Position Analysis - UJ

advertisement

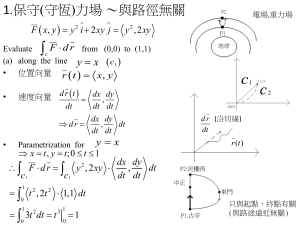

Mechanics of Machines Dr. Mohammad Kilani Class 3 Position Analysis TYPES OF MECHANISM ANALYSESE Position Analysis Position Analysis Given θ12 find θ23, θ34 and θ14 Find maximum and minimum values of θ14 . Find the location of each point on the mechanism for a given value of θ12 and the curve traced by the a point during motion. θ23 θ12 θ34 θ41 Velocity Analysis Position Analysis Given θ12 and ω12 find ω23, ω34 and ω14 Find the speed of a point in the mechanism θ 34, ω34 θ 23, ω23 θ 12, ω12 θ 41, ω41 Acceleration Analysis Position Analysis Given θ12 , ω12 and α12 find α23, α34 and α14 Find the acceleration of a point in the mechanism θ 34, ω34 , α34 θ 23, ω23 , α23 θ12, ω12, α12 θ 41, ω41 , α41 Question Why is acceleration analysis important? θ 34, ω34 , α34 θ 23, ω23 , α23 θ12, ω12, α12 θ 41, ω41 , α41 GRAPHICAL POSITION ANALYSIS Graphical Position Analysis Use graphical methods, (pen, ruler, compass and protractors to solve position analysis problems. CAD drafting methods may also be used as a convenient alternative. θ23 θ12 θ34 θ41 VECTOR POSITION ANALYSIS Vector Position Analysis Use vector loop closure equation to solve position analysis problems Loop Closure Equation Use vector loop closure equation to solve position analysis problems rP r2 r3 r1 r4 Planar Four Bar Loop Closure Equation How many scalar equations can be written from the vector loop-closure equation? How many unknowns can be solved for rP r2 r3 r1 r4 Planar Four Bar Loop Closure Equation How many scalar equations can be written from the vector loopclosure equation?: Two scalar equations could be written from a vector equation How many unknowns can be solved for: Two unknowns: In a standard problem, θ1 and θ2 are given. θ3 and θ4 are to be solved for. We will focus on planar mechanisms in this course rP r2 r3 r1 r4 Planar Four Bar Loop Closure Equation The closure condition expresses the condition that a loop of a linkage closes on itself. For the four-bar linkage shown the closure equation is r2 r3 r1 r4 r2 u 2 r3 u 3 r1u 1 r4 u 4 r2 cos 2 i sin 2 j r3 cos 3 i sin 3 j r1 cos 1 i sin 1 j r4 cos 4 i sin 4 j Planar Four Bar Loop Closure Equation The closure condition expresses the condition that a loop of a linkage closes on itself. For the four-bar linkage shown the closure equation is r2 r3 r1 r4 r2 u 2 r3 u 3 r1u 1 r4 u 4 r2 cos 2 i sin 2 j r3 cos 3 i sin 3 j r1 cos 1 i sin 1 j r4 cos 4 i sin 4 j The following two scalar equations are produced r2 cos 2 r3 cos 3 r1 cos 1 r4 cos 4 r2 sin 2 r3 sin 3 r1 sin 1 r4 sin 4 Analytical Solution when θ2 is known r2 cos 2 r3 cos 3 r1 cos 1 r4 cos 4 r2 sin 2 r3 sin 3 r1 sin 1 r4 sin 4 The above two equations could be solved for two unknowns. One approach is to eliminate one of the unknown angles by isolating the trigonometric function involving the angle on the left-hand side of the equation. r3 cos 3 r1 cos 1 r4 cos 4 r2 cos 2 r3 sin 3 r1 sin 1 r4 sin 4 r2 sin 2 Squaring both sides of both equations and using the identity sin 2 cos 2 1 we obtain r3 r1 r2 r4 2 r1 r4 cos 1 cos 4 sin 1 sin 4 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 Analytical Solution when θ2 is known r3 r1 r2 r4 2 r1 r4 cos 1 cos 4 sin 1 sin 4 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 To obtain an explicit expression for θ4 in terms of θ2 and the constant angle θ1 , we combine the coefficients of cos θ4 and sin θ4 in the equation above as follows: A cos 4 B sin 4 C 0 where A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 