Document

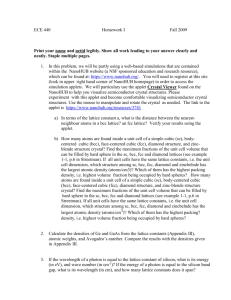

advertisement

Chapter 5

Structure of

Solids

6 Lectures

1

Solids

Crystalline

Long-range periodicity

Gives sharp

diffraction patterns

Has sharp melting point

Has higher density

Noncrystalline

No long-range periodicity

Does not give sharp

diffraction patterns

Does not have a sharp

meliing point

Has a lower density

2

3

Factors promoting the formation of noncrystalline

structures

1. Primary bonds do not extend in all three

directions and the secondary bonds are not

strong enough.

2. The difference in the free energy of the

crystalline and non crystalline phases is

small.

3. The rate of cooling from the liquid state is

higher than a critical cooling rate.

Metallic Glass: 106 K s-1

4

Inorganic Solids

Covalent Solids

Metals and Alloys

Ionic Solids

Silica: crystalline and amorphous

Polymers

Classification

Structure

Crystallinity

Mechanical Behaviour

5

7th. Group (Halogens): single covalent bonds

Diatomic molecules

Weak van der Waals bond between molecules

F2, Cl2: Gas; Br2: Liquid;

I2: orthorhombic xl

6

6th. Group: two covalent bonds: long zig-zag chains

Weak van der Waals bonds between chains

mostly noncrystalline

7

5th. Group: Three covalent bonds: Puckered sheets

Weak van der Waals bond between sheets

Mostly noncrystalline

8

4th. Group: Carbon

9

Allotropes of C

Graphite

Buckminster Fullerene

1985

Diamond

Carbon Nanotubes

1991

Graphene

2004 10

Graphite

Sp2 hybridization 3 covalent bonds

Hexagonal sheets

a = 2 d cos 30°

= √3 d

y

x

a

=120

b=a

d = 1.42 Å

a = 2.46 Å

11

Graphite

a = 2.46 Å

c = 6.70 Å

Lattice: Simple Hexagonal

Motif: 4 carbon atoms

A

x

B

y

A

www.scifun.ed.ac.uk/

12

c

Graphite

Highly Anisotropic:

Properties are very different in the a and c directio

Uses:

Solid lubricant

Pencils (clay + graphite, hardness

depends on fraction of clay)

carbon fibre

www.sciencemuseum.org.uk/

13

Diamond

Sp3 hybridization 4 covalent bonds

Tetrahedral bonding

Location of atoms:

8 Corners

6 face centres

4 one on each of the 4 body diagonals

14

Diamond Cubic Crystal: yLattice1 & motif?

0,1

M

S

P

N

D

A

T

B

3

4

Q

L

K

D

y

R

C

1

2

R

M

S

A

0,1

C

1

4

L

Q

T

0,1

1

4

x

0,1

2

K

3

4

1

2

N

B

P

1

2

0,1

x

Projection of the unit cell on

the bottom face of the cube

Diamond Cubic Crystal

= FCC lattice + motif: 000; ¼¼¼

15

Crystal Structure = Lattice + Motif

Diamond Cubic

Crystal Structure

=

FCC

Lattice

+

2 atom

Motif

000

1 1 1

4 4 4

There are only three Bravais Lattices: SC, BCC, FCC.

Diamond Cubic

Lattice

16

There is no

diamond

cubic

lattice.

