PICARSO_Seminar - University of Adelaide

advertisement

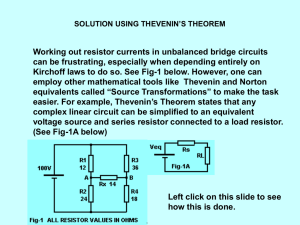

Hardware System Process Painting System Project Outcomes Design Problems Testing and Results Image Processing Future Work Design Specifications Control Software 1028:PICARSO Sven Paschburg 2 PICARSO: Cable-driven robot Process standard image formats Reproduce images on vertical surface Image Processing 1028:PICARSO Control Software Hardware Sven Paschburg Painting System 3 Image Output Original Processed Painted End-Effector 1028:PICARSO Sven Paschburg 4 MATLAB Motor 3 Image Processing Toolbox Motor 2 RS232 Cables Cables Vertical Wall End-Effector (Mathworks 2010) Graphical User Interface Design Environment Motor 1 (GUIDE) 1028:PICARSO Sven Paschburg 5 Hardware Design Problem Painting System Project Outcomes Design Specifications Testing and Results Image Processing Future Work System Architecture Control Software 1028:PICARSO Samuel Oosterholt 6 Goals: Develop mechanical system Scalable work space size Up to 3×3m Manipulate and stabilise the end-effector Mounting the system: in operation and in testing 1028:PICARSO Samuel Oosterholt 7 Hektor (Franke & Lehni 2002) Viktor (Lehni & Rich 2008) Four actuators Two actuators Image producing robots ‘X’ ‘V’ Configuration Scalable workspace sizeon gravity Relies Cable driven Hektor’s actuator configuration 1028:PICARSO PICARSO’s actuator configuration Samuel Oosterholt Viktor’s actuator configuration 8 Full System Three motors ‘Y’ configuration Cables Upper motors control position Lower stabilises Reduces cost Render of PICARSO system 1028:PICARSO Samuel Oosterholt 9 Motor Mount Base Plate Motor Motor Controller Spooling System Cable feeding system 1028:PICARSO Samuel Oosterholt 10 Motor Mount Motors parallel to painting surface Plate mounts to painting surface Double spool and bearing Two cables Reduce yaw and pitch Minimise kickback 1028:PICARSO Samuel Oosterholt 11 Motor Mount 180° Reorientated by Cables: eyebolts and (Braid Spiderwire fishing line) pulleys Ø = 0.30mm Tmax = 13.6kg Can move pulleys Small elasticity and eyebolts Proximity to canvas Stability 10m of cable 7×7m workspace Lower mount uses fairleadsattach to Cables 180° sweep turnbuckles 1028:PICARSO Samuel Oosterholt 12 Hardware selected from Maxon Motors Numerous operation modes Modular components Discounted cost & support 250W EC45 Motors and Maxon EPOS2 70/10 Motor Controller 1028:PICARSO Samuel Oosterholt 13 Not feasible Canvas implemented to wall mount for testing Simulate 3.6 × 3.2msurface easel (working area: 2.8 × 2.8m) Reduces ripple in wind environment Constrained by testing PICARSO’s easel in the Vibrations Laboratory PICARSO’s easel in the FSAE shed PICARSO’s canvas 1028:PICARSO Samuel Oosterholt 14 Hardware Design Problem Painting System Project Outcomes Design Specifications Testing and Results Image Processing Future Work System Architecture Control Software 1028:PICARSO Neil Yeoh 15 Goals: Design an appropriate painting system which: 1028:PICARSO Produces circular patterns (< 3cm) Is fast (> 1Hz) and light (< 3kg) Does not cause instabilities Houses suitable paint capacity Is reliable, durable, and repeatable Neil Yeoh 16 Three types of painting mechanisms *1 *2 Airbrush Spray Can *3 Spray