MCE 571 Theory of Elasticity

advertisement

Using the Airy Stress Function approach, it was shown that the plane

elasticity formulation with zero body forces reduces to a single governing

biharmonic equation. In Cartesian coordinates it is given by

4

x

4

4

2

x y

2

4

2

y

4

0

4

and the stresses are related to the stress function by

2

x

y

2

2

, y

x

2

2

, xy

xy

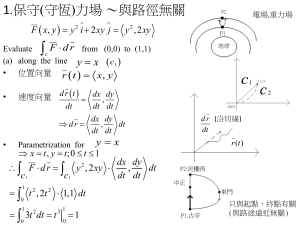

We now explore solutions to several specific problems in both

Cartesian and Polar coordinate systems

Cartesian Coordinate Solutions

Using Polynomials

In Cartesian coordinates we choose Airy stress function solution of polynomial form

( x , y )

A

m

mn

x y

n

m 0 n0

where Amn are constant coefficients to be determined. This method produces

polynomial stress distributions, and thus would not satisfy general boundary

conditions. However, we can modify such boundary conditions using Saint-Venant’s

principle and replace a non-polynomial condition with a statically equivalent loading.

This formulation is most useful for problems with rectangular domains, and is

commonly based on the inverse solution concept where we assume a polynomial

solution form and then try to find what problem it will solve.

Noted that the three lowest order terms with m + n 1 do not contribute to the

stresses and will therefore be dropped. It should be noted that second order terms

will produce a constant stress field, third-order terms will give a linear distribution of

stress, and so on for higher-order polynomials.

Terms with m + n 3 will automatically satisfy the biharmonic equation for any

choice of constants Amn. However, for higher order terms, constants Amn will have to

be related in order to have the polynomial satisfy the biharmonic equation.

Example 8.1 Uniaxial Tension of a Beam

y

T

T

2c

x

2l

Stress Field

Boundary Conditions:

Displacement Field (Plane Stress)

u

x ( l , y ) T , y ( x , c ) 0

x

xy ( l , y ) xy ( x , c ) 0

v

Since the boundary conditions specify constant

stresses on all boundaries, try a second-order

stress function of the form

A 02 y

2

x 2 A 02 , y xy 0

The first boundary condition implies that A02 = T/2,

and all other boundary conditions are identically

satisfied. Therefore the stress field solution is

given by

x T , y xy 0

y

ex

ey

u

T

1

E

1

E

( x y )

y

v

x f ( y) , v

x

2 e xy

E

( y x )

E

u

T

T

T

E

y g ( x)

E

xy

f ( y ) o y uo

g ( x) o x vo

0 f ( y ) g ( x ) 0

. . . Rigid-Body Motion

“Fixity conditions” needed to determine RBM terms

u ( 0 ,0 ) v ( 0 ,0 ) z ( 0 ,0 ) 0 f ( y ) g ( x ) 0

Example 8.2 Pure Bending of a Beam

y

M

2c

M

x

2l

Stress Field

Displacement Field (Plane Stress)

Boundary Conditions:

u

y ( x , c ) 0 , xy ( x , c ) xy ( l , y ) 0

c

c

x ( l , y ) dy 0 ,

c

c

x 6 A 03 y , y xy 0

3

Moment boundary condition implies that

A03 = -M/4c3, and all other boundary conditions

are identically satisfied. Thus the stress field is

x

3M

2c

3

v

x ( l , y ) ydy M

Expecting a linear bending stress distribution,

try second-order stress function of the form

A 03 y

x

y , y xy 0

y

u

y

3M

2 Ec

3M

2 Ec

v

x

3

3

y u

3M

2 Ec

y v

0

3M

4 Ec

3M

2 Ec

3

3

xy f ( y )

y g(x)

2

3

x f ( y ) g ( x ) 0

f ( y ) o y uo

g(x)

3M

4 Ec

x o x vo

2

3

“Fixity conditions” to determine RBM terms:

v ( l , 0 ) 0 and u ( l , 0 ) 0

u o o 0 , v o 3 Ml

2

/ 16 Ec

3

Example 8.2 Pure Bending of a Beam

Solution Comparison of Elasticity

with Elementary Mechanics of Materials

y

M

2c

M

x

I 2c / 3

3

2l

Elasticity Solution

x

u

Mxy

EI

M

I

, v

Mechanics of Materials Solution

y , y xy 0

M

8 EI

[4 y 4 x l ]

2

2

2

Uses Euler-Bernoulli beam theory to

find bending stress and deflection of

beam centerline

x

M

I

y , y xy 0

v v ( x ,0 )

M

[4 x l ]

