruction to animators 1. Notice the initial length L0 and the initial area of the specimen A0. •Mark and show L0 andA0 in the sample •Show the sample being placed in the machine • Show the zoomed up Lo part of the rod in between the machine clasps. 2. Click on red button to start the experiment • The learner clicks on the red button • As the red button is clicked the button vanishes the graph starts but no significant change in the sample is seen and it stops as the graph reaches the orange dot • Show instruction to learner 2. • 5 • On reaching the orange dot a pop up is shown from the magnified image of the specimen which shows the microstructure of steel Display test 3 to the learner and start button reappears Text to be displayed 1. Stress is a function of Load / cross sectional area (A0) 2. Strain is defined as the change in length/ original length on application of load. L1- L0 L0 3. This is the microstructure of steel within the elastic limit 1 Step 2.2: T1: Tensile Test for ductile material - stress – strain curve Stress A rod L1 L 1 2 Clasps START 3 4 Interactivit y type (IO 1/IO 2) Instruction to learners Click the start button for further loading 1. Instruction to animators o o o 5 o Once the start button is clicked the microstructure is removed and also the start button and the loading phenomenon starts again and also the graph starts moving This time there is some change in the dimensions of the sample its length increases by 1 cm This continues till the graph reaches the blue dot where this stops the text 1 is displayed to the learner Then a pop up is shown from the elongated sample showing the microstructure of the elongated sample and also text 2 is displayed and start button reappears Text to be displayed The maximum elastic limit of the sample has been reached and plastic deformation in the sample has started as length increased from Lo to L1 . 1. 2.This is the microstructure of the sample in the plastic region .the grains are elongated. 1 Step 2.3.1: T1: Tensile Test for ductile material - stress – strain curve Stress Necking 2 Clasps START 3 Interactivit y type (IO 1/IO 2) Instruction to learners Click the start button for further loading 1. Instruction to animators o o 4 o o 5 Once the start button is clicked the microstructure is removed and also the start button is removed and the material starts being stretched the graph also starts moving also the sample starts to elongate further a blue dot appears on the screen (text 1 appears) the loading continues and stops midway after sometime necking is seen to appear in the sample and text 1 is displayed to the learner Text to be displayed The Ultimate Tensile Strength of the material has been reached and is indicated by the blue dot 2. 2.Necking is seen to appear on the surface of the material 1. 1 Step 2.3.2: Deformation due to dislocation 2 2 3 Interactiv ity type (IO 1/IO 2) Click Instruction to animators Results and output •As necking start appearing in the earlier slide simultaneously show the first fig with the dots in it • then as necking progress the show necking occurring in this sample also with the size of the voids increasing 4 •Next show the voids increasing in size •After that show the voids coalescing with each other and growing in size also show the area near the voids narrowing up. •Finally Show the sample ruptured and label it as deformation due to dislocation 5 1. Deformation of a material by the method of void formation. 1 Step 2.4: T1: Tensile Test for ductile material - stress – strain curve Stress Crack 2 L 4 Clasps START 3 4 5 Interactivit y type (IO 1/IO 2) Instruction to learners Click the start button for further loading 1. Instruction to animators o o o o o Once the start button is clicked it is removed the graph starts moving also the sample starts to tear up from the necked region Text one is displayed As the material starts tearing apart Text 2 and text 3 are displayed Text to be displayed Cracks being formed on the sample 1. Facture or Failure The material starts to crack once it has crossed its ultimate tensile strength until the point of complete failure or fracture of the material. 2.Microstructure of the fractured sample 1. 1 Step 3.1: T1: Tensile Test for brittle material - stress – strain curve Stress A0 L0 2 Clasps Original Fractured Region START 3 4 Interactivit y type (IO 1/IO 2) Instruction to learners Notice the initial length L0 and the initial area of the specimen A0. 