PowerPoint

advertisement

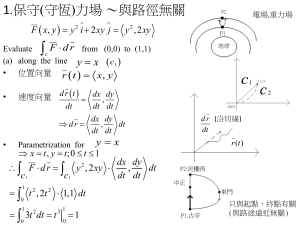

Dynamic Simulation: Constraint Equations Objective The objective of this module is to develop the equations for ground, revolute, prismatic, and motion constraints for a planar mechanism. These equations will be developed for a piston-crank assembly in a Boxer style engine. These constraint equations will be used in the next Module (Module 4) to show how position, velocity, and accelerations are computed. Although the equations developed for this module are for a planar (2D) mechanism, the methods can be generalized to 3D mechanisms. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Boxer Style Engine Module 3 – Constraint Equations Page 2 Boxer style engines have a horizontally opposed piston configuration. This has several advantages Lower center of gravity Lower vertical height Lighter weight Less vibration Boxer style engines are used by Porsche and Subaru. Because of their low vertical profile they are often called pancake engines. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Cross Section View Module 3 – Constraint Equations Page 3 This module will use the piston-crank portion of this engine to demonstrate how kinematic and motion constraints are developed. Counterweight Cylinder Liner Bottom Bearing Cap Piston Connecting Pin Piston Rod Bearing Piston Pin © 2011 Autodesk Rod Bolt Crank Shaft Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. Crank Bearing www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Planar System Module 3 – Constraint Equations Page 4 The boxer engine rotating assembly contains four piston assemblies. Constraint equations will be written for one piston assembly to demonstrate the process. This single assembly can be represented as a planar mechanism. A Dynamic Simulation of the complete system will be presented in another module. © 2011 Autodesk Cylinder 1 Cylinder 2 Cylinder 3 Cylinder 4 The planar equations will be developed for Cylinder 3. Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Global Coordinate System Module 3 – Constraint Equations Page 5 The constraint equations will be referenced to the stationary coordinate system shown in the figure. This reference coordinate system is called the global coordinate system. Capital letters are used to indicate that a coordinate or vector refers to this coordinate system. Lower case letters will be used to indicate a coordinate or vector is referred to a body fixed coordinate system associated with a part. Z © 2011 Autodesk X Cylinder 3 Y X Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Part ID’s Module 3 – Constraint Equations Page 6 The process of developing the constraint equations is facilitated by identifying each component by a letter. The five components shown with letters make up the basic system for which the constraint equations will be written. A Cylinder Liner E Crank Bearing (Not Visible) B Piston C Connecting Rod D Crank Shaft © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Mobility Module 3 – Constraint Equations Page 7 Gruebler’s equation can be used to establish the mobility of the planar mechanism. A Cylinder Liner E Bodies (B) = 5 Grounded bodies (G) = 2 Revolute joints (R) = 3 Prismatic joints (P) = 1 Crank Bearing (Not Visible) Mobility DOF 3( B) 2( R) 2( P) 3(G ) 3(5) 2(3) 2(1) 3(2) 1 A mobility of one will require one motion constraint. © 2011 Autodesk B Piston C Connecting Rod Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. D Crank Shaft www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation List of DOF’s Module 3 – Constraint Equations Page 8 The DOF’s are associated with a set of generalized coordinates. Each body has 3 DOF and 3 generalized coordinates. The generalized coordinates for the planar mechanism are listed on the right. Fifteen constraint equations must be developed that will enable each of the fifteen generalized coordinates to be determined. © 2011 Autodesk X cgA List of Generalized Coordinates YcgA A X cgB Format X-coordinate of the cg of Body A Body X A cg Capital letter Center of indicates that variable is associated Gravity with the global coordinate system. Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity YcgB B X cgC YcgC C X cgD YcgD D X cgE YcgE E Education Community Section 4 – Dynamic Simulation Ground Joints Module 3 – Constraint Equations Page 9 The cylinder liners are pressed into the engine block and do not move. The pistons move relative to the cylinder liners and the combination make a prismatic joint. Cylinder 1 Cylinder 2 Cylinder 3 The cylinder liners must be mathematically grounded or fixed in space. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. Cylinder 4 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Cylinder Liner Ground Equations Module 3 – Constraint Equations Page 10 The location of the center of gravity and the orientation of the principal axes of inertia are shown in the figures. y x The ground constraint equations that fix the position of the c.g. and orientation of the principal axes can be written as y z X cgA156.8 mm 0 Y cgA 0 cgA 0 © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Crank Bearing Ground Joint Module 3 – Constraint Equations Page 11 The crank bearing is fixed in the engine block and does not move. The crank shaft rotation relative to the crank bearing can be represented by a revolute joint. All of the parts in the planar system must lie in the global X-Y plane. Therefore, a “virtual” crank bearing will be placed at the origin of the global coordinate system so that the planar equations can be developed. Virtual Crank Bearing Located at the Origin Y Z X Crank Bearing Constraint Equations X E cg 0 YcgE 0 cgE 0 © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Summary of Ground Joint Equations Module 3 – Constraint Equations Page 12 Cylinder Liner Virtual Crank Bearing X cgA156.8 m m 0 X cgE 0 Y cgA 0 YcgE 0 cgA 0 0 E cg Each of these equations fix one DOF for the respective part in space. None of the equations are a function of time. None of the equations involve more than one part. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 2D Coordinate Transformation Matrix Module 3 – Constraint Equations Page 13 In subsequent slides it will be necessary to transform the components of a vector from a body fixed coordinate system to the global coordinate system. This transformation is accomplished with the transformation matrix [T()]. From the figure, y cos θ X x cos y sin Y x sin y cos © 2011 Autodesk Y y sin θ θ x x sin θ y θ x cos θ X Matrix Form X cos Y sin cos T sin Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. sin x y cos y sin y cos www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Revolute Joint Module 3 – Constraint Equations Page 14 There are three revolute joints in the piston-crank assembly Between the piston and connecting rod Between the connecting rod and crankshaft Between the crankshaft and crank bearing The constraint equations for a revolute joint will be developed using the two bodies shown in the figure. Body A and B have the same translational motion at the joint but can have relative rotation. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. yB Body B Y Body A B yA xB xA Joint A X Two bodies connected at a common point that allows relative rotational motion. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Revolute Joint Module 3 – Constraint Equations Page 15 The position of Joint 1 on Body A relative to the global coordinate system is given by the equation A A A R1 Rcg r1 Y Joint 1 yA Body A ˆj 1 r1 A xA iˆ A A The components of Rcg are written with respect to the global coordinate system base vectors and the A r components of 1 are written with respect to the body fixed coordinate system. © 2011 Autodesk Jˆ Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. A Rcg Iˆ cg RA X A r1 x1Aiˆ y1A ˆj A Rcg X cgA Iˆ YcgA Jˆ www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Revolute Joint Module 3 – Constraint Equations Page 16 The components of the body fixed position vector must be transformed to the global coordinate system before the components of the two vectors can be added. This is accomplished using the transformation matrix introduced earlier. © 2011 Autodesk Position Vector Equation A A A R1 Rcg r1 Component Form X 1A X cgA cos A A A A Y Y sin 1 cg Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. sin A x1A A A cos x1 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Revolute Joint Module 3 – Constraint Equations Page 17 The coordinates of Joint 1 on Body A are X 1A X cgA cos A A A A Y Y sin cg 1 sin A x1A cos A y1A In a Revolute Joint the coordinates of the joint must be same for each body. Thus, X 1A X 1B A B Y1 Y1 Similarly, the coordinates of Joint 1 