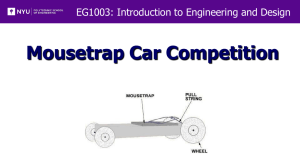

Mousetrap Car Construction

advertisement

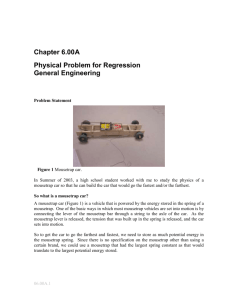

Mousetrap powered car that is quick and cheap to build but performs well. Design by Bill Kuhl http://www.scienceguy.org Copyright 2010 For a “College for Kids” summer class I wanted to design a simpler mousetrap car than the 3-wheeled bamboo mousetrap cars I had been experimenting with. In designing the Quicky Mouse mousetrap car I had the following objectives: •Fast to build so it could be built in one hour class time. •Cheap to build with easy to find parts. •Good performance, this car should do well in distance competition. •Adjustable steering, the steering can be adjusted to track straight. This was my first prototype which was 2 inches longer. On a very smooth surface it would travel a long distance very slowly. If the surface was less than perfect, it might stop. Like with many things, higher performance can have a trade off in reliability. These are tools that would be good to have for this project. Two types of saws are shown, only one is needed. The needle nose pliers could be used for wire cutting also. The line I used is a Spectra fishing line, it is very thin, strong and does not stretch much. One 150 yard spool can be used for a lot of mousetrap cars. Use the smaller cable ties, I had trouble with the line catching on the cable tie with a larger one. The small screw eyes I used were from two manufacturers and were slightly different sizes but both worked well. Bundled in packages of 14 which will be good for 3 ½ mousetrap cars. Coat hanger wire is used for axles. Try to find a coat hanger that has straight sections of wire. Sometimes solutions will appear in front of you in unusual places. I wanted a rubbery material for the wheel hub that would grip the axle and I spotted this tarp strap in my garage. Squares can be cut from the cord material easily with a scissors. CD ROMS can usually be found from free sources. If you can not find a tarp strap, no doubt other rubbery materials will work. The coat hanger wire axle fits tightly into the rubber and no glue is needed. Eraser material should work also but it is heavier. What is a “Lever Arm”? The term “lever arm” is used many times in this article so a little explanation is in order. The lever arm connects to the mousetrap spring and the opposite end is attached to the line. It pulls the string that is wrapped around the axle. For best performance it should be light but it also needs to be strong and stiff. Types of Wood Used – balsa sheet 3/16” or ¼” thick is cut into strips 1” wide. Hardwood 3/8” x 3/8” is cut into ¾” lengths. Oak square or dowel ¼” wide can be used for a strong lever arm. Finding the Materials in the Stores I thought it might be helpful to point with pictures to exactly where you might find the materials to make the Quicky Mouse mousetrap car. Most of the materials will be found in a hardware store or lumber supply store. Balsa wood will be found in a hobby shop. The fishing line will be found where ever fishing tackle is sold. I attempted to give further clues where the items might be found within the store. Cable ties should be found in the electrical department of a hardware or lumber supply store. Screw eyes should be found near other types of connectors in the hardware section of a hardware or lumber supply store. The screw eyes needed for this project will no doubt be the smallest size you will find. Round and square dowels can often be found in a rack where building supplies are sold. Mousetraps are normally found near gardening-type merchandise along with other types of pest control products. Victor mousetraps are normally sold in packages of two mousetraps. The $.97 price is the cheapest I have seen so far. Fishing Tackle There are many types of fishing line sold, but do not use the plastic-type. The best one to use is Kevlar braided fishing line. Tarp straps can be found in the automotive section, some stores only sell the cloth-covered bungee cords which is not what you want. This rack was found in an Ace Hardware store. Found in a Hobby Shop Balsa and basswood are normally found in a display case like this one in a hobby shop. Putting all the parts that would fit in re-sealable bags worked very well for a group build. Using a single-edge razor blade or a hobby knife cut 1” wide strips using a straightedge. The razor saw works well for cutting the 1” wide balsa strips to length. You will need two strips 14” long and four strips 3 ½” long. Balsa strips needed for frame of mousetrap car. This small saw worked well for cutting the ¾” long blocks from the 3/8” x 3/8” hardwood, four blocks are needed. The razor blade appears to cut plastic sections used for wheel spacers better than using a scissors. A scissors will work but can split the plastic at times. Four spacers ¾” long have been cut from a plastic drinking straw. The tarp strap cuts rather easily with a good scissors. Four wheel hubs cut from tarp strap material. Preparing the Mousetrap I use Victor mousetraps which are often specified in mousetrap car competition rules. Many of the parts of the mousetrap are not needed or are used in another part of the project so the following steps will show how to modify the mousetrap. A needle nose pliers works well for taking parts off the mousetrap. Put one half of the pliers under the loop and lift the handle of the pliers upwards. Keep the wire with loop at the end of it for use later on the car. This is the last part to pry off the mousetrap. Cut the wire on the left side just before the 90 degree bend. Cut the other end of the left-over piece of wire to remove the short bent section. This piece of wire is glued to lever arm and line is tied through the loop. Find a straight section of the coat hanger and cut with wire cutters. I cut the axles 6 inches long which