2 2 2 Analytical Solution when θ2 is known A cos 4 B sin 4 C 0 The above equation can be solved for θ4 by using the following half angle identities sin 4 cos 4 2 tan 4 2 4 2 4 2 tan 4 2 1 tan 1 tan 1 2 2 2 After substitution and simplification, we get C A t 2 Bt ( A C ) 0 2 where t tan 4 2 A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 2 2 2 Analytical Solution when θ2 is known C A t 2 Bt ( A C ) 0 2 A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 Solving for t we obtain t 4 B 4 C A C A 2B 2 2 C A or t B A B C 2 AC and 4 2 tan 1 t 2 2 2 2 2 Analytical Solution when θ2 is known Given the values of θ1 and θ2 for a four bar mechanism of known r1, r2, r3 and r4 the output angle θ4 is calculated as: A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 t B A B C 2 2 2 AC and 4 2 tan 1 t The ± sign identifies the two possible assembly modes of the linkage Analytical Solution when θ2 is known Given the values of θ1 and θ2 for a four bar mechanism of known r1, r2, r3 and r4 the output angle θ4 is calculated as: A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 t B A B C 2 2 2 AC and 4 2 tan 1 t The ± sign identifies the two possible assembly modes of the linkage Analytical Solution when θ2 is known Note that –π/2 ≤ tan-1 (t) ≤ –π/2. Therefore, θ4 will have the range –π ≤ θ4 ≤ –π. Unless the linkage is a Grashof type II linkage in one of the extreme positions of its motion range, there are two valid solutions for θ4. These correspond to two assembly modes or branches for the linkage. A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 t B A B C 2 AC and 4 2 tan 1 t 2 2 Analytical Solution when θ2 is known Because of the square root in the expression for t, it can be complex if (A2 + B2) < C2. In this case, the mechanism is a Grashof type II linkage in one of the extreme positions of its motion range and it cannot be assembled in specified values of θ1 and θ2 . The assembly configurations would then appear as shown below A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 t B A B C 2 AC and 4 2 tan 1 t 2 2 Analytical Solution when θ2 is known After θ4 is known, an expression for θ3 can be obtained by solving the loop closure equation to obtain: 3 tan 1 r1 sin 1 r4 sin 4 r2 sin 2 r1 cos 1 r4 cos 4 r2 cos 2 Note that it is essential that the sign of the numerator and denominator be maintained to determine the quadrant in which the angle θ3 lies. This can be done by using the ATAN2 function. The form of this function is: ATAN2 (sin θ3, cos θ3) r3 cos 3 r1 cos 1 r4 cos 4 r2 cos 2 r3 sin 3 r1 sin 1 r4 sin 4 r2 sin 2 A 2 r1 r4 cos 1 2 r2 r4 cos 2 B 2 r1 r4 sin 1 2 r2 r4 sin 2 C r1 r2 r4 r3 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 t B A B C 2 AC and 4 2 tan 1 t 2 2 Analytical Solution when θ2 is known Once all of the angular quantities are known, it is relatively straightforward to compute the coordinates of any point on the mechanism. In particular, the coordinates of Q,P, and R are given by rQ r2 r2 cos 2 i sin 2 j rp r2 r3 r2 cos 2 i sin 2 j r3 cos 3 i sin 3 j rp r1 r4 r1 cos 1i sin 1 j r4 cos 4 i sin 4 j rp r1 r1 cos 1i sin 1 j Analytical Solution when θ3 is known If the coupler angle θ3 is given, and θ2 and θ3 are to be determined, graphical solution will require an iterative trial and error solution. The analytical procedure, in contrast, follows exactly the same procedure as when θ2 is given. It starts by writing the loop closure equations with θ2 replacing θ3 as the variable to be eliminated. The equations set are of exactly the same form except that the indices 2 and 3 