2

2

8 EI

Two solutions are identical, with the exception of the x-displacements

Example 8.3 Bending of a Beam by

Uniform Transverse Loading

w

wl

wl

2c

x

y

2l

Stress Field

Boundary Conditions:

A 20 x A 21 x y A03 y A 23 x y

2

xy ( x , c ) 0

c

c

c

c

c

2

xy 2 A 21 x 6 A 23 xy

x

x ( l , y ) ydy 0

BC’s

3

A 23

y

5

3

y )

3

y 2 A 20 2 A 21 y 2 A 23 y

x ( l , y ) dy 0

xy ( l , y ) dy wl

2

x 6 A03 y 6 A 23 ( x y

y ( x , c ) w

3

2

y ( x, c) 0

c

2

3

2

2

3w l

2

3w

2 3

2

2 y

(

x

y

y )

3

4 c c

5

4c

3

y

w

xy

3w

2

4c

3w

y

4c

x

3w

4c

3

w

4c

3

xy

2

y

3

5

Example 8.3 Beam Problem

Stress Solution Comparison of Elasticity

with Elementary Mechanics of Materials

w

wl

wl

2c

x

y

2l

Elasticity Solution

x

w

(l x ) y

2

2

2I

w

I

(

y

3

2

c y

3

w y

2 3

2

c y c

2I 3

3

3

y

Mechanics of Materials Solution

xy

w

x(c y )

2

2

5

)

x

My

I

w

(l x ) y

2

2

2I

y 0

xy

VQ

It

w

x(c y )

2

2

2I

2I

Shear stresses are identical, while normal stresses are not

Example 8.3 Beam Problem

Normal Stress Comparisons of Elasticity

with Elementary Mechanics of Materials

x – Stress at x=0

y - Stress

l/c = 2

l/c = 3

l/c = 4

x/w - Elasticity

x/w - Strength of Materials

Maximum differences between the two theories exist

at top and bottom of beam, and actual difference in

stress values is w/5. For most beam problems where

l >> c, the bending stresses will be much greater than

w, and thus the differences between elasticity and

strength of materials will be relatively small.

y/w - Elasticity

y/w - Strength of Materials

Maximum difference between the two theories is w

and this occurs at the top of the beam. Again this

difference will be negligibly small for most beam

problems where l >> c. These results are generally true

for beam problems with other transverse loadings.

Example 8.3 Beam Problem

Normal Stress Distribution on Beam Ends

3

2

3

w y

c y 3w 1 y

1 y

x (l , y )

3

I 3

5

2 3 c

5 c

w

wl

wl

2c

x

y

2l

End stress distribution does not

vanish and is nonlinear but gives

zero resultant force.

x ( l , y ) / w

Example 8.3 Beam Problem

w

wl

wl

2c

x

y

2l

Displacement Field (Plane Stress)

w

u

[( l x

2

2 EI

v

x

3

) y x(

3

w

y

[(

2 EI

4

3

2

2c y

3

2

2y

c y

12

2

) x(

5

2

2c y

) (l x )

2

2

3

f ( y) o y uo , g ( x)

y

u

[( l x

2

2 EI

x

3

) y x(

2y

3

3

x

4

24 EI

3

5

) x(

y

w

[l (

2

4 EI

3

3

c y

2

l

2

4

2

2

3

)] f ( y )

y

4

2

c y

6

8

2

)] g ( x )

5

)c ]x o x vo

2

2

12 4 c

u o o 0 , vo

[1

( ) 2]

24 EI

5 5 2 l

5 wl

2c

4

2

3

)]

3

2

5 wl 4

12 4 c

[ ( ) c ] x

[1

( ) 2 ]

12

2

5 2

24

EI

5

5 2 l

4

(

5

4

2

2

3

2

4

2

2

w y

c y

2c y

y

y

c y

2

2

v

[( l x )

]

2 EI 12

2

3

2

6

5

x

2c

3

2

w

2

2c y

c y

2

2

Choosing Fixity Conditions u ( 0 , y ) v ( l , y ) 0

w

3

3

3

y

v ( 0 , 0 ) v max

12 4 c

[1

( ) 2]

24 EI

5 5 2 l

5 wl

4

Strength of Materials: v max

2

5 wl

4

24 EI

Good match for beams where l >> c

Cartesian Coordinate Solutions

Using Fourier Methods

A more general solution scheme for the biharmonic equation may be

found using Fourier methods. Such techniques generally use separation of

variables along with Fourier series or Fourier integrals.