2.Click on red button to start the experiment 1. Instruction to animators Mark and show L0 andA0 in the sample Show the sample being placed in the machine • Show the zoomed up Lo part of the rod in between the machine clasps. • • • Show instruction to learner 2. The learner clicks on the red button As the red button is clicked it vanishes the graph starts but no significant change in the sample is seen and it stops as the graph reaches the orange dot Text to be displayed Stress is a function of Load / cross sectional area (A0) 1. Strain is defined as the change in length/ original length on application of load. 1. • • 5 On reaching the orange dot the sample suddenly breaks showing the phenomenon of brittle fracture •Display test 3 to the learner and mark the fractured region • 3. Brittle fracture has occurred in the element 1 Step 3.2: T1: Tensile Test for brittle material - Microstructure 2 3 microscopic Image Zoom in type http://pwatlas.mt.umist.ac.uk/internetmicroscope/micrographs/failure/brittle-steel_z9.html Interactivi ty type 4 5 SEM image Instruction to learners Instruction to animators o Zoom in type o o Take the fractured sample. Zoom into the fractured region of the sample and show the schematic image to the learner Further zoom into the image shown and SEM image to the learner. Text to be displayed 1. Notice the various regions of the fractured sample and also the region along which fracture has taken place 2. SEM image shows more detailed into the fractured regions 1 Step 4: Types of Brittle fracture Schismati c Image 2 http:// 3 4 Transgranular Interactivi ty type (IO 1/IO 2) Instruction to animators Show two completely intact images of grains simultaneously (images on the right without the black cracks) Text to be displayed • Point out In one of the grains show it cracking along the grain label it as transgranular • In the other one show the crack propagating along the grain boundaries (blue lines) label it as intergranular • 5 Intergranular Observe the Differences Transgranular Fracture-Fracture along the grain Intergranular Fracture-Fracture along the grain boundary 1.One of the two fractures has occurred in the above case 1. APPENDIX 3 1 2 3 4 5 Questionnaire 1. Which of the following components will take the maximum time for fracture? Answers: a) Steel b)Wood c) Plastic d) Glass 2. Phenomenon of necking occurs in? Answers: a)Brittle Cast Iron b)Stainless Steel c) Dolomite d) Graphite 3. Ductile Fracture occurs basically due to? Answers: a)Rusting b)Grain boundary fracture c) Corrosion d) Void Formation 4.Which of this is absent in Brittle metals ?(multiple choice) Answers: a) Yield Strength b) Plastic deformation c) Fracture d)Necking 1 Instruction to Animators 2 Master layout 1 shows both the ductile and the brittle sample out of which one has to be selected . If the ductile specimen is selected then the slides 9-14 are shown to the learner. •The Slide 14 is to be shown if ductile specimen is selected this shows the specific process of void formation which leads to ductile fracture. •Slide 15-16 are shown if the brittle specimen is selected. •In both the cases the microstructures are to be shown as zoomed out from the specimen itself. •Slides 17-18 should be shown to the user to find the difference in both the processes. • • 3 4 5 APPENDIX 2 Links for further reading Reference websites: http://www.substech.com/dokuwiki/doku.php?id=fracture_toughness http://www.engineersedge.com/strength_of_materials.htm http://www.feppd.org/ICB-Dent/campus/biomechanics_in_dentistry/ldv_data/basic.htm http://www.ndt-ed.org/EducationResources/CommunityCollege/Materials/Mechanical/Tensile.htm http://www.feppd.org/ICB-Dent/campus/biomechanics_in_dentistry/ldv_data/basic.htm Books: Mechanical Metallurgy – George E. Dieter Mechanical Behavior of Materials.- Thomas H. Courtney APPENDIX 3 Summary • Elastic deformation: • • The stress and strain initially increase with a linear relationship. In this region of the curve, when the stress is reduced, the material will return to its original shape. Yield point: From this point on in the tensile test, some permanent deformation occurs in the specimen. •Plastic deformation: The material will not return to its original, unstressed condition when the load is removed. •The ultimate tensile strength (UTS) or, more simply, the tensile strength, is the maximum engineering stress level reached in a tension test. •Failure/ Fracture: The point at which the material breaks. •Stiffness is resistance of a material to elastic deformation. The higher the elastic slope the higher the stiffness of the material. •Ductility is the maximum elongation before failure/ fracture. •