are interchanged. Therefore, we can use directly the position solution derived for the case of known θ2 while interchanging the indices 2 and 3. r3 cos 3 r1 cos 1 r4 cos 4 r2 cos 2 r3 sin 3 r1 sin 1 r4 sin 4 r2 sin 2 r2 cos 2 r1 cos 1 r4 cos 4 r3 cos 3 r2 sin 2 r1 sin 1 r4 sin 4 r3 sin 3 Analytical Solution when θ3 is known When the coupler angle θ3 is given, there is an assembly-mode ambiguity similar to that occurine when θ2 is given. It is necessary to know the appropriate mode of the linkage before the analysis is begun;. The mode is determined by the + or – sign used for the square root term when calculating t. Once the assembly mode is determined, it remains the same for any position of the input link unless the linkage is a class III linkage, and passes through a singular (indeterminate) position . r2 cos 2 r1 cos 1 r4 cos 4 r3 cos 3 r2 sin 2 r1 sin 1 r4 sin 4 r3 sin 3 Example: Position Analysis of a Four Bar Linkage A four bar linkage with r1 = 1, r2 = 2, r3 = 3.5, r4 = 4, and θ1 = 0, find θ3 and θ4 for each of the solution branches when the driving crank is in the positions θ2 = 0, π/2, π,and - -π/2. A 2 r1 r4 cos 1 2 r2 r4 cos 2 A 2 (1 )( 4 ) 2 ( 2 )( 4 ) 8 B 2 r1 r4 sin 1 2 r2 r4 sin 2 0 C r1 r2 r4 r3 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 C 1 2 4 3 . 5 2 (1 )( 2 ) 4 . 75 2 t t 2 B 2 2 A B C 2 2 2 AC 0 8 2 4 2 tan 0 4 . 75 2 8 4 . 75 1 0 . 5049 2 0 . 5049 53 . 58 Example: Position Analysis of a Four Bar Linkage A four bar linkage with r1 = 1, r2 = 2, r3 = 3.5, r4 = 4, and θ1 = 0, find θ3 and θ4 for each of the solution branches when the driving crank is in the positions θ2 = 0, π/2, π,and - -π/2. POSITION ANALYSIS FOR A RIGID BODY WHEN TWO POINTS ARE KNOWN Position Analysis for a Rigid Body When Two Points are Knows Given the kinematic properties of one point on a rigid body and the angular position, angular velocity, and angular acceleration of the body, we can compute the position, velocity, and acceleration of any defined point on the rigid body. For the rigid body shown. Assume that A and B are two points attached to an arbitrary link, say link 5, and a third point is defined relative to the line between points A and B by the angle β and the distance rC/A, which is represented as r6. Then the position of point C can be computed directly if rA and θ5 are known. Position Analysis for a Rigid Body When Two Points are Knows The position of point C is given as: rC rA r6 rA r6 cos 6 i sin 6 j where 6 5 If θ5 If is known, the equation above can be used to calculate the location of point C directly. We often know the position vectors of two points A and B on the rigid body. The value of θ5 can be calculated from the from the x and y components of the position vectors for A and B using 5 tan 1 rB y rA y r r Ax Bx POSITION ANALYSIS FOR A SLIDER-CRANK MECHANISM HW#2 (Prob. 4-6 and 4-7, with data in row (a) Table P4-1). (4-10, 4-12, 4-18(f)) Position Analysis for a Slider-Crank Mechanism Next to the fourbar linkage, the slider-crank is probably the most commonly used mechanism. It appears in all internal combustion engines and in numerous industrial and household devices. Position Analysis for a Slider-Crank Mechanism To develop the closure equations, locate vectors r2 and r3 as was done in the regular four-bar linkage. One of the other two vectors is taken in the direction of the slider velocity and the other is taken perpendicular to the velocity direction. The loop closure equation is rp r2 r3 r1 r4 r3 r4 r2 rp r1 Position Analysis for a Slider-Crank Mechanism Writing the loop