4

( x , y ) X ( x )Y ( y )

x

4

Choosing X e x , Y e y

4

2

x y

2

4

2

y

4

0

i

sin x [( A C y ) sinh y ( B D y ) cosh y ]

cos x [( A C y ) sinh y ( B D y ) cosh y ]

sin y [( E G x ) sinh x ( F H x ) cosh x ]

cos y [( E G x ) sinh x ( F H x ) cosh x ]

0 0

0 C 0 C 1 x C 2 x C 3 x

2

3

0 C 4 y C 5 y C 6 y C 7 xy C 8 x y C 9 xy

2

3

2

2

Example 8.4 Beam with Sinusoidal Loading

qosinπx/l

y

qol/

qol/

2c

x

l

Stress Field

A D ( c tanh c 1)

Boundary Conditions:

x (0, y ) x (l , y ) 0

xy ( x , c ) 0

y ( x , c ) 0

y ( x , c ) q o sin( x / l )

c

c

c

c

xy ( 0 , y ) dy q o l /

xy ( l , y ) dy q o l /

B C ( c coth c 1)

sin x [( A C y ) sinh y ( B D y ) cosh y ]

x sin x [( A sinh y C ( y sinh y 2 cosh y )

2

C

B cosh y D ( y cosh y 2 sinh y )]

y sin x [( A C y ) sinh y ( B D y ) cosh y ]

2

xy cos x [( A cosh y C ( y cosh y 2 sinh y )

2

B sinh y D ( y sinh y 2 cosh y )]

l

2

c

c

c

2 2

sinh

cosh

l l

l

l

q o sinh

D

c

sinh

2

l l

2

2

c

q o sinh

c

l

c

l

l

cosh

c

l

Example 8.4 Beam Problem

qosinπx/l

y

qol/

Bending Stress

qol/

2c

x

x sin x [( A sinh y C ( y sinh y 2 cosh y )

2

B cosh y D ( y cosh y 2 sinh y )]

c

q o sinh

C

c

sinh

2

l l

2

2

l

c

cosh

l

c

l

q o cosh

, D

c

sinh

2

l l

2

2

A D ( c tanh c 1) , B C ( c coth c 1) ,

l

c

l

c

cosh

l

c

l

l

y

y

c

y

y cosh

2 l sinh

c tanh

l sinh

q

c

x

l

l

l

l

x o sinh

sin

c

c

2

l

l

c l sinh

cosh

l

l

x l/2

c

y

c coth

l cosh

l

l

l

l

c

c

c l sinh

cosh

l

l

For the case l c :

y sinh

D

3qol

2 l cosh

y

5

4c

3

y

5

, C 0 , A D , B 0

3qol y

3qol

y

y

x

x

cosh

sinh

y sin

sin

3 3

3 2

4c l

l

l

l

2c

l

3

x

2

qol

Strength

of Materials

Theory : x

My

I

2

2

sin

x

l

3

2c / 3

y

3qol

2

2c

2

3

y sin

x

l

Example 8.4 Beam Problem

qosinπx/l

y

qol/

qol/

2c

x

l

Displacement Field (Plane Stress)

u

v

cos x{ A (1 ) sinh y B (1 ) cosh y

sin x{ A (1 ) cosh y B (1 ) sinh y

E

E

C [(1 ) y sinh y 2 cosh y ]

C [(1 ) y cosh y (1 ) sinh y ]

D [(1 ) y cosh y 2 sinh y ]} o y u o

D [(1 ) y sinh y (1 ) cosh y ]} o y v o

v ( x ,0 )

D

o vo 0 , u o

u ( 0 ,0 ) v ( 0 ,0 ) v ( l ,0 ) 0

[ B (1 ) 2 C ]

E

sin x [ 2 (1 ) c tanh c ]

E

For the case l >> c

D

3q o l

5

4c

3

5

v ( x ,0 )

Strength of Materials v ( x ,0 )

3q o l

3q o l

2c E

3

4

2c E

3

4

4

sin

4

x

l

sin

x

l

[1

1 c

2

l

tanh

c

l

]

Example 8.5 Rectangular Domain with

Arbitrary Boundary Loading

y

p(x)

Must use series representation for Airy stress

function to handle general boundary loading.

b

cos

n

a

a

x [ B n cosh n y C n n y sinh n y ]

x

n 1

cos

m

y [ F m cosh m x G m m x sinh m x ] C 0 x

2

b

m 1

p(x)

x

n cos n x [ B n cosh n y C n ( n y sinh n y 2 cosh n y )]

2

n 1

2

m

cos m y [ F m cosh m x G m m x sinh m x ]

m 1

y cos n x [ B n cosh n y C n n y sinh n y ] 2 C 0

2

n

n 1

2

m

cos m y [ F m cosh m x G m ( m x sinh m x 2 cosh m x )]

m 1

xy

2

n

sin n x [ B n sinh n y C n ( n y cosh n y sinh n y )]

2

m

sin m y [ F m sinh m x G m ( m x cosh m x sinh m x )]

n 1

m 1

Boundary Conditions

x (a, y ) 0

xy ( a , y ) 0

xy ( x , b ) 0

y ( x , b ) p ( x )

Use Fourier series theory to handle general

boundary conditions, and this generates a

doubly infinite set of equations to solve for

unknown constants in stress function form.