is plenty long but better too long than too short, two axles needed per car. The construction starts by building a rectangle from the two long lengths of balsa and two of the short lengths. If you are using hot glue, be sure to spread it out to cover entire joint and push the pieces firmly together. Hold the pieces together until the hot glue has cooled enough to start to set. Make sure the pieces are at 90 degree angles. Pretty good looking joint, only a small amount of excess glue. Glue the other long piece to the first end piece. Glue the other end piece. On the end where the mousetrap is placed, a short piece of balsa goes on top at the very end. Another short piece of balsa goes on top to support the other end of the mousetrap. Mark on the long pieces where the short piece should be glued based on the mousetrap location. Make sure the mousetrap is positioned the correct way, the arm part needs to be in line with the center of the mousetrap car. Glue the mousetrap to the two balsa support pieces. Glue has been spread at the proper location, place the balsa piece down quickly before the glue starts to harden. Mark on the two balsa mousetrap support pieces the left edge of where the mousetrap will be glued. Glue the mousetrap to the support pieces. Hot glue the small wood blocks at the edges in front and in the rear. It might be easier to mark the position for the screw eye holes before gluing but you can mark afterwards also. I marked out a cross on the blocks and then used a push pin to start a small hole. The pink foam was used to cover the sharp end of the push pin when not in use. Push pin has started one hole, it will be easier to screw in the screw eye now. Make the holes are as straight as possible. The screw eye has been screwed in place. Do not screw it in entirely, then you can adjust the angle of the axle slightly. Two screw eyes in place and turned vertical so the axle will go through. By the 90 degree angle mark I had drawn below, it can be seen that the axle is not in perfect alignment. Adjust the screw eyes to get the axle in alignment so the car runs straight. That is better! Axle is straight now and the car should run straighter. With wheels that can be removed, this adjustment can be done again if your car does not track straight. Glue the tarp strap material to the CD ROM so that it covers the hole with an even amount covering the edges of the hole. CA (super glue) works but no doubt other glues will work too. Mark the center of the wheel and drill through the tarp strap rubber with a 1/16” drill bit. Make the hole as straight as possible. Drill bit has gone all the way through the soft rubber material. Plastic straw spacers go to outside of screw eyes and wheels are carefully pressed on to the axles until there is a slight gap between rubber hub and plastic spacer. Assembling the Lever Arm There are many materials and methods for building the lever arm. Because of breakage problems with balsa lever arms, I used ¼” square oak strip that I found at a lumber retailer on my last car. The brass tube would not be needed when balsa is not used for lever arm, just glue to mousetrap wire and spring, then wrap with string. On my 3-wheel bamboo car I used two bamboo skewers glued together. The lever arm attaches to mousetrap wire with glue and wrapping with string. The brass was glued to the balsa lever arm, the balsa tended to break just beyond where the brass tube ended. A rigid but light weight lever arm can be constructed from strips of 1/8” balsa wood glued to form a T-shape. If you decide to use the balsa lever arm, I would suggest gluing 1/8” brass tube to balsa for the mousetrap connection. A needle nose pliers is good for placing the lever side of the spring in place over the lever arm. The spring Must be attached to the lever arm. Attaching the Cable Tie to Rear Axle Cable tie is attached to the rear axle. Pull the cable tie tight. Clip off the extra plastic from the cable tie, a scissor will work for this but wire cutters works better. Put a drop of glue on the cable tie so it will not slip on the axle. I carefully used hot glue to fasten the cable tie on this car and it seems to be holding. Too much hot glue and the loop in the line might catch and not come off. Tying Knots – (Not About Marriage) There needs to be a loop tied in one end of a length of fish line and the other end is tied to the end of the lever arm. Tie the loop first and then tie to the lever arm and it will be easier to adjust the length. The line needs to be almost touching the rear axle but not touching the axle and certainly not longer than the axle. Tying a loop knot that will not slip is not difficult but the line is very thin making it slightly difficult to handle. Bend one end into a loop, create a circle with the two sides of the loop and tuck the end of the loop through the circle. Pull the knot tight and trim off some of the extra. The loop should come close to, but not reach the axle. If the line is longer it will not come off the axle at the end of the lever arm stroke. Adjust the length of the line here when you tie it to the end of the lever arm. A square knot will work here. The extra piece of wire from the mousetrap was glued to end of lever arm. Winding the Line Up – Running Your Mousetrap Car Carefully pull the loop forward and hook it around the box part of the cable tie. It helps to lift the lever arm up slightly first before pulling the line. Lift the lever arm up slightly before pulling the loop over the cable tie. Wind the string around the axle, if you leave the axles long it is easy to get your fingers around the axle to wind the line. Turn the axle clockwise. Let the mousetrap car go, it will run best on a very smooth surface indoors. Be sure to check out my general information article about mousetrap cars and of course my website: http://www.scienceguy.org