closure equation in terms of the vector angles, we obtain r3 r2 r3 r1 r4 r2 u 2 r3 u 3 r1u 1 r4 u 4 r2 cos 2 i sin 2 j r3 cos 3 i sin 3 j r1 cos 1i sin 1 j r4 cos 4 i sin 4 j r4 r2 rp r1 where 4 1 2 Two scalar equations are produced. The equations can be solved for two unknowns. r2 cos 2 r3 cos 3 r1 cos 1 r4 cos 4 r2 sin 2 r3 sin 3 r1 sin 1 r4 sin 4 Position Analysis for a Slider-Crank Mechanism Unlike the four-bar linkage loop closure equations where all link lengths are known, the piston displacement r1 is an unknown in the slider-crank equation. The constraint resulting from a known r1 is replaced by the constraint θ4 = θ1 + π/2. r2 cos 2 r3 cos 3 r1 cos 1 r4 cos 4 r2 sin 2 r3 sin 3 r1 sin 1 r4 sin 4 r3 The following problem statements are possible Crank angle θ2 given , find θ3 and r1 Piston displacement r1 given, find θ2 and θ3 Coupler angle θ3 given, find θ2 and r1. r4 r2 rp r1 Analytical Solution when θ2 is known The analytical solution procedure follows the same major steps as in the four-bar linkage case. To eliminate θ3 , first isolate it in the loop closure equations as follows: r2 cos 2 r3 cos 3 r1 cos 1 r4 cos 4 r2 sin 2 r3 sin 3 r1 sin 1 r4 sin 4 r3 r3 cos 3 r1 cos 1 r4 cos 4 r2 cos 2 r3 sin 3 r1 sin 1 r4 sin 4 r2 sin 2 Squaring both sides of both equations and using the identity sin cos 1 we obtain 2 r4 r2 rp r1 2 r3 r1 r2 r4 2 r1 r4 cos 1 cos 4 sin 1 sin 4 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 Analytical Solution when θ2 is known r3 r1 r2 r4 2 r1 r4 cos 1 cos 4 sin 1 sin 4 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 The expression gives r1 in a quadratic expression involving θ2 and the other known variables. To obtain a solution, collect together the coefficients of the different powers of r1 as follows r3 r4 r2 rp r1 r1 Ar1 B 0 2 where A 2 r4 cos 1 cos 4 sin 1 sin 4 2 r2 cos 1 cos 2 sin 1 sin 2 B r2 r4 r3 2 r2 r4 cos 2 cos 4 sin 2 sin 4 2 2 2 Analytical Solution when θ2 is known r1 Ar1 B 0 2 where A 2 r4 cos 1 cos 4 sin 1 sin 4 r2 cos 1 cos 2 sin 1 sin 2 B r2 r4 r3 2 r2 r4 cos 2 cos 4 sin 2 sin 4 2 2 2 The expression for A could be simplified by noting that cos 1 cos 4 r3 sin 1 sin 4 r4 cos( 1 4 ) cos( 2 ) 0 giving A r2 cos 1 cos 2 sin 1 sin 2 r2 rp r1 Analytical Solution when θ2 is known r1 Ar1 B 0 2 where A r2 cos 1 cos 2 sin 1 sin 2 B r2 r4 r3 2 2 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 Solving for r1 gives r1 A A 4B 2 2 The ± sign indicates two possible assembly modes for the same θ2. Analytical Solution when θ2 is known Because of the square root in the expression for r1, it becomes complex when A2 < 4B. If this happens, the mechanism cannot be assembled in the position specified. A r2 cos 1 cos 2 sin 1 sin 2 B r2 r4 r3 2 2 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 r1 A A 4B 2 2 Analytical Solution when θ2 is known A r2 cos 1 cos 2 sin 1 sin 2 Once a value for r1 is determined, the closure equations can be solved for θ3 to give B r2 r4 r3 2 2 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 r3 cos 3 r1 cos 1 r4 cos 4 r2 cos 2 r3 sin 3 r1 sin 1 r4 sin 4 r2 sin 2 3 tan 1 r1 sin 1 r4 sin 4 r2 sin 2 r1 cos 1 r4 cos 4 r2 cos 2 As in the case of the four-bar linkage, it is essential that the signs of the numerator and denominator in the above expression be maintained to determine the quadrant in which the angle θ3 lies. r1 A A 4B 2 2 r3 r4 r2 rp r1 Analytical Solution when θ2 is known A r2 cos 1 cos 2 sin 1 sin 2 Once all of the angular quantities are known, it is relatively straightforward to compute the coordinates of any point on