See text for details

Polar Coordinate Formulation

Airy Stress Function Approach = (r,θ)

Airy Representation

r

1

r r

1

2

r

2

2

r

r

Biharmonic Governing Equation

2

2

2

1

1

2

2

2

r

r

r

r

4

2

1

r r

0

S

r

r

2

2

1

1

2

2

2

r

r

r

r

R

y

Traction Boundary Conditions

Tr f r ( r , ) , T f ( r , )

r

x

Polar Coordinate Formulation

Plane Elasticity Problem

Strain-Displacement

er

e

e r

u r

r

u

1

ur

r

u

u

1 1 u r

2 r

r

r

Hooke’s Law

Plane

Strain

r (er e ) 2 er

(er e ) 2 e

z (er e ) ( r )

r 2 e r , z rz 0

Plane

er

1

E

ez

e r

Stress

( r ) , e

E

( r )

1

E

1

E

1

r , e z e rz 0

( r )

(er e )

General Solutions in Polar Coordinates

Michell Solution

( r , ) f ( r ) e

2

2

1

1

2

2

2

r

r

r

r

b

4

2

f

f

1 2b

r

r

2

2

f

1 2b

r

2

3

2

2

1

1

2

2

2

r

r

r

r

b (4 b )

2

f

0

2

r

4

f 0

Choosing the case where b = in, n = integer gives the general Michell solution

a 0 a 1 log r a 2 r a 3 r log r

2

2

( a 4 a 5 log r a 6 r a 7 r log r )

2

2

( a 11 r a 12 r log r

a 13

( b11 r b12 r log r

b13

(a

r an2r

n

n1

2n

r

r

a 14 r a 15 r a 16 r log r ) cos

3

b14 r b15 r b16 r log r ) sin

3

a n3r

n

an4r

2n

) cos n

n2

(b

n2

r bn 2 r

n

n1

2n

bn 3 r

n

bn 4 r

2n

) sin n

We will use various

terms from this general

solution to solve

several plane problems

in polar coordinates

Axisymmetric Solutions

Stress Function Approach: =(r)

Navier Equation Approach: u=ur(r)er

(Plane Stress or Plane Strain)

a 0 a 1 log r a 2 r a 3 r log r

2

r 2 a 3 log r

2 a 3 log r

a1

r

2

a1

r

2

2

a3 2a2

Displacements - Plane Stress Case

2

1 du r

1

r dr

r

2

ur 0

u r C1r C 2

1

r

Gives Stress Forms

r

A

r

2

B ,

A

r

2

B , r 0

1 (1 )

a

2

(

1

)

a

r

log

r

(

1

)

a

r

2

a

(

1

)

r

1

3

3

2

E

r

A sin B cos

u

dr

3a 3 2 a 2

r 0

ur

2

d ur

4 r

E

a 3 A cos B sin Cr

•

•

Underlined terms represent

rigid-body motion

a3 term leads to multivalued behavior, and is not found following the

displacement formulation approach

Could also have an axisymmetric elasticity problem using = a4

which gives r = = 0 and r = a4/r 0, see Exercise 8-14

Example 8.6 Thick-Walled Cylinder

Under Uniform Boundary Pressure

p2

r1

p1

General Axisymmetric

Stress Solution

r

A

r

Boundary Conditions

r ( r1 ) p 1 , r ( r2 ) p 2

B

2

A

r

2

2

A

r1 r2 ( p 2 p 1 ) 1

2

ur

r

2

2

2

2

r

r [( 1 2 ) B

2

2

2

2

2

r1 p 1 r2 p 2

2

r2 r1

r2 r1

r2 r1

r1 r2 ( p 2 p 1 ) 1

1

E

2

2

r1 p 1 r2 p 2

2

r2 r1

2

r1 p 1 r2 p 2

2

2

Using Strain Displacement

Relations and Hooke’s Law

for plane strain gives the

radial displacement

2

B

2

2

r2 r1

B

r2

r

r1 r2 ( p 2 p 1 )

2

2

A

r

2

2

r2 r1

2

2

]