Gun Circular Patterns ( <3cm) Fast ( >1Hz) Light ( <3kg) No Instabilities Paint Capacity Reliable Durable Repeatable ** Image references at end of slides 1028:PICARSO Neil Yeoh 17 Electrical Air Compressor Automatic Pressure-fed Spray Gun Paint Line Air Regulator Compressed Air Line *7 Personal Computer *5 *4 Air Line Paint Regulator Solenoid Pressurised Paint Canister *8 Electrical Signal *9 *6 ** Image references at end of slides 1028:PICARSO Neil Yeoh 18 Anest Iwata SGA-101 Automatic Pressure-fed Spray Gun Pattern Adjust Knob Fluid Adjust Knob Air Line Fitting Knob Nozzle Paint Line 1028:PICARSO Neil Yeoh 19 Testing procedure Ideal Settings identified: Specification Setting Air Pressure 2.0 bar Paint Pressure 0.5 – 1.0 bar Spray Distance 5 – 10 cm Fluid Adjust Knob Half Turn Spray Duration 0.2 – 1.0 s Repeatability Spray Duration Results: Consistent < 3cm black circles 1028:PICARSO Neil Yeoh 20 1028:PICARSO Neil Yeoh 21 Large Sleeve Sleeve Shaft Bearing Spacer Small Sleeve Eyebolts Bearings Spray Gun 1028:PICARSO Neil Yeoh 22 1028:PICARSO Neil Yeoh 23 Hardware Design Problem Painting System Project Outcomes Design Specifications System Architecture Testing and Results Image Processing Future Work Control Software 1028:PICARSO Ian Hooi 24 Goals: Develop image processing software to: Transform input image to user specified settings Reproduce input image in binary form Output in Raster (pixel-by-pixel) form Extension Goal: Output in Vector (line) form 1028:PICARSO Ian Hooi 25 1. 2. 3. 4. Input image Resized to appropriate resolution Stretching and refitting Greyscale form Scaled from 0-1 where 0 is black, 1 is white Original 1028:PICARSO Resized Ian Hooi Greyscale 26 Fill Images: Direct conversion from greyscale binary Edge Images: outlines of the image Edge Image Fill Image 1028:PICARSO Ian Hooi 27 Converted to binary form Threshold filter 1028:PICARSO Original Binary: Threshold = 0.25 Binary: Threshold = 0.5 Binary: Threshold = 0.75 Ian Hooi 28 Raster: pixel by pixel approach Vector: line based approach Raster Based Output Vector Based Output Optimal 70 70 70 65 65 60 60 60 55 55 50 50 50 45 45 40 40 40 35 35 30 30 30 25 25 20 20 20 10 1028:PICARSO 20 30 40 50 60 Ian Hooi 10 10 20 20 30 30 40 40 50 50 60 60 29 Image output in binary form 1 represents white 0 represents black Read and processed by Control Software Slow to paint 70 60 50 40 30 20 1 1 1 0 1 0 1 0 1 1 1 0 1 1 1 1 0 1 1 1 0 0 0 1 0 0 0 1 1 10 0 20 30 Optimal 40 = 50 60 70 65 60 55 50 45 40 35 30 25 20 10 20 30 40 50 60 1028:PICARSO Ian Hooi 30 Aim: Raster Vector Searching Algorithm based on Portrayer (Benedettelli 2008) and Erik’s XY Plotter (2007) Adjacent pixels chains Control software Optimal 70 60 50 40 = 30 20 10 20 10 20 30 40 50 60 70 65 60 55 50 45 40 35 30 25 20 30 1028:PICARSO 40 50 60 Ian Hooi 31 Hardware Design Problem Painting System Project Outcomes Design Specifications Testing and Results Image Processing Future Work System Architecture Control Software 1028:PICARSO Joyce Phan 32 Goals: Software for Raster Mode Convert Image Processing output to: • Control motors • Control spray gun Extension Goals: Software for Vector Mode Graphical User Interface (GUI) 1028:PICARSO Joyce Phan 33 Image Processing Output 1 0 0 1 Control Software