the vector loops used in the closure equations. B r2 r4 r3 2 r1 A A 4B 2 2 r3 rp r2 r3 r2 cos 2 i sin 2 j r3 cos 3 i sin 3 j 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 In particular, the coordinates of Q and P are given by rQ r2 r2 cos 2 i sin 2 j 2 r4 r2 rp r1 Analytical Solution when r1 is known The analytical solution procedure follows the same major steps as in the previous case. r1 r2 r4 r3 2 r1 r4 cos 1 cos 4 sin 1 sin 4 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 r2 r4 cos 2 cos 4 sin 2 sin 4 0 After eliminating θ3 from the loop closure equation, we simplify the resulting equation as follows r3 A cos 2 B sin 2 C 0 r2 where A 2 r1 r2 cos 1 2 r2 r4 cos 4 B 2 r1 r2 sin 1 2 r2 r4 sin 4 C r1 r2 r4 r3 2 r1 r4 cos 1 cos 4 sin 1 sin 4 2 2 2 2 r4 rp r1 Analytical Solution when r1 is known A cos 2 B sin 2 C 0 The trigonometric half-angle identities can be used to solve the equation above for θ2 . Using these identities and simplifying gives C A t 2 Bt ( A C ) 0 A 2 r1 r2 cos 1 2 r2 r4 cos 4 B 2 r1 r2 sin 1 2 r2 r4 sin 4 C r1 r2 r4 r3 2 2 2 2 r1 r4 cos 1 cos 4 sin 1 sin 4 sin 2 2 cos 2 where 2 t tan 2 2 2 tan 2 2 2 2 2 2 tan 2 2 1 tan 1 tan 1 2 2 2 Solving for t gives t t r3 4 B 4 C A C A 2B 2 2 C A B A B C 2 2 AC and 2 2 tan 1 t 2 r2 r4 rp r1 Analytical Solution when r1 is known A 2 r1 r2 cos 1 2 r2 r4 cos 4 t t 4 B 4 C A C A 2B 2 2 C A B A B C 2 2 2 AC and 2 2 tan 1 t The ± sign indicates two possible assembly modes. Typically, there are two valid solutions for θ2. Because tan-1 has a valid range of π/2 ≤ tan-1 (t) ≤ –π/2, θ2 will have the range –π ≤ θ2 ≤ –π. B 2 r1 r2 sin 1 2 r2 r4 sin 4 C r1 r2 r4 r3 2 2 2 2 2 r1 r4 cos 1 cos 4 sin 1 sin 4 Analytical Solution when r1 is known A 2 r1 r2 cos 1 2 r2 r4 cos 4 t t 4 B 4 C A C A 2B 2 2 C A B A B C 2 2 2 AC and 2 2 tan 1 t Because of the square root in the equation for the variable t , it becomes complex when (A2 + B2) < C2 If this happens, the mechanism cannot be assembled for the specified value of r1 . B 2 r1 r2 sin 1 2 r2 r4 sin 4 C r1 r2 r4 r3 2 2 2 2 2 r1 r4 cos 1 cos 4 sin 1 sin 4 Analytical Solution when r1 is known A 2 r1 r2 cos 1 2 r2 r4 cos 4 t t 4 B 4 C A C A 2B 2 2 C A B A B C 2 2 2 AC and 2 2 tan 1 t Knowing θ2 , the closure equations can be solved for θ3. As in the previous cases, it is essential that the signs of the numerator and denominator be maintained to determine the quadrant in which the angle θ3 lies. B 2 r1 r2 sin 1 2 r2 r4 sin 4 C r1 r2 r4 r3 2 2 2 2 2 r1 r4 cos 1 cos 4 sin 1 sin 4 Analytical Solution when θ3 is known When the coupler angle θ3 is the input link, the analytical procedure for solving the position equations follows the same major steps as when θ2 is the input. we can assume that θ1 , θ3, θ3 are known and that θ2 and r1 are to be found. The link lengths r2 and r2 and the angles θ1, and θ4 are constants. For the position analysis, again begin with the loop closure equations and isolate the terms with θ2 The resulting equations of the same form obtained when θ2 is the input except r2 cos 3 r1 cos 1 r4 cos 4 r3 cos 2 that the indices 2 and 3 are interchanged. r2 sin 3 r1 sin 1 r4 sin 4 r3 sin 2 Therefore, we can use directly the position solution derived for the case when θ2 is the input and interchange the indices 2 and 3. POSITION ANALYSIS FOR AN INVERTED SLIDER-CRANK MECHANISM Position Analysis for an Inverted SliderCrank Mechanism An inversion of the fourbar slider-crank linkage in which the sliding joint is between links 3 and 4 is shown. The slider block has pure rotation about point O4. Note that