17

Diamond Cubic

Structure

Coordination 4

number

Corners

Face

Inside

1

1

8 6 1 4 8

Effective number of atoms in the unit cell =

8

2

Relaton between lattice parameter

and atomic radius

3a

2r

4

8r

a

3

Packing efficiency

4 3

8 r

3

3

0.34 18

3

a

16

Diamond Cubic Crystal Structures

C

Si

Ge

Gray Sn

a (Å) 3.57 5.43 5.65 6.46

19

Equiatomic binary AB compounds having

diamond cubic

y

1

2

0,1

0,1

like structure

IV-IV compound: SiC

III-V compound:

AlP, AlAs, AlSb,

GaP, GaAs, GaSb,

InP, InAs, InSb

1

4

3

4

1

2

S

1

2

0,1

1

4

1

2

3

4

II-VI compound:

ZnO, ZnS,

CdS, CdSe, CdTe

I-VII compound:

CuCl, AgI

0,1

0,1

20

USES:

Diamond

Abrasive in polishing and grinding

wire drawing dies

Si, Ge, compounds:

semiconducting devices

SiC

abrasives, heating elements of furnaces

21

Inorganic Solids

Covalent Solids

Metals and Alloys

Ionic Solids

Silica: crystalline and amorphous

Polymers

Classification

Structure

Crystallinity

Mechanical Behaviour

22

Metals and Alloys

1. Metallic bond: Nondrectional (Fact)

As many bonds as geometrically possible (to

lower the energy)

Close packing

2. Atoms as hard sphere (Assumption)

3. Elements (identical atoms)

1, 2 & 3 Elemental metal crystals:

close packing of equal hard spheres

23

Close packing of equal hard spheres

Arrangement of equal nonoverlapping spheres

to fill space as densely as possible

Sphere packing problem:

What is the densest packing of spheres in 3D?

Kepler’s conjecture, 1611

P.E

3 2

0.74

Kissing Number Problem

What is the maximum number of spheres that

can touch a given sphere?

Coding Theory

Internet data transmission

24

Close packing of equal hard spheres

1-D packing

A chain of spheres

occupiedlength

P.E.=

=1

total length

Kissing Number= 2

Close-packed direction of atoms

25

Close packing of equal hard spheres

2-D packing

A hexagonal layer of atoms

Close-packed directions?

Close-packed plane of atoms

3

occupiedarea .907

P.E.=

total area

2 3

Kissing Number=6

1940 L. Fejes Toth : Densest packing of circles in plane

26

Close packing of equal hard spheres

3-D packing

First layer A

A

A

C

C

A

B

A

A

A

B

B

A

B

C

C

Third layer A or C

A

C

C

B

Second layer B

B

A

A

A

C

C

B

B

A

A

A

C

B

A

A

Close packed crystals:

…ABABAB… Hexagonal close packed (HCP)

…ABCABC… Cubic close packed (CCP)

27

Geometrical properties of ABAB stacking

A

C

B

a

b=a

A

=120

C

A

B

B

C

B

A

A

A

c

B

A

C

B

B

A

B

C

A

C

C

A

C

A

A

A

B

A

B

A

A

C

B

A

A

A and B do not have identical neighbours

Either A or B as lattice points, not both

Unit cell: a rhombus based prism with a=bc; ==90, =120

The unit cell contains only one lattice point (simple) but two atoms (motif)