2 2

2

2

r1 p 1 r2 p 2

1 r1 r2 ( p 2 p 1 ) 1

(1 2 )

r

2

2

2

2

E

r2 r1

r

r2 r1

Example 8.6 Cylinder Problem Results

Internal Pressure Only

Dimensionless Stress

r1/r2 = 0.5

r1

p

r2

θ /p

r /p

r/r

2

Dimensionless Distance,

r/r2

( ) max ( r1 r2 ) /( r2 r1 ) p ( 5 / 3 ) p

2

Thin-Walled Tube Case:

t r2 r1 1

ro ( r1 r2 ) / 2

2

pr o

t

2

2

Matches with Strength

of Materials Theory

Special Cases of Example 8-6

Pressurized Hole in an Infinite Medium

p 2 0 and r2

Stress Free Hole in an Infinite Medium

Under Equal Biaxial Loading at Infinity

p 1 0 , p 2 T , r2

T

r1

p

r1

2

r p1

r1

r

2

2

r1

, p1

r

1 p 1 r1

2

ur

E

r

2

, z 0

2

2

r1

r1

r T 1 2 , T 1 2

r

r

max ( ) max ( r1 ) 2T

T

Example 8.7 Infinite Medium with a Stress

Free Hole Under Uniform Far Field Loading

Boundary Conditions

r ( a , ) r ( a , ) 0

y

a

T

r ( , )

T

( , )

T

T

x

(1 cos 2 )

2

(1 cos 2 )

2

r ( , )

T

sin 2

2

Try Stress Function

a 0 a 1 log r a 2 r a 3 r log r

2

( a 21 r a 22 r a 23 r

2

r a 3 (1 2 log r ) 2 a 2

a 3 ( 3 2 log r ) 2 a 2

r ( 2 a 21 6 a 22 r

2

6 a 23

r

4

a1

r

( 2 a 21

2

a1

r

2

6 a 23

r

4

4 a 24

r

( 2 a 21 12 a 22 r

4

2 a 24

r

2

) sin 2

2

) cos 2

6 a 23

r

4

) cos 2

4

2

2

a 24 ) cos 2

r

2

4

2

T

a T

3a

4a

1 2 1 4 2

2

r 2

r

r

2

4

T

a T

3a

1 2 1 4

2

r 2

r

r

4

2

T

3a

2a

1 4 2

2

r

r

cos 2

cos 2

sin 2

Example 8.7 Stress Results

2

4

2

T

a T

3a

4a

r 1 2 1 4 2

2

r 2

r

r

y

a

T

x

2

4

T

a T

3a

1 2 1 4

2

r 2

r

r

90

4

2

T

3a

2a

1 4 2

2

r

r

cos 2

max ( a , / 2 ) 3T

sin 2

3

120

60

2

( a , ) / T

150

30

, /T

T

cos 2

( a , ) / T

1

180

0

(

210

r

, )/T

a 2

330

240

300

270

( a , ) T (1 2 cos 2 )

( a , 0 ) T , ( a , 30 ) 0

o

r/a

Superposition of Example 8.7

Biaxial Loading Cases

T2

T1

=

+

T1

T2

Equal Biaxial Tension Case

T1 = T2 = T

2

2

r1

r1

r T 1 2 , T 1 2

r

r

max ( ) max ( r1 ) 2 T

Tension/Compression Case

T1 = T , T2 = -T

4

2

3a

4a

r T 1 4 2

r

r

4

3a

T 1 4

r

r

cos 2

cos 2

4

2

3a

2a

T 1 4 2

r

r

sin 2

( a , 0 ) ( a , ) 4 T , ( a , / 2 ) ( a ,3 / 2 ) 4 T

Review Stress Concentration Factors

Around Stress Free Holes

T

y

r1

T

a

T

T

x

K=2

K=3

T

T

T

T

T

45o

=

T

T

K=4

T

Stress Concentration Around

Stress Free Elliptical Hole – Chapter 10

Maximum Stress Field

max

x S

y

b

25

x

S t re s s C onc e nt ra tion Fa c tor

a

b

S 1 2

a

20

()max/S

15

10

5

Circular Case

0

0

1

2

3

4

5

6

7

E ccentr icity P ar ameter , b/a

8

9

10

Stress Concentration Around Stress Free

Hole in Orthotropic Material – Chapter 11

x(0,y)/S

y

S

S

Orthotropic Case Carbon/Epoxy

x

Isotropic Case

2-D Thermoelastic Stress Concentration

Problem Uniform Heat Flow Around

Stress Free Insulation Hole – Chapter 12

q

y

a

x

Stress Field

3

1 E qa a a

r

r r 3 sin

2

k

3

1 E qa a a

3 sin

r

2

k

r

3

1 E qa a a

3 cos

r

r

2

k

r

max ( a , )

E qa

sin

k

max ( a , / 2 ) E qa / k

Maximum compressive stress on hot side of hole

Maximum tensile stress on cold side / 2

/2

Steel Plate: E = 30Mpsi (200GPa) and = 6.5in/in/oF (11.7m/m/oC),

qa/k = 100oF (37.7oC), the maximum stress becomes 19.5ksi (88.2MPa)