the angle between link 3 and link 4 is fixed and is equal to π/2, and that link 1 is assumed to be aligned with the xaxis of the reference coordinate, θ1 = 0. r3 r2 r1 r4 Position Analysis for an Inverted SliderCrank Mechanism To develop the closure equations, locate vectors r2 and r3 as was done in the original slider-crank linkage. The magnitude of r3 is variable depending on the location of the slider. Vectors r1 is taken in the direction of the ground link, and vector r4 is taken perpendicular to r3. The loop closure equation is r2 r3 r1 r4 r3 r2 r1 r4 Position Analysis for an Inverted SliderCrank Mechanism Writing the loop closure equation in terms of the vector angles, we obtain r2 r3 r1 r4 r2 u 2 r3 u 3 r1u 1 r4 u 4 r2 cos 2 i sin 2 j r3 cos 3 i sin 3 j r1 cos 1i sin 1 j r4 cos 4 i sin 4 j r3 r2 r1 r4 where 4 3 2 Two scalar equations are produced. The equations can be solved for two unknowns. r2 cos 2 r3 cos 3 r1 cos 1 r4 cos 4 r2 sin 2 r3 sin 3 r1 sin 1 r4 sin 4 Position Analysis for an Inverted SliderCrank Mechanism The piston displacement r3 is an unknown in the equation. The constraint resulting from a known r3 is replaced by the constraint θ4 = θ3 + π/2. cos 4 sin 3 cos 1 1 sin 4 cos 3 sin 1 0 The following problem statements are possible Crank angle θ2 given , find θ4 and r3 Piston displacement r3 given, find θ2 and θ4 Output angle θ4 given, find θ2 and r3. r3 r2 r4 r1 r2 cos 2 r3 sin 4 r1 r4 cos 4 r2 sin 2 r3 cos 4 r4 sin 4 Analytical Solution when θ2 is known The analytical solution procedure follows the same major steps as in the non-inverted slider crank. To eliminate θ4 , first isolate it in the loop closure equations as follows: r2 cos 2 r3 sin 4 r1 r4 cos 4 r2 sin 2 r3 cos 4 r4 sin 4 r4 cos 4 r3 sin 4 r2 cos 2 r1 r4 sin 4 r3 cos 4 r2 sin 2 r3 Squaring both sides of both equations and using the identity sin cos 1 we obtain 2 r4 r3 r1 r2 2 r1 r2 cos 2 2 2 2 2 2 r2 r1 r4 Analytical Solution when θ2 is known The equation can be solved for r3, which is the one unknown. Substituting the resulting r3 value in the first closure equation, we obtain an expression with only θ3 unknown r2 cos 2 r3 sin 4 r1 r4 cos 4 r2 sin 2 r3 cos 4 r4 sin 4 r4 r3 r1 r2 2 r1 r2 cos 2 2 r2 cos 2 r3 sin 4 r1 r4 cos 4 The above expression can be solve using the previous half angle identities 2 2 2 r3 r2 r1 r4 Trigonometric Solution when θ2 is known The problem could be solved using trignonometry by solving first for the length of link O4A from the triangle O2AO4, of which two sides and an angle are known. Using length of link O4A and the triangle ABO4 the length r3 and θ4 could be found. r3 r2 r4 r1 O 4 A 2 r1 r2 2 r1 r2 cos 2 O 4 A 2 r1 r3 2 2 2 2 Analytical Solution when θ2 is known r1 r2 r3 r4 2 r2 r3 cos 2 cos 3 sin 2 sin 3 2 2 2 2 2 r1 r2 cos 1 cos 2 sin 1 sin 2 2 r1 r3 cos 1 cos 3 sin 1 sin 3 0 The expression can be seen to be the same as that obtained for a noninverted slider-crank when r1 is known with interchanging the indices 1 and 2 and the indices 3 and 4. r3 r2 r1 r4 TRANSMISSION ANGLES Analytical Solution when θ3 is known The transmission angle μ is defined as the angle between the output link and the coupler of a four-bar mechanism. It is usually taken as the absolute value of the acute angle of the pair of angles at the intersection of the two links and varies continuously as the linkage goes through its range of motion. The transmission angle is considered a measure of the quality of force transmission at the joint. A transmission angle value close to π/2 is desired, and a value of 0 or is avoided.