3D Printer CDR

advertisement

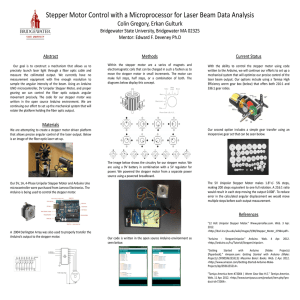

Meron Reda (Project Manager) Brian Calinaya (System Engineer) Lennon Nguyen (Power Train) Moheb Youssef (3D Printing) Peter Flores (Manufacturing Division Manager and Controls) Changed the Extruder Carriage to account for melting point limitations. Old PLA carriage had melting point of 185° C. New ABS has melting of 230° C. Have the best print quality possible Use parts that are ubiquitous Reduce and minimize chance of backlash ◦ However some backlash may be present to prevent jamming, allow for lubrication, etc. We chose a smaller pulley to increase resolution and to fit with the new belt To fit the smaller pulley, we made the Y-Axis motor attachment thinner Design an air scrubber that eliminates all toxic fumes and smells. Must adhere to Sasha’s dimensions and allows flexibility. We chose 27x24x20 inches. The cost must not exceed $200. Currently testing the box for dead zones and temperature concerns. Testing with ABS plastic and adjusting the filter tubing size accordingly Retractable floor tray that the 3D printer sits on in the box for easy access. Add light sources in the box (Color LEDs)! We have completed the Ramps Board section of building the new 3D Printer and are currently working on the exoskeleton. We are currently at the exoskeleton stage of our build process. After, we will be working on the hotends and x-bars. A "subtractive" method for processing raw material with a drill-like rotating cutter through a set of computer-driven movements of the cutting head. Benefits: Fast, high accuracy, efficient Design a CNC machine using a Dremel or similar rotary type tool head and FoldaRap structural base made of aluminum and printed PLA plastic brackets. LEVEL 1 Complete CNC design Portable Uses printable parts Compact ◦ 335 x 348 x 318 mm LWH +21mm for handle Cost Effective ◦ Under $600 Durable ◦ Aluminum structural support LEVEL 2 Counter resistance of different types of materials during operation Dremel tool head is used for subtractive method Stepper motors to move axes in place of belts and pulleys; less resistive Unlike other CNC designs that use wood for the structure, we chose to use the Foldarap as the outer frame since it is made out of extruded plastic, which we can print, and aluminum which is sturdy and durable. This design would be efficient because the aluminum can hold up for years. Using stepper motors to drive up the axes would be less resistive and last longer. Printing the hinges and brackets saves us money. We based our CNC design on both the Prusa Mendel and the Foldarap 3D printer Assemble the Foldarap Base as seen in build instructions manual Can also find instructional videos online X-Axis: Assemble as seen in the Foldarap Build Manual except instead of 2 smooth rods, use 1 smooth rod and 1 threaded rod. Attach a stepper motor to one side with the shaft facing horizontal. The stepper motor will be driving the threaded rod. Assemble Y-Axis, with two smooth rods and one threaded rod in the middle to drive the printed plate. A stepper motor will be attached to the threaded rod. Z-Axis: Assemble as seen in the Foldarap Build Manual. Add stepper motors to the top of the zaxis screw drives. We will be attaching a Dremel in place of the extruder carriage, enclosed in a printed holder, similar to the one shown in the picture. Multi-speed from 5K to 35K RPM Quieter than other models Inexpensive at around $80 Lightweight: 18.8 oz Equipped with multiple attachments for the changing out the tool head Use ReplicatorG (http://replicat.org/) to convert gcode or stl file Use RAMPS board version 1.4, as in the Prusa Mendel, to control the stepper motors that are controlling the x, y, and z axes. Use Marlin Firmware Arduino Mega 2560 This board is the brain of our CNC machine and serves as the main interface to the computer. The Arduino board is programmed with a modified Reprap Gcode interpreter and the 3 axes motion. RAMPS Shield RAMPS is a shield board that needs to be connected to an Arduino MEGA 1280 or 2560 board. The Image shows a RAMPS board mounted on a Arduino MEGA board with four Pololu stepper motor controller boards installed End Stop (Limit Switch) The switch and little debounce circuit is, at minimum mounted at one end of each axis. Provide a home location for the machine. Qty. Product Description Product Number/SKU RAMPS RepRap Arduino Mega Pololu Shield 1 electronics 1 AVR ARDUINO MEGA2560 REV 3 3 x Mechanical Endstop 3D printer, reprap, prusa, 1 mendel, makerbot 6 6mm Diameter x 300mm Length Smooth rod 2 6mm Diameter Threaded rod 1 meter 4 NEMA17 stepper motors Printed Parts for structure 5 20x20 beam 6mm slot 1 meter 1 Dremel 4000 A000067 Source http://www.ebay.com/it m/RAMPS-RepRapArduino-Mega-PololuShield-electronicsassd-Pololus-kit-PCB/261105171806 http://www.mouser.co m/ProductDetail/Arduin o/A000067/?qs=gMoq Xxk%2F%2F5apEOlL63o O8Q%3D%3D&gclid=CL uhwKu2yrMCFWlxQgodi 2UA7g http://www.ebay.com/it m/3-x-MechanicalEndstop-3D-printerreprap-prusa-mendelmakerbot/150922395345?pt=LH _DefaultDomain_2&has h=item2323acfed1 Salvaged from old printers/scanners http://www.screwfasten ers.co.uk/threadedrods-0/stainless-steel0/threaded-rod-a2stainless-steel-din975-0/tige-filetee-m6inox-a2-din-975.html Ebay 3D Printed http://www.aluminiumprofile.co.uk/acatalog/ Aluminium_Profile_with _6mm_Slot.html#aKJN_ 20992_20888 Amazon Unit Price Total Price $7.40 $7.40 $38.95 $38.95 $14.90 $14.90 $0.00 $0.00 $3.72 $10.00 $0.00 $7.44 $40.00 $0.00 $4.60 $79.00 $23.00 $79.00 $210.69 To get better efficiency and avoid calculating the resistance of each printed material, look into switching a Dremel tool head with a laser cutter. Qty. Product Number/SKU Source 1 OPTIX 18 in. x 24 in. x .093 in. Acrylic Sheet 241610 Home Depot $9.78 $9.78 2 OPTIX 11 in. x 14 in. x .093 in. Acrylic Sheet 241302 Home Depot $4.24 $9.48 1/2 in. x 2 ft. x 4 ft. Medium Density 2 Fiberboard Handy Panel 279388 Home Depot $8.97 $17.94 22078553622 Home Depot $1.83 $1.83 201426 Home Depot $11.48 $11.48 1 92 mm fan N/A Scrap parts N/A 0 2 80 mm fan N/A Scrap parts N/A 0 N/A 3D Printed N/A 0 http://store.trinitylabs.com LM-GT2PB /gt2-pulley-belt-set/ $30.00 $30.00 N/A 0 Product Description Unit Price Total Price Air Scrubber 1 Liquid Nails Projects 10 oz. 1 GE Carbon Replace Filter 2-Pack Filter printed parts Resolution Upgrade 1 GT2 Pulley & Belt Set Extruder Carriage Upgrade 1 New Printed Extruder Carriage N/A 3D Printed $80.51