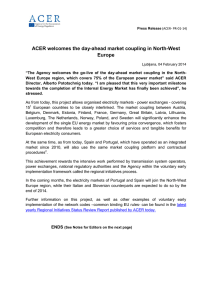

Modeling Interactions & Assemblies

advertisement

Joël Cugnoni, LMAF/EPFL, 2012 How can we model more complex cases ? ◦ It is possible to define interactions between different regions of a model by the means of additional equations that relate the degrees of freedoms of multiple nodes. Bilateral constraints to “glue” separate parts: Unilateral constraints: ◦ Node to node interaction : Equation constraint ◦ Node to surface interaction : Kinematic coupling ◦ Surface to surface interation: Tie constraint ◦ Contact: no penetration between two faces, friction & sliding => non linear behaviour, not in course Available in Interaction->Constraints->Equation one linear equation between several DOFs a1 Node1.DOF1 + a2 Node2.DOF2 + … = constant Antisymmetry 1 * Node17.U1 + 1 * Node23.U1 = 0 17 y Mechanism (Pulley) 1 * Node12.U2 - 1 * Node21.U1 = 0 23 21 14 x Available in Interaction->Constraints->Coupling->Kinematic coupling Multiple equations to keep relative position constant including rotations Tranfers the displacements / rotation of the Master node to slave surface Usually used with reference points to link parts or apply moments / rotation to one face Master Node : reference point with 6 DOFS Kinematic coupling y Slave Nodes : 3 DOFS x Available in Interaction->Constraints->Tie Multiple kinematic equations to keep relative position constant between each point of the master surface and their corresponding projection on the slave surface Usually used to link two parts of an assembly to ensure continuity of the displacements (approximation) Slave surface Small distance (projection tolerance) Projection lines Master surface y x Three methods: ◦ Continuous CAD model: Merge all parts in CAD -> export STP model -> import in Abaqus -> partition to differentiate the materials ◦ Merged geometry: model as an assembly in CAD -> export as STP -> import in Abaqus -> create assembly and position parts -> Merge geometry + keep internal interfaces ◦ Tie / coupling constraints: model as an assembly in CAD -> export as STP -> import in Abaqus -> create assembly and position parts -> Create Tie / coupling to model the interactions between parts See assembly1.cae Procedure: ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ open assembly1-input.cae create instance for piston and axe1 align axe1 with coaxial + face to face (-13mm offset) merge and keep interfaces add instance for biele1 align with coaxial +face2face +4mm offset assign properties to all parts / regions and then create step create 1st constraint: tie for axis to biele surfaces create datum point in the middle of lower biele axis create reference point create constraint: kinematic coupling btw RP and lower axis of biele boundary condition: pressure 0.1MPa on top of cylinder, all displacement & rotation constrained on RP mesh fused part with tets quad 2.8mm mesh biele with hexa sweep or wedges (partition by extending faces) run job show results with several cutting plane to show 1) mesh continuity between the merged parts 2) displacement continuity but mesh discontinuity where tie is used