Positioning Commands x y Cartesian Co-ordinates Inverse Kinematics L1 , L 2 , L 3 Cable Lengths turns Output Commands 1028:PICARSO Joyce Phan on off Motor Turn Units Motor Commands Spray Gun Commands 34 0 1 1 1 0 1 0 1 0 1 1 1 0 1 1 1 1 0 1 1 1 0 0 0 1 0 0 0 1 1 Image Processing Output 1028:PICARSO Raster Mode Joyce Phan Vector Mode 35 1028:PICARSO Joyce Phan 36 Motor Controller 3 Slave Motor Controller 2 Slave Solenoid RS232 PC Master RS232 RS232 Digital Output • Instructions from Master to Slaves via 3 Parallel RS232 links • Outputs controlled in Maxon RS232 Communication Protocol Motor Controller 1 Slave 1028:PICARSO Joyce Phan 37 Position Mode Motor 3 Position Mode Motor 2 • Position Mode • Driven in steps • Current Mode • Provides tension • Minimises instabilities Motor 1 Current Mode 1028:PICARSO Joyce Phan 38 • Easy access to user settings during operation 1028:PICARSO Joyce Phan 39 Hardware Design Problem Painting System Testing and Results Design Specifications Image Processing Project Outcomes Future Work System Architecture Control Software 1028:PICARSO Sven Paschburg 40 Goals: Scaled system – µAngelo Full scale system – PICARSO Image processing software Control software Graphical User Interface (GUI) Extension Goals: Vector-based painting Touch screen interface 1028:PICARSO Sven Paschburg 41 Scaled System - µAngelo Kinematics test bed Tri-motor Y-configuration proof of concept Front view picture of µAngelo 1028:PICARSO Oblique angle picture of µAngelo Sven Paschburg Picture of µAngelo’s end-effector 42 Full Scale System - PICARSO Raster painting functionality Scalable across a vertical surface • Up to 3×3m workspace area Complete a picture in 1 hour Test Metrics Accuracy & Precision Pixel Size Reliability Stability Workspace Resolution Speed 1028:PICARSO Sven Paschburg 43 Raster Painting Functionality 10 mm 100 mm 1028:PICARSO 50 mm Specifications Achievement Accuracy ± 10 mm Precision ± 5 mm Workspace Resolution 10 – 100 mm Workspace Resolution (ideal) 10 – 25 mm 25 mm Sven Paschburg 44 Raster Painting Functionality Parameter Achievement Pixel Size (min.) 8 mm Pixel Size (ideal) 10 mm 0.2 s 0.25 s 0.5 s 1.0 s 8 mm 10 mm 16 mm 20 mm 1028:PICARSO Sven Paschburg 45 Raster Painting Functionality Specifications Achievement Stability ± 25 mm (z – axis) z pitch roll yaw Bottom view of the end-effector Side view of the end-effector 1028:PICARSO Sven Paschburg 46 Scalable across a vertical surface Specifications Achievement Workspace Area 0.5 × 0.5 m to 7.0 × 7.0 m A picture showing the ability of the end-effector to move around the workspace 1028:PICARSO Sven Paschburg 47 Goals: Scaled system – µAngelo Full scale system – PICARSO Image processing software Control software Graphical User Interface (GUI) Oblique angle picture of painted µAngelo‘fills’ image A 1.8 × 1.8m of the Mona Lisa 1028:PICARSO Sven Paschburg 48 Extension Goals: Analog communication Complete a picture in 1 hour Vector-based painting Touch screen interface Future years: Colour painting Wireless communication Commercial product 1028:PICARSO Sven Paschburg 49 1028:PICARSO Sven Paschburg 50 Benedettelli, D. 2008, NXT Portrayer Robot, viewed 11th April 2010 <http://robotics.benedettelli.com/portrayer.h tm> Convict Episcopal de Luxembourg, 2007, Erik’s XY-Plotter, viewed 11th April 2010, <http://www.convict.lu/Jeunes/ultimate_stuf f/Erik_s_xx_plotter/E_xy_plotter.htm>. Franke, U & Lehni, J 2002, Hektor, viewed 29 December 2009, <http://www.hektor.ch/Book/Hektor.pdf/>. 