on Body B are X X cos B Y Y sin B 1 B 1 B cg B cg B sin cos B B x y B 1 B 1 General Form of the Constraint Equations for a Planar Revolute Joint © 2011 Autodesk or X cgA cos A A Ycg sin A X cgB cos B B Ycg sin B Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. sin A x1A cos A y1A sin B x1B 0 B B cos y1 0 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Revolute Joint Module 3 – Constraint Equations Page 18 The general form of the constraint equations for a planar revolute joint is X cgA cos A A Ycg sin A X cgB cos B B Ycg sin B Joint 1 sin A x1A cos A y1A sin B x1B 0 B B cos y1 0 The specific equations for the three revolute joints in the piston-crank mechanism will now be developed 2nd Revolute Joint Joint 2 Joint 3 © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 1st Revolute Joint Module 3 – Constraint Equations Page 19 Piston Body B The location of the joint relative to the c.g. is needed to B define the parameters x1 & y1B For the piston, 28 mm y x 28mm B 1 x y 0 B 1 C.G. Joint 1 © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 1st Revolute Joint Module 3 – Constraint Equations Page 20 The location of the joint relative to the c.g. is needed to C define the parameters x1 & y1C From the picture, x1C 102.6mm Connecting Rod Body C 102.6 y1C 0 y x Joint 1 © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 1st Revolute Joint Module 3 – Constraint Equations Page 21 Using the geometry from the piston and connecting rod, the revolute joint constraint equation becomes x1B 28m m x1C 102.6mm y1B 0 y1C 0 Joint 1 X cgB cos B B Ycg sin B X cgC cos C C Ycg sin C © 2011 Autodesk sin x1B cos B y1B B sin C x1C 0 C C cos y1 0 1st Revolute Joint Constraint Equations X cgB 28 cos B X cgC 102.6 sin C 0 YcgB 28 sin B YcgC 102.6 cos C 0 Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 2nd Revolute Joint Module 3 – Constraint Equations Page 22 General Form of Constraint Equation X cgC cos C C Ycg sin C X cgD cos D D Ycg sin D sin C x2C C C cos y2 Body C y sin D x2D 0 D D cos y2 0 The location of the joint relative to the c.g. is needed to define the parameters x2C C & y2 From the picture, Joint 2 x 41.3 mm x 41.3 C 2 y2C 0 © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 2nd Revolute Joint Module 3 – Constraint Equations Page 23 General Form of Constraint Equation X cgC cos C C Ycg sin C sin C x2C C C cos y2 X cgD cos D D Ycg sin D sin D x2D 0 D D cos y2 0 The location of the joint relative to the c.g. is needed to define the parameters x2D D y & 2 From the picture, y x Joint 2 x2D 43 43 mm y 0 D 2 © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 2nd Revolute Joint Module 3 – Constraint Equations Page 24 Using the geometry from the connecting rod and crank shaft, the revolute joint constraint equation becomes x 41 .3 x2D 43 y 0 y2D 0 C 2 C 2 C X cg cos C C Ycg sin C X cgD cos D D Ycg sin D © 2011 Autodesk sin C x2C C C cos y2 sin D x2D 0 D D cos y2 0 Joint 2 2nd Revolute Joint Constraint Equations X cgC 41.3 cos C X cgD 43 sin D 0 YcgC 41.3 sin C YcgD 43 cos D 0 Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation 3rd Revolute Joint Module 3 – Constraint Equations Page 25 General Form of Constraint Equation X cgD cos D D Ycg sin D X cgE cos E E Ycg sin E sin D x2D D D cos y2 sin E x2E 0 E E cos y2 0 The c.g.’s of both the crank and crank shaft lie at the origin of the global coordinate system. Therefore, the body fixed coordinates of the joint relative to the c.g. are zero. © 2011 Autodesk Joint 3 3rd Revolute Joint Constraint Equations Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. X cgD X cgE 0 D E Ycg Ycg 0 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Summary of Revolute Joint Equations Module 3 – Constraint Equations Page 26 Body C Body B Body C 2nd Revolute Joint Body D Joint 2 Joint 1 C X cgB 28cos B X cg 102.6 sin C 0 C X cg 41.3 cos C X cgD 43sin D 0 YcgB 28sin B YcgC 102.6 cos C 0 YcgC 41.3 sin C YcgD 43cos D 0 Joint 3 Body D © 2011 Autodesk Body E X cgD X cgE 0 D E Ycg Ycg 0 Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Module 3 – Constraint Equations Page 27 In the planar system the cylindrical joint between the cylinder liner and the piston acts like a prismatic joint. A prismatic joint allows two bodies to translate relative to each other along a common axis. The two bodies cannot rotate independent of each other. The equations for a planar prismatic joint are based on the geometry shown in the figure. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. yA Y Common Axis Body B Body A yA xA B xA A X Two bodies A & B that translate relative to one another along a common axis. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Constraint Equations Module 3 – Constraint Equations Page 28 The points P and Q in Body A lie on the common axis and are connected by the vector PQ. The points R and S in Body B lie on the common axis and are connected by the vector RS. The vector PR also lies on the common axis and connects the points P and R. The three vectors must be parallel. Alternatively, vectors PR and RS must be perpendicular to PQ . © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. yA Y Common Axis Body B R S Body A PQ yA Q xA B xA P A X Two bodies A & B that translate relative to one another along a common axis. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Constraint Equations Module 3 – Constraint Equations Page 29 The vector PQ with components written with respect to the body fixed coordinate system of Body A are A ˆ A ˆ PQ xPQ i y PQ j The components of the vector PQ with respect to the global coordinate system are A X PQ cos A A YPQ sin A © 2011 Autodesk A sin A xPQ A cos A y PQ Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. yA Y Body B R S Body A PQ yA Q xA B xA P A X Two bodies A & B that translate relative to one another along a common axis. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Constraint Equations Module 3 – Constraint Equations Page 30 The vector RS with components written with respect to the body fixed coordinate system of Body B are B ˆ B ˆ RS xRS i y RS j © 2011 Autodesk Y Body B R B sin xRS B B cos y RS S Body A PQ The components of the vector RS with respect to the global coordinate system are B X RS cos B B B Y sin RS yA yA Q xA B xA P A X B Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. Two bodies A & B that translate relative to one another along a common axis. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Constraint Equations Module 3 – Constraint Equations Page 31 The third vector is directed from point P to point R. Point P has the coordinates X X Y Y A P A P A CG A CG cos A sin A x y A p A p Y Body B R S Body A PQ Point R has the coordinates B cos B X RB X CG B B B YR YCG sin sin cos A A yA sin B xRB cos B y RB yA Q xA B xA P A The vector has components B cos B X PR X CG B B YPR YCG sin A X CG cos A A A YCG sin © 2011 Autodesk sin B xRB cos B y RB sin A xPA cos A y PA Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. X Two bodies A & B that translate relative to one another along a common axis. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Constraint Equations Module 3 – Constraint Equations Page 32 The vector perpendicular to PQ has components A A X PQ cos A A YPQ sin A sin A 0 1 xPQ y A A 1 0 cos PQ yA Y R X PR 0 Y PR X A PQ PR X PQ X A X PQ 0 Y © 2011 Autodesk A PQ B RS B RS S Body A PQ The dot product of two vectors that are perpendicular to each other is zero. A PQ PR X PQ Body B yA Q xA B xA P A X First Constraint Eq. Second Constraint Eq. Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. Two bodies A & B that translate relative to one another along a common axis. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Constraint Equations Module 3 – Constraint Equations Page 33 Substituting the vector components from the previous slides into the first constraint equation yields A PQ PR X PQ 0 1 cos 1 0 A sin T x A PQ y A PQ A A T sin cos A X A PQ B X CG cos B B YCG sin B X PR 0 YPR A cos A sin B xRB X CG B B A cos y R YCG sin A sin A xPA 0 A A cos y P Substituting the vector components from the previous slides into the second constraint equation yields A PQ PR X PQ 0 1 cos A 1 0 A sin T x © 2011 Autodesk A PQ y A PQ X A PQ sin A cos A T B X RS B 0 YRS cos B sin B B sin B xRS 0 B B cos y RS Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Summary of Prismatic Constraint Equations Module 3 – Constraint Equations Page 34 The two constraint equations for a planar prismatic joint are 1st Constraint Equation 0 1 cos A 1 0 A sin T x A PQ y A PQ sin A cos A T B B X CG cos B B Y sin CG A cos A sin B xRB X CG B B A cos yR YCG sin A sin A xPA 0 A A cos yP 2nd Constraint Equation 0 1 cos A 1 0 A sin T x A PQ y A PQ sin A cos A T cos B sin B B sin B xRS 0 B B cos y RS The vector components at the beginning and end of each equation are based on the body fixed coordinate systems and are constant. The only variables are the generalized coordinates of Body A and B. These equations are easily evaluated in a computer program. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Module 3 – Constraint Equations Page 35 The prismatic joint formed by the cylinder liner and the piston lies along the global Xaxis. Point P is chosen to lie at the c.g. of the cylinder liner. Point Q is chosen to lie 1 mm to the right on the x-axis. Point R is chosen to lie at the c.g. of the piston. Point S is chosen to lie 1 mm to the right on the x-axis. © 2011 Autodesk y y x x P Q Vector components of PQ S Vector components of RS A xPQ 1 B xRS 1 A y PQ 0 Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. R Point Coordinates B y RS 0 B xPA 0 xR 0 B y PA 0 y R 0 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Prismatic Joint Module 3 – Constraint Equations Page 36 Substitution of the vector components and point coordinates into the two prismatic joint equations yields 1st Constraint Equation 0 1 cos A 1 0 A 1 0 sin T sin A cos A T B X CG cos B B YCG sin B A cos A sin B 0 X CG B A cos 0 YCG sin A sin A 0 0 A cos 0 which reduces to 0 1 cos A 1 0 A 1 0 sin T sin A cos A T B A X CG X CG B A 0 YCG YCG 2nd Constraint Equation 0 1 cos 1 0 A 1 0 sin T © 2011 Autodesk A A T sin cos A cos B sin B Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. sin B 1 0 B cos 0 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Motion Constraint Module 3 – Constraint Equations Page 37 One motion constraint is required to make the mechanism stable. The rotation of the crankshaft (Body D) will be given an angular speed of 3,000 rpm. A 3,000 rpm engine speed is equal to 314 rad/sec. Although all fifteen generalized coordinates are a function of time, this is the only constraint equation that explicitly contains time as a variable. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. Motion Constraint D 314 t 0 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Summary of Constraint Equations Module 3 – Constraint Equations Page 38 There are five planar bodies each having three DOF giving a total of fifteen DOF. Fifteen unknowns requires fifteen equations. Revolute Joint 3 Revolute Joint 1 Ground Constraint 1 1) X 156.8 0 7) X 41.3 cos X 43 sin 0 11) X cgD X cgE 0 2)Y 0 8)Y 41.3 sin Y 43 cos 0 12)YcgD YcgE 0 A cg A cg C cg C C cg C D cg D cg D D 3) cgA 0 Revolute Joint 2 Ground Constraint 2 Motion Constraint 4) X cgE 0 9) X cgB 28 cos B X cgC 102.6 sin C 0 5)YcgE 0 10)YcgB 28 sin B YcgC 102.6 cos C 0 6) cgE 0 Prismatic Joint 0 1 cos A 13) 1 0 A 1 0 sin T 0 1 cos A 14) 1 0 A 1 0 sin T © 2011 Autodesk 15) D 314 t 0 B A X CG sin X CG 0 A B A cos YCG YCG A T sin cos B cos A sin B A T Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. sin B 1 0 B cos 0 www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Summary of Constraint Equations Module 3 – Constraint Equations Page 39 © 2011 Autodesk Only one of the constraint equations is time dependent (Motion Constraint). Most of the constraint equations are non-linear. All of the constraints are algebraic equations and none are differential equations. Geometric quantities (dimensions and distances) contained in the constraint equations can be found from information in a 3D CAD model. Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community Section 4 – Dynamic Simulation Module Summary Module 3 – Constraint Equations Page 40 The constraint equations for ground, revolute, and prismatic joints have been developed for a planar mechanism. The constraint equation for a rotational motion constraint has been developed for a planar mechanism. These equations were used to determine the fifteen equations necessary for a piston-crank assembly taken from a Boxer engine model. In some cases the constraint equations are very simple and in other cases they are complex. Only the motion constraint is an explicit function of time. All of the constraint equations are algebraic. These equations will be applied in the next module: Module 4. © 2011 Autodesk Freely licensed for use by educational institutions. Reuse and changes require a note indicating that content has been modified from the original, and must attribute source content to Autodesk. www.autodesk.com/edcommunity Education Community