Beam Heating

advertisement

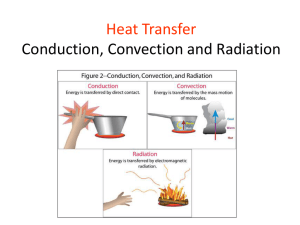

Radiopharmaceutical Production Heat transfer Beam heating Density reduction STOP Heat Transfer and Density Reduction • Heat is deposited in the target material as the beam passes through it. This heat deposition has several important consequences in terms of target design. In this section, we will look at how heat can be removed from the target and how the temperatures in the target can affect the target density and other physical characteristics Contents • • • • • • • Heat Balance Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP Heat Balance Radiopharmaceutical Production • Heat Transfer Contents Qin = Qout Heat Balance Conduction In order to have a stable radionuclide production, the heat deposited in the target must be removed. • The beam power in watts is the beam energy loss in MeV times the beam current in microamps • There are three modes of heat transfer – Conduction – Radiation – Convection Conduction is important in target bodies and foils Radiation can be important in foils and solid metal targets Convection is important inside gas and liquid targets Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP • • • Conduction Radiopharmaceutical Production Heat Transfer Contents The first form of heat transfer to be considered is conduction since in many ways it is the easiest to model. Heat applied to one side of a material will be transferred to the other side at a rate based on the thermal conductivity. Heat Balance Heat Source Conduction Radiation Convection Heat Sink Heat transfer in gas targets Qcond = -kA dT/dx Heat transfer in liquid targets where Heat transfer in solid Qcond = heat transferred by conduction (watts) targets A = cross-sectional area (cm2) k = thermal conductivity (watts/cm-°C) dT = temperature differential (°C) dx = distance differential (cm) STOP Conduction Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction In the more usual form of the equation, the heat removed is directly proportional to the thermal conductivity times the area times the temperature difference and inversely proportional to the distance the heat must travel through the substance Radiation Convection Heat transfer in gas targets Heat transfer in liquid Qcond kA(T1 T2 ) x targets Heat transfer in solid targets STOP where k = coefficient of thermal conductivity (watt/cm-°C) A = cross-sectional area (cm2) x = distance (cm) T1 = temperature of the hotter part (°C) T2 = temperature of the cooler part (°C) Conduction Example Radiopharmaceutical Production We will take an example of a target generating 600 watts of power and see how much heat can be removed through two different metal target bodies of the same thickness and size. Heat Transfer Contents Heat Balance Conduction Target Interior Metal Body Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets Beam Cooling Water kA(T1 T2 ) x If we compare aluminum with nickel for the same thickness, area and temperature differential Typical Beam 20 MeV and 30μA = 600 watts Qcond QAl =(2.37watt-cm-1°K-1)(2 cm2)(100°K)/(0.5 cm)=948 watts QNi =(0.91watt-cm-1°K-1)(2 cm2)(100°K)/(0.5 cm)=364 watts STOP It is clear that it would be possible to remove the heat through the aluminum target body, but that the nickel target would continue to heat up Radiation Radiopharmaceutical Production Heat Transfer Contents Heat Balance The next form of heat transfer is radiation. The amount of heat transferred is very dependent on the temperature of the material. The heat transferred is given by the following equation. Conduction Qrad = AσT4 Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP where Qrad = heat emitted as radiation (watts) A = area of the surface (cm2) σ = Stefan-Boltzman constant T = absolute temperature (K) Radiation Heat Loss Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP The table on the right gives the amount of heat that can be transferred at a given temperature. These calculations assume a perfect blackbody. In reality, the amount of heat being transferred must be multiplied by the emissivity which is a number less than one which represents how close the material is to a blackbody radiator. As can be seen, the amount of heat given off by this mechanism is rather low until very high temperatures are reached Temp.(°C) Temp.(°K) Qrad (watts) 100 373 0.0001 200 473 0.0023 300 573 0.0117 400 673 0.0371 500 773 0.0906 600 873 0.1878 700 973 0.3479 800 1073 0.5935 900 1173 0.9507 1000 1273 1.449 1100 1373 2.122 1200 1473 3.000 1300 1573 4.138 1400 1673 7.336 1500 1773 9.496 Convection Radiopharmaceutical Production Heat Transfer Contents Heat Balance Convection is perhaps the most difficult form of heat transfer to model accurately. Although the equation is rather simple, the value of the film coefficient is rather difficult to estimate or measure and depends on a great number of factors. Conduction Radiation Qconv = hA(T1-T2) Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid where Qconv = heat transferred by convection A = surface area (cm2) h = film coefficient (watt/cm2-K) targets T = temperature (K) STOP Radiopharmaceutical Production Convective heat transfer for laminar flow in tubes • Heat Transfer Contents Heat Balance • The key parameter in convective heat transfer is the film coefficient h which is usually tabulated in books for various geometries and materials More information can be found in texts devoted to heat transfer. Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets As an example, we can take the simple case for convective heat transfer for laminar flow of gas inside tubes. The equation describing this situation is given below. The equation look more complicated and the dimensionless quantities of Reynolds number (Re) and the Prandl modulus (Pr) are made up of combinations of more fundamental constants. Evaluation of these quantities and calculations on the heat removal are beyond the scope of this presentation. 1/ 3 hx x 1.86(Re)1/ 3 (Pr)1/ 3 k L STOP b w 0.14 Heat transfer by convection Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP • A key parameter in the efficiency of heat transfer will be whether is the flow is laminar or turbulent. Turbulent flow is much more efficient at removing heat than laminar flow. Heat Transfer in Gas Targets Heat Transfer Contents Heat Balance Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP One of the most common problems for the production of radioisotopes in gas targets is density reduction As the beam is put on target, the pressure and temperature increase as is shown in the figure. The pressure rise is correlated with the temperature rise in the target The target comes to equilibrium fairly quickly The problem has been approached in several different ways. 60 25 C4 N2/O2 Pressure Target Current 50 20 40 15 30 10 20 5 10 0 12:47 0 12:54 13:01 Time [hh:mm] 13:09 13:16 Beam current [uA] Target pressure [bar] Radiopharmaceutical Production Heat Transfer in Gas Targets Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction Radiation Convection In small volume targets, this problem is more serious The small size means that these targets must be run at high pressure where foil rupture is a distinct possibility In a typical gas target, the total length is on the order of 10 to 15 cm In order to produce carbon-11, they must be operated at about 20 atmospheres Since the volume is small, the pressure rise is large Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets 12.5 cm STOP Heat Transfer in Gas Targets Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP In the section on target physics, we learned that the beam deposits its energy in the target in the form of heat. This heat raises the temperature of the target material which in gas targets causes an increase in the pressure. The pressure with the beam on over the pressure with the bam off is called the pressure rise ratio. The pressure rise ratio reaches a maximum when there is just enough gas in the target to stop the beam as shown in the figure As the pressure increases beyond that point, the ratio falls as the heat transfer is improved Heat Transfer in Gas Targets Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction The pressure to stop the beam is dependent on both the energy and the beam current The variable is the total power deposited in the gas by the beam As shown in the figure, the higher the total power deposited in the target, the higher the pressure needed to stop the beam. Radiation Pressure to Stop the Beam Convection Heat transfer in gas 700 targets 600 Heat transfer in liquid targets Heat transfer in solid targets Pressure (psia) 500 400 5.4 MeV 10.7 MeV 14.1 MeV 300 200 100 0 0 STOP 5 10 15 Beam Current (A) 20 25 Heat Transfer in Gas Targets Radiopharmaceutical Production Heat Transfer Contents The fraction of heat transferred by convection is high except very close to the wall The fraction is relatively independent of gas temperature Heat Balance Conduction Radiation Fraction of Convection 1 Convection Heat transfer in gas 0.8 targets Heat transfer in liquid 0.6 targets Heat transfer in solid 0.4 targets Figure taken from E. Hugel PhD thesis 0.2 0 0 STOP 1 2 3 4 5 Distance from center of target 6 7 Heat Transfer in Gas Targets Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction Radiation Density Reduction is a result of target heating The heating is not uniform in the beam strike area as is shon in this photograph of the light emission from the beam in a gas target. There is spreading of the beam as well as a non-uniform distribution from the top to the bottom of the target. Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets Beam 0 1 2 Centimeters STOP Figure courtesy of S-J Heselius 3 4 5 Heat Transfer in Gas Targets Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP There are convection flow patterns set up inside the target These currents help in the convective heat transfer The temperature profile as measured in a gas target shows the nonuniform distribution and suggests the heat flow pattern as shown in the figure below. Beam Heating in Different Gases Radiopharmaceutical Production Heat Transfer Contents Heat Balance The pictures below show proton beams stopping in different gases. The different colors are due to the electronic excitation of the gas by the beam. It should also be noted that the beam areas have different shapes depending on the thermal characteristics of the gases. Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP Figure courtesy of O. Solin Liquid Targets Radiopharmaceutical Production Heat Transfer Contents • • Heat Balance Conduction • Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP • The usual method for the production of fluorine-18 used in FDG is from an irradiation of oxygen-18 enriched water with a beam of protons. The water target used for this production needs to be able to withstand high beam currents and long irradiation times of about 2 hours. If the removal of heat is inadequate, there can be boiling in the target which reduces the yield of fluorine-18 The target itself is usually just a depression cut into a block of metal or a small volume between two metal foils. Boiling in the target Radiopharmaceutical Production • Heat Transfer Contents Heat Balance Conduction • Radiation Convection Heat transfer in gas targets Heat transfer in liquid • • There is substantial density reduction in the water during irradiation if the target is boiling and if no provision has been made for this boiling in the target design. This has several consequences The yield is reduced in the target Higher pressures are created Mechanical action may affect surfaces targets Heat transfer in solid • targets • STOP At right are views of water targets with insufficient heat transfer at beam currents of 5 µA (a) and 10 µA (b) Note the increase in the intensity of the boiling at the higher beam current Beam [18O] H2O Cooling Water Radiopharmaceutical Production Heat Transfer Contents Fluorine-18 Fluoride Production • Heat Balance Conduction Radiation Convection Heat transfer in gas targets • Heat transfer in liquid targets Heat transfer in solid • targets STOP The boiling in the water can be reduced by raising the pressure on the water, effectively increasing the density In the figure, the light emission is a measure of the amount of boiling in the target. It deceases with increasing pressure as the boiling point of the water is raised. Fluorine-18 Fluoride Production Radiopharmaceutical Production Heat Transfer Contents Heat Balance Conduction Radiation Convection Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets STOP • The pressure build up in the target causes a deformation of the front window, increasing the target volume • The foil must be supported or thicker • The target shown on the bottom has a support grid to maintain the shape of the Cooling Water foil which keeps the volume Target Body constant and allows higher Foil Support pressures to be applied to the foil without rupturing. Fluorine-18 Fluoride Production Radiopharmaceutical Production Heat Transfer Contents Heat Balance • Conduction Radiation Convection • Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets Courtesy of Wake Forest STOP If the beam is too tightly focused, the beam will cause the water to boil Use a diffuse beam for water targets Fluorine-18 Fluoride Production Radiopharmaceutical Production Another Solution: Recirculate the water through the target Heat Transfer Contents Heat Balance PRESSURE /VENT Conduction Radiation COOLANT OUT Convection Heat transfer in gas TARGET BODY BEAM targets Heat transfer in liquid HEAT EXHANGERS targets Heat transfer in solid targets REGENERATIVE TURBINE PUMP COOLANT IN FILL DELIVER REGENERATIVE TURBINE PUMP RECIRCULATING TARGET SYSTEM FOR THE PRODUCTION OF F-18 AT BEAM POWER OF SEVERAL KILOWATTS STOP Heat Transfer in Solid Targets Radiopharmaceutical Production • Heat Transfer Contents Heat Balance Conduction • The main operational mode of heat transfer is conduction. Heat loss by convection and radiation are usually very small in comparison to loss by conduction. The thinner the layer between the target and the cooling water, the better the heat removal. Radiation Convection Heat transfer in gas Conductive Heat Transfer targets Radiative Heat Transfer (>500°C) Heat transfer in liquid targets Beam Heat transfer in solid targets Convective Heat Transfer Backing Plate Target Material Cooling water flow STOP Heat transfer in Thallium Target Radiopharmaceutical Production • Heat Transfer Contents Heat Balance Conduction Radiation Convection Heat transfer in gas • targets Heat transfer in liquid targets Heat transfer in solid targets • STOP The figure at right represents a Thallium Copper Copper practical situation Layer b layer c layer where there are several layers of conduction in the Incident target. 30 MeV The beam passes Proton through the thallium Cooling layer and part way Beam cc Water Flow into the copper backing plate before Vacuum losing all its energy bb aa The temperature profile for this target is given on the nest slide. ab c Heat transfer in Thallium Target Radiopharmaceutical Production Heat Transfer Contents Heat Balance Tm Conduction Radiation Thallium Copper Layer b layer Copper c layer Ti Heat transfer in gas targets Heat transfer in liquid targets Heat transfer in solid targets Temperature Convection Tb Tc Tw STOP Distance Cooling Water Return to Main Menu