1028:PICARSO Sven Paschburg 51 1. 2. 3. 4. 5. 6. 7. 8. 9. Spray can - http://comps.fotosearch.com/comp/UNN/UNN113/spraycan_~u14072509.jpg Airbrush http://imgs.tootoo.com/e1/00/e10006f419523aa3bb036a77fb5038dd.jpg Spray gun - http://image.made-in-china.com/2f0j00DaTQeBfgIEMJ/HVLPSpray-Gun-RP8021-2S-H827-S-.jpg Air Compressor - http://toolmonger.com/wpcontent/uploads/2006/05/aircompressor.jpg Festo Air Regulator - http://www.festo.com/rep/nlbe_be/assets/LR_2008_1314u.jpg Pressurised Paint Canister http://www.smitsgroup.co.nz/images/objectimages/PT2-Paint-Tank.jpg Festo Solenoid Valve http://www.luconda.com/artikeldetails/27/29/xx/bilder/2093457-1-Festo-CPE18M1H-3GL-1-4.jpg Iwata Spray Gun - http://www.anestiwata.co.jp/english/products/paint/prd/fog/auto/images/ceramic_ph01.jpg Personal Computer - http://www.ubergizmo.com/photos/2008/12/dell-xps-13.jpg 1028:PICARSO Sven Paschburg 52 53 PICARSO Mechanical & Electrical Hardware 1028:PICARSO Software Painting System Image Processing Samuel Oosterholt Control Software 54 1028:PICARSO Sven Paschburg 55 1028:PICARSO Joyce Phan 56 1028:PICARSO Joyce Phan 57 1028:PICARSO Joyce Phan 58 1028:PICARSO Ian Hooi 59 PC Master EPOS2 Slave (Node 1) EPOS2 Slave (Node 2) NI PCI-6221 card NI SB 68-LP (Analogue Inputs) Breakout Board 1028:PICARSO Joyce Phan EPOS2 Slave (Node 3) 60 1028:PICARSO Joyce Phan 61 1028:PICARSO Joyce Phan 62 1028:PICARSO Joyce Phan 63 1028:PICARSO Sven Paschburg 64 1028:PICARSO Sven Paschburg 65 1028:PICARSO Sven Paschburg 66 1028:PICARSO Sven Paschburg 67 Image Processing Software Raster processing functionality Process an image in less than 60s Vector processing functionality Processing Settings Options Image Input JPEG, PNG, GIF, BMP, TIFF Image Resolution 10 – 500 pixels Image Threshold 0–1 Conversion Type Fills, Edges Palette Type Binary (Black & White) Sizing Square, Original Aspect Ratio Image Processing Time <3s 1028:PICARSO Sven Paschburg 68 High Level Control Software Raster functionality Human Machine Interface (HMI) Vector functionality Touch screen interface Specifications Options Control Mode Raster Painting, Vector Painting, Manual Positioning, Spray Control Platform Mathworks MATLAB 2007 + Operating System Windows XP, Vista, 7 Interface Type Graphical (Touch Screen) 1028:PICARSO Sven Paschburg 69 Low Level Control Software Position the motors Control the motor velocity and acceleration Read back the current position Actuate the spray gun solenoid Specifications Options Control Functions Position Control, Set Max. Velocity & Acceleration, Read Current Position, Activate Digital Output Platform Mathworks MATLAB 2007 + Operating System Windows XP, Vista, 7 Positioning Accuracy (theoretical) 2.11 × 10-3 mm 1028:PICARSO Sven Paschburg 70 Complete a picture in 1 hour A 1.8 × 1.8m painted ‘fills’ image of the Mona Lisa 1028:PICARSO Parameter Specification Speed 2 – 250 mms-1 Acceleration 2 – 150 mms-2 Picture Time (av.) 2.5 hrs (edge image) A 1 × 1m painted ‘edge’ image of the University of Adelaide logo Sven Paschburg 71