Nonhomogeneous Stress Concentration Around Stress

Free Hole in a Plane Under Uniform Biaxial Loading

with Radial Gradation of Young’s Modulus – Chapter 14

3.5

n = 0 (homogeneous case)

n = 0.2

n = 0.4

n = 0.6

n

b/a = 20

= 0.25

b/a = 20

= 0.25

3

Stress Concentration Factor, K

n = -0.2

r

E (r ) Eo

a

2.5

homogeneous case

2

1.5

1

-0.4

-0.3

-0.2

0.1

0

-0.1

Power Law Exponent, n

0.2

0.3

0.4

Three Dimensional Stress Concentration

Problem – Chapter 13

S

Normal Stress on the x,y-plane (z = 0)

z

3

5

4 5 a

9

a

z ( r , 0 ) S 1

3

5

2(7 5 ) r

2(7 5 ) r

y

x

a

z ( a , 0 ) ( z ) max

27 15

2 (7 5 )

0 .3

S

( z ) max

2 . 04

S

S

2.2

3

S tre s s C o n c e n tra tio n Fa c to r

Normalized Stress in Loading Direction

3.5

2.5

Two Dimensional Case: (r,/2)/S

2

1.5

1

0.5

2.15

2.1

2.05

2

1.95

Three Dimensional Case: z(r,0)/S , = 0.3

1.9

0

1

2

3

4

Dimensionless Distance, r/a

5

0

0.1

0.2

0.3

P o isso n 's R a tio

0.4

0.5

Wedge Domain Problems

y

Use general stress function solution to include

terms that are bounded at origin and give

uniform stresses on the boundaries

r ( a 2 a 6 a 21 cos 2 b 21 sin 2 )

2

r 2 a 2 2 a 6 2 a 21 cos 2 2 b 21 sin 2

r

2 a 2 2 a 6 2 a 21 cos 2 2 b 21 sin 2

x

r a 6 2 b 21 cos 2 2 a 21 sin 2

Quarter Plane Example ( = 0 and = /2)

y

(r , / 2) 0

r ( r , / 2 ) S

S

r

( r ,0 ) r ( r ,0 ) 0

x

r

S

( 2 cos 2 sin 2 )

2 2

2

S

( 2 cos 2 sin 2 )

2 2

2

r

S

2

(1 cos 2

2

sin 2 )

Half-Space Examples

Uniform Normal Stress Over x 0

Boundary Conditions

( r ,0 ) r ( r ,0 ) 0

T

x

r ( r , ) 0 , ( r , ) T

Try Airy Stress Function

r

a 6 r b 21 r sin 2

2

2

2 a 6 2 b 21 sin 2

r a 6 2 b 21 cos 2

y

Use BC’s To Determine Stress Solution

r

r

T

2

T

2

T

2

(sin 2 2 )

(sin 2 2 )

(1 cos 2 )

Half-Space Under Concentrated Surface

Force System (Flamant Problem)

Y

Boundary Conditions

X

x

( r ,0 ) r ( r ,0 ) 0

r ( r , ) 0 , ( r , ) 0

r

Forces

C

X e 1 Ye 2

C

Try Airy Stress Function

( a 12 r log r a 15 r ) cos

( b12 r log r b15 r ) sin

y

Use BC’s To Determine Stress Solution

r

2

r

[ X cos Y sin ]

r 0

Flamant Solution Stress Results

Normal Force Case

2

x r cos

2

r

2Y

sin

r

r 0

or in Cartesian

components

y r sin

2

2 Yx y

( x y )

2 Yy

2

3

( x y )

2

2

xy r sin cos

Y

2

2

2

2 Yxy

2

( x y )

2

2

x

r = constant

Dimensionless Stress

y=a

xy/(Y/a)

y/(Y/a)

y

y 2Y / a

Dimensionless Distance, x/a

2

Flamant Solution Displacement Results

Normal Force Case

r

r

u r

r

ur

r

1

E

( r )

1 u

r

1 u r

r

u

r

1

E

2Y

Er

sin

( r )

u

r

1

2Y

Er

ur

sin

u

r 0

Y

E

Y

E

[( 1 )(

) cos 2 log r sin ]

2

[ (1 )(

) sin 2 log r cos (1 ) cos ]

2

Note unpleasant feature of 2-D model that

displacements become unbounded as r

0.1

Y

0

On Free Surface y = 0

u r ( r ,0 ) u r ( r , )

Y

(1 )

2E

Y

u ( r ,0 ) u ( r , )

[( 1 ) 2 log r ]