ABAB stacking = HCP crystal = Hexagonal P lattice + 2 atom motif 000

28

2/3 1/3 1/2

c/a ratio of an ideal HCP crystal

A

A

C

C

B

B

C

B

A

B

A

C

B

A

c

C

A

B

A

B

C

A

B

C

A

C

A

A

A

B

A

A

A

C

B

A

B

A

A

A single B atom sitting on a base of three A atoms forms a regular

tetrahedron with edge length a = 2R

The same B atom also forms an inverted tetrahedron with three A atoms

sitting above it

c = 2 height of a tetrahedron of edge length a

2 2

c

a

3

29

Geometrical properties of ABCABC stacking

C

A

A

C

C

A

B

A

A

A

A

B

B

B

B

C

C

C

3 a

A

C

C

B

A

B

A

A

A

A

C

C

B

B

B

A

A

A

C

B

A

A

All atoms are equivalent and their centres form

a lattice

Motif: single atom 000

ABCABC stacking

= CCP crystal

= FCC lattice + single atom motif 000

30

Geometrical properties of ABCABC stacking

C

B

A

C

3 a

B

A

All atoms are equivalent and their centres form

a lattice

Motif: single atom 000

ABCABC stacking

= CCP crystal

= FCC lattice + single atom motif 000

31

Geometrical properties of ABCABC stacking

C

A

A

C

C

A

B

A

A

A

A

B

B

B

B

C

C

C

3 a

A

C

C

B

A

B

A

A

A

A

C

C

B

B

B

A

A

A

C

B

A

A

All atoms are equivalent and their centres form

a lattice

Motif: single atom 000

ABCABC stacking

= CCP crystal

= FCC lattice + single atom motif 000

32

Close packed planes in the FCC unit cell of cubic close

packed crystal

Body

diagonal

A

B

C

A

Close packed planes: {1 1 1}

33

Stacking sequence?

ABA: HCP

34

35

Find the mistake in the following picture:

http://www.tiem.utk.edu/~gross/bioed/webmodules/s

pherefig1.gif

36

Table 5.1

Coordination Number and Packing Efficiency

Crystal

Structure

Coordination

number

Packing

efficiency

Diamond cubic (DC)

4

0.34

Simple cubic (SC)

6

0.52

Body-centred cubic

8

0.68

Face-centred cubic

12

0.74

37

Voids in Close-Packed Crystals

TETRAHEDRAL VOID

OCTAHEDRAL VOID

B

A

A

A

B

C

A

A

B

A

No. of atoms defining

the void

4

No. of voids per atom

2

Edge length of void

2R

Size of the void

0.225 R

B

A

A

6

A

Experiment 2

1

2R

HW

0.414 R

38

Location of Voids in FCC Unit cell

39

Solid Solution

A single crystalline phase consisting of two or more elements is

called a solid solution.

Substitutional Solid solution

of Cu and Zn (FCC)

Interstitial solid solution of

C in Fe (BCC)

40

Hume-Rothery Rules for Extensive

Solid Solution (Unlimited solubility)

Interstitial solid solution

Substitutional solid solution

1. Structure factor

Crystal structure of the two elements should be

the same

2. Size factor:

Size of the two elements should not differ

by more than 15%

3. Electronegativity factor:

Electronegativity difference between the elements

should be small

4. Valency factor:

Valency of the two elements should be the same

41

TABLE 5.2

System

Crystal

structure

Radius of

atoms, Ǻ

Valency

Electronegativity

Ag-Cu

Ag

Au

FCC

FCC

1.44

1.44

1

1

1.9

1.9

Cu-Ni

Cu

Ni

FCC

FCC

1.28

1.25

1

2

1.9

1.8

Ge-Si

Ge

Si

DC

DC

1.22

1.18

4

4

1.8

1.8

All three systems exhibit complete solid solubility.

42

BRASS

Cu

FCC

+

Zn

HCP

Unfavourable structure factor

Limited Solubility:

Max solubility of Cu in Zn: 1 wt% Cu

Max Solubility of Zn in Cu: 35 wt% Zn

43

Ordered and Random

Substitutional solid solution

Random Solid

Solution

Ordered Solid

Solution

44

Ordered and random substitutional solid

solution

β-Brass: (50 at% Zn, 50 at% Cu)

Disordered solid solution of β-Brass:

Above

470˚C

470˚C

Below

470˚C

Corner and centre both have

50% probability of being

occupied by Cu or Zn

Ordered solid solution of β-Brass:

Corners are always occupied

by Cu, centres always by Zn

45

Intermediate Structures

Crystal structure of Cu:

FCC

Crystal structure of Zn:

HCP

Crystal structure of

random β-brass:

BCC

Such phases that have a crystal structure different

from either of the two components are called

INTERMEDIATE STRUCURES

If an intermediate structure occurs only at a fixed

composition it is called an INTERMETALLIC

COMPOUND, e.g. Fe3C in steels.