E

-0.1

-0.2

-0.3

-0.4

-0.5

-0.6

-0.5

0

0.5

Comparison of Flamant Results with

3-D Theory - Boussinesq’s Problem

Cartesian Solution

P

x

u

1 2

Py z

1 2

P

z

2

, v

2

, w

4 R R

R z

4 R R

R z

4 R

Px

x

y

z

Free Surface Displacements

u z ( R ,0 )

y

z

P (1 )

P

2 R

E

[(1 ) 2 log r ]

3-D Solution eliminates the

unbounded far-field behavior

2 R

2

P

2 R

2

3 Pz

3

2 R

5

2

3x 2 z

z

R

x (2 R z )

(1 2 )

3

2

R

R

z

R

R

(

R

z

)

2

3y 2z

z

R

y (2 R z )

(1 2 )

3

2

R z

R ( R z )

R

R

, xy

yz

P

2 R

3 Pyz

2 R

2

3 xyz

(1 2 )( 2 R z ) xy

3

2

R(R z)

R

2

5

, xz

2

3 Pxz

2 R

5

Cylindrical Solution

Corresponding 2-D Results

u ( r ,0 )

P

2

z

2 (1 ) 2

R

(1 2 ) r

rz

ur

2

4 R R

R z

r

2

z

uz

2 (1 ) 2

4 R

R

P

P

u 0

P

2 R

2

3 r 2 z (1 2 ) R

3

R z

R

(1 2 ) P z

R

2

R z

2 R

R

z

3 Pz

3

2 R

5

, rz

3 P rz

2 R

2

5

Half-Space Under Uniform Normal

Loading Over –a x a

p

x

2

a 1

a

x r cos

2Y

y r sin

2Y

2

2

sin cos

2

r

r

sin

xy r sin cos

y

dx

r

d

x

2p

y

2p

xy

2p

2

1

2

1

2

1

dY = pdx = prd /sin

cos d

2

sin

2

d

p

2

p

2

sin cos d

3

2Y

r

sin

2

cos

d x

2p

d y

2p

d xy

2p

cos

2

d

sin

2

d

sin cos d

[ 2 ( 2 1 ) (sin 2 2 sin 2 1 )]

[ 2 ( 2 1 ) (sin 2 2 sin 2 1 )]

p

2

[cos 2 2 cos 2 1 ]

Half-Space Under Uniform Normal

Loading - Results

0.5

Dimensionless Stress

xy /p

y/p

Dimensionless Maximum Shear Stress

0.45

0.4

Concentrated Loading

max/(Y/a)

0.35

0.3

0.25

Distributed Loading

max/p

0.2

0.15

0.1

0.05

0

Dimensionless Distance, x/a

max - Contours

0

1

2

3

4

5

6

7

Dimensionless Distance, y / a

8

9

10

Generalized Superposition Method

Half-Space Loading Problems

p(s)

x

a

a

t(s)

y

x

2y

y

2y

xy

2y

p ( s )( x s )

a

[( x s ) y ]

3

a

2

a

a

2

2

2

2

p(s)

[( x s ) y ]

2

2

ds

p ( s )( x s )

a

[( x s ) y ]

2

2

ds

2

a

2

2

2

s

a

t ( s )( x s )

a

[( x s ) y ]

2y

2

2

2y

a

a

3

2

2

ds

t ( s )( x s )

[( x s ) y ]

2

2

a

t ( s )( x s )

a

[( x s ) y ]

2

2

2

2

2

ds

ds

Photoelastic Contact Stress Fields

(Point Loading)

(Uniform Loading)

(Flat Punch Loading)

(Cylinder Contact Loading)

Notch/Crack Problem

y

r

x

Stress Free Faces

= 2 -

Try Stress Function: r [ A sin B cos C sin( 2 ) D cos( 2 ) ]

( 1) r

2

[ A sin B cos C sin( 2 ) D cos( 2 ) ]

r ( 1) r

2

[ A cos B sin C ( 2 ) cos( 2 ) D ( 2 ) sin( 2 ) ]

Boundary Conditions: ( r , 0 ) r ( r , 0 ) ( r , 2 ) r ( r , 2 ) 0

sin 2 ( 1) 0

At Crack Tip r 0:

n

1 , n 0 , 1, 2 ,

2

Stress O ( r

2

) , Displaceme

nt O ( r

1

)

Finite Displacements and Singular Stresses at Crack Tip 1< <2 = 3/2

Notch/Crack Problem Results

y

r

r

x

Stress Free Faces

= 2 -

5

3

3

3 1

5 sin ) B (cos cos )

A (sin

2

3

2

2

2

4 r

3

3

3 1

3 sin ) B (cos cos )