46

IONIC SOLIDS

Cation radius: R+

Anion radius: RUsually

R R

1. Cation and anion attract each other.

2. Cation and anion spheres touch each other

3. Ionic bonds are non-directional

1, 2, 3 => Close packing of unequal spheres

47

IONIC SOLIDS

Local packing geometry

1. Anions and cations considered as hard spheres

always touch each other.

2. Anions generally will not touch, but may be close

enough to be in contact with each other in a

limiting situation.

3. As many anions as possible surround a central cation

for the maximum reduction in electrostatic

energy.

48

Effect of radius ratio

Rc

0.155

Ra

unstable

Anions not touching

the central cation,

Anions touching each

other

Rc

0.155

Ra

Rc

0.155

Ra

Critically stable

stable

Anions touching

the central

cation

Anions touching

Rc

0.155 Ligancy 2

Ra

Anions touching

central cation

Anions not touching

each other

Rc

0.155 Ligancy 3

Ra

49

Rc

0.155 Ligancy 3

Ra

However, when

Rc

0.225

Ra

tetrahedral coordination

with ligancy 4 becomes stable

Recall tetrahedral void in close-packed

structure.

Thus

Rc

0.155

0.225 Ligancy 3

Ra

50

Table 5.3

Ligancy as a Function of Radius Ration

Ligancy

Range of radius ratio

2

0.0 ― 0.155

3

0.155 ― 0.225

Triangular

4

0.225 ― 0.414

Tetrahedral

6

0.414 ― 0.732

Octahedral

8

0.732 ― 1.0

Cubic

12

1.0

Configuration

Linear

FCC or HCP

51

Example 1:

NaCl

RNa

RCl

0.54

0.414 0.54 0.732

Ligancy6

OctahedralCoordination

cae2k.com

NaCl structure =FCC lattice + 2 atom motif: Cl- 0 0 0

Na ½ 0 0

52

NaCl structure

continued

CCP of Cl─ with Na+ in ALL octahedral voids

2RNa" 2RCl a

53

Example 2 : CsCl Structure

RCs

RCl

0.91

0.732 0.91 1

Ligancy 8

Cubic coordination of Claround Cs+

seas.upenn.edu

CsCl structure = SC lattice + 2 atom motif: Cl 000

Cs ½ ½ ½

BCC

2RCs 2RCl 3a

54

Example 3: CaF2 (Fluorite or fluorospar)

RCa 2

RF

0.73

0.73 0.732

Octahedral or cubic

coordination

Actually cubic coordination

of F─ around Ca2+

But the ratio of number of F─ to Ca2+ is 2:1

So only alternate cubes of F─ are filled with Ca2+

55

Simple cubic crystal of F─ with Ca2+ in alternate cube centres

Alternately, Ca2+ at

FCC sites with F─ in

ALL tetrahedral voids

CaF structure= FCC lattice + 3 atom motif

Ca2+

F─

F─

000

¼¼¼

-¼ -¼ -¼

56

Example 4: ZnS (Zinc blende or sphalerite)

RZn 2

RS 2

0.48

0.414 0.48 0.732

Ligancy6

OctahedralCoordination

However, actual ligancy is 4

(TETRAHEDRAL

COORDINATION)

wikipedia

Explanation: nature of bond is more covalent than ionic

57

ZnS structure

CCP of S2─ with Zn2+ in alternate tetrahedral voids

seas.upenn.edu

ZnS structure = FCC lattice + 2 atom motif

S2─ 0 0 0

Zn2+ ¼ ¼ ¼

58

59

pixdaus.com

60

theoasisxpress

61

What is common to

1, glass of the window

2. sand of the beach, and

3. quartz of the watch?

62

pixdaus.com

Structure of SiO2

Bond is 50% ionic and 50 % covalent

RSi 4

RO 2

0.29

0.225 0.29 .414

Tetrahedral coordination of

O2─ around Si4+

Silicate

tetrahedron

63

Silicate tetrahedron electrically

unbalanced

4─

2─

4+

2─

2─

2─

O2─ need to be shared between two tetrahedra

64

1. O2─ need to be shared between two tetrahedra.

2. Si need to be as far apart as possible

Face sharing

Edge sharing

Corner sharing

Silicate tetrahedra share corners

65

2D representation of 3D periodically repeating pattern of

tetrahedra in crystalline SiO2. Note that alternate tetrahedra

66

are inverted

2 D representation of 3D random network of silicate

tetrahedra in the fused silica glass

67

Network Modification by addition of Soda

Na

+ Na2O =

Na

Modification leads to breaking of primary bonds between

silicate tetrahedra.

68

2 D representation of 3D random network of silicate

tetrahedra in the fused silica glass

69

5.7 Structure of Long Chain

Polymers 109.5

H

Degree of

Polymerization:

No. of repeating

monomers in a chain

H

C

A

C

C

70

Freedom of rotation about each bond in space

leads to different conformations of C-C

backbone

109.5

71

72

5.8 Crystallinity in long chain polymers

Fig. 5.17: semicrystalline polymer

73

Factors affecting crystallinity of a long chain

polymer

1. Higher the degree of polymerization lower is

the degree of crystallization.

Longer chains get easily entagled

74

Branching

2. More is the branching less is the tendency to

crystallize

75

Tacticity

3. Isotactic and syndiotactic polymers can

crystallize but atactic cannot.

76

Copoymers: polymeric analog of solid

solutions

4. Block and random copolymers promote non

crystallinity.

77

Plasticizers

Low molecular weight additives

Impedes chains coming together

Reduces crystallization

78

Elastomer

Polymers with very extensive elastic deformation

Stress-strain relationship is non-linear

Example: Rubber

79

Liquid

natural

rubber

(latex)

being

collected

from the

rubber

tree

80

Isoprene molecule

commons.wikimedia.org

H H3C H

C=C-C=C

HH

H

81

H

H

CH3 H

H

Isoprene

molecule

CH3 H

CCCC

H

H

CCCC

H

H

H

Polymerization

Polyisoprene

mer

Liquid

(Latex)

82

Vulcanisation

H

H

CH3 H

CCCC

H

H

+ 2S

H

H

CCCC

H H CH H

Weak

van der

Waals

bond

3

83

Vulcanisation

H

H

CH3 H

CCCC

H

H

S S

H

H

Crosslinks

CCCC

H H CH H

3

84

Effect of cross-linking on polyisoprene

Natural

rubber

Elastomer

Ebonite

liquid

Elastic

solid

Hard &

brittle

not

x-linked

lightly

x-linked

heavily

x-linked

85

Charles Goodyear

December 29, 1800-July 1, 1860

Debt at the time of

death $200,000

Life should not be estimated

exclusively by the standard of dollars

and cents. I am not disposed to

complain that I have planted and

others have gathered the fruits. One

has cause to regret only when he

sows and no one reaps.

86

Another interesting property of

elastomers

Thermal behaviour

87

Elastomer sample

under tension

Elastomer

sample

heat

Tensile force

Coiled chains

Higher

entropy

straight

chains

Lower

entropy

Contracts on

heating

Still

lower

entropy

F

88

Elastomers have ve thermal

expansion coefficient, i.e., they

CONTRACT on heating!!

EXPERIMENT 4

Section 10.3 of the textbook

89

N 0 kT

F

L0

F

N0

k

T

L0

L

L L0

L0 L

2

applied tensile force

number of cross-links

Boltzmann constant

absolute temperature

initial length (without F)

final length (with F)

90

Bond stretching in straightened

out molecules

Experimental

Theory: Chain uncoiling

N kT

F 0

L0

L L0 2

L0 L

91