A (sin

2

2

2

2

4 r

r

1

3

3

3 1

sin )

A (cos cos ) B (sin

2

3

2

2

2

4 r

r

Transform to Variable

r

•

•

•

•

3 A

2

2

cos

r

( 3 cos )

sin

2

B

sin

(1 cos )

3B

sin

B

2 r

(1 3 cos )

(1 cos )

2

2 r

(1 cos )

2

2 r

2

r

3 A

2

r

3 A

2

cos

cos

(1 3 cos )

2

Note special singular behavior of stress field O(1/r)

A and B coefficients are related to stress intensity factors and are useful in fracture

mechanics theory

A terms give symmetric stress fields – Opening or Mode I behavior

B terms give antisymmetric stress fields – Shearing or Mode II behavior

Crack Problem Results

Contours of Maximum Shear Stress

Mode I (Maximum shear stress contours)

Mode II (Maximum shear stress contours)

Experimental Photoelastic Isochromatics

Courtesy of URI Dynamic Photomechanics Laboratory

Mode III Crack Problem – Exercise 8-32

y

z

r

Contours for Mode III Crack Problem

●

x

Anti-Plane Strain Case

u v 0 , w w( x, y )

w

2

w

2

w A r sin

r

2

2

1 w

r r

, z

1 w

2

A

2 r

Stresses Again

r

2

cos

2

O r

2

0

, zr

1 / 2

A

2 r

sin

2

z - Stress Contours

Curved Beam Under End Moments

Dimensionless Stress, a /M

b

2

r

a

M

M

r ( a ) r (b ) 0

r ( a ) r ( b ) 0

b

a

b

a

dr 0

rdr M

a 0 a 1 log r a 2 r a 3 r log r

2

r

4M

4M

r 0

2

[

a b

N

N

r

2

log(

2

b

) b log(

2

a

2

[

a b

r

2

b/a = 4

Theory of Elasticity

Strength of Materials

2

log(

2

r

) a log(

2

b

b

a

) b log(

2

a

Dimensionless Distance, r/a

)]

r

r

b

) a log(

2

a

r

)b a ]

2

2

Curved Cantilever Beam

P

r

a

b

r (a , ) r (b, ) 0

Dimensionless Stress, a/P

= /2 b/a = 4

Theory of Elasticity

Strength of Materials

r ( a , ) r ( b , ) 0

b

a

b

a

b

a

b

a

b

a

r ( r , 0 ) dr P

Dimensionless Distance, r/a

b

( r , 0 ) dr ( r , 0 ) rdr 0

a

( r , / 2 ) dr P

( r , / 2 ) rdr P ( a b ) / 2

r ( r , / 2 ) dr 0

( Ar

3

B

r

Cr Dr log r ) sin

r

P

2

(r

a b

2

r

P

a b

( 3r

r

r

P

N

2

) sin

2

) sin

r

a b

r

a b

2

3

2

(r

2

r

2

N

2

3

N

a b

3

2

a b

2

r

2

) cos

Disk Under Diametrical Compression

P

D

=

P

Flamant Solution (1)

+

+

Flamant Solution (2)

Radial Tension Solution (3)

Disk Problem – Superposition of Stresses

y

P

(1 )

x

2P

r1

(1 )

(1 )

x

(2)

2P

r1

y

xy

(2)

x

(3)

3

x

cos 1 sin 1

2P

r2

2P

r2

2P

r2

y

r1

cos 1

r1

(2)

1

2P

y

xy

cos 1 sin 1

2

(3)

2

2

cos 2 sin 2

r2

2

P

cos 2

3

x

cos 2 sin 2

2

2P

D

, xy 0

2

2

2P (R y)x

(R y)x

1

4

4

r1

r2

D

y

3

3

2P (R y)

(R y)

1

4

4

r1

r2

D

xy

2

2

2P (R y) x (R y) x

4

4

r1

r2

( 3)

r1 , 2

x (R y)

2

2

Disk Problem – Results

y

P

1

x-axis (y = 0)

r1

x

2

r2

2

2

2P D 4x

x ( x ,0 )

2

2

D D 4 x

y-axis (x = 0)

2

x (0, y )

4

2P

4D

y ( x ,0 )

1

2

2 2

D ( D 4 x )

xy ( x , 0 ) 0

2P

D

y (0, y )

Constant

2P

2

2

1

D 2y D 2y D

xy ( 0 , y ) 0

P

(Theoretical max Contours)

(Photoelastic Contours)

(Courtesy of URI Dynamic Photomechanics Lab)

Applications to Granular Media Modeling

Contact Load Transfer Between Idealized Grains

P

P

P

P

Four-Contact Grain

(Courtesy of URI Dynamic Photomechanics Lab)