Or Specially Orthotropic Lamina

advertisement

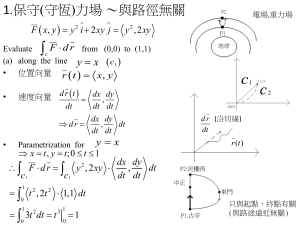

Micromechanics Macromechanics Fibers Lamina Laminate Structure Matrix Macromechanics Study of stress-strain behavior of composites using effective properties of an equivalent homogeneous material. Only the globally averaged stresses and strains are considered, not the local fiber and matrix values. Stress-Strain Relationships for Anisotropic Materials First, we discuss the form of the stress-strain relationships at a point within the material, then discuss the concept of effective moduli for heterogeneous materials where properties may vary from point-to-point. General Form of Elastic - Relationships for Constant Environmental Conditions ij Fij (11 , 12 , 13 ,...), i, j 1, 2,3... (2.1) Each component of stress, ij, is related to each of nine strain components, ij (Note: These relationships may be nonlinear) Expanding Fij in a Taylor’s series and Retaining only the first order terms, ij Cijkl kl , i, j, k , l 1,2,3 for a linear elastic material ij 9 com ponents kl 9 com ponents Cijkl 81 com ponents 3D state of stress Generalized Hooke’s Law for Anisotropic Material 11 22 C1111 33 C 2211 C 3311 23 C 2311 31 = C 3111 C1211 12 ... C 3211 32 C 13 1311 C 2111 21 C C C C C C 1122 2222 3322 2322 3122 1222 ... C C C 3222 1322 2122 C C C C C C 1133 2233 3333 2333 3133 1233 ... C C C 3233 1333 2133 C C C C C C 1123 2223 3323 2323 3123 1223 ... C C C 3223 1323 2123 C C C C C C 1131 2231 3331 2331 3131 1231 ... C C C 3231 1331 2131 C C C C C C 1112 2212 3312 2312 3112 1212 ... C C C 3212 1312 2112 .. C C C C C C 1132 2232 3332 2332 3132 1232 ... C C C 3232 1332 2132 C C C C C C 1113 2213 3313 2313 3113 1213 ... C C C 3213 1313 2113 2221 3321 2321 3121 1221 ... C 3221 C1321 C 2121 C C C C C C 1121 11 22 33 23 31 12 32 13 21 (2.2) Symmetry Simplifies the Generalized Hooke’s Law 1. Symmetry of shear stresses and strains: 21 2 1 O 12 Static Equlibrium M 0 im plies 12 21 or in general, 0 ij ji or ij ji Same condition for shear strains, ij ji 2. Material property symmetry – several types will be discussed. Symmetry of shear stresses and shear strains: ij ji and ij ji Thus, only 6 components of ij are independent, and likewise for ij. This leads to a contracted notation. Stresses Tensor Notation Contracted Notation 11 1 22 2 33 3 23= 32 4 13= 31 5 12= 21 6 Strains Tensor Notation Contracted Notation 11 1 22 2 33 3 2 23= 2 32= 23= 32 4 2 13= 2 31= 13= 31 5 2 12= 2 21= 12= 21 6 Geometry of Shear Strain xy xy 2 xy = Engineering Strain xy = Tensor Strain xy xy 2 Total change in original angle = xy Amount each edge rotates = xy/2 = xy Using contracted notation i Cij j i, j 1,2,...,6 or in matrix form C (2.3) (2.4) where and are column vectors and [C] is a 6x6 matrix (the stiffness matrix) Alternatively, i Sij j i, j 1,2,...,6 or S (2.5) (2.6) where [S] = compliance matrix and S C 1 Expanding: 1 S11 S 2 21 3 S31 4 S 41 5 S51 6 S 61 S12 S13 S14 S15 S 22 S 23 S 24 S 25 S32 S 42 S33 S 43 S34 S 44 S35 S 45 S52 S53 S54 S55 S 62 S 63 S 64 S 65 S16 1 S 26 2 S36 3 S 46 4 S56 5 S 66 6 • Up to now, we only considered the stresses and strains at a point within the material, and the corresponding elastic constants at a point. • What do we do in the case of a composite material, where the properties may vary from point to point? • Use the concept of effective moduli of an equivalent homogeneous material. Concept of an Effective Modulus of an Equivalent Homogeneous Material Heterogeneous composite under varying stresses and strains x3 d 2 L x3 2 2 Stress, 2 Equivalent homogeneous x 3 material under average stresses and strains 2 2 Strain, 2 x3 2 2 Stress Strain 2 Effective moduli, Cij i Cij j where, i average stress (2.9) i dv v (2.7) dv v i average strain i dv v (2.8) v dv 3-D Case General Anisotropic Material • [C] and [S] each have 36 coefficients, but only 21 are independent due to symmetry. • Symmetry shown by consideration of strain energy. • Proof of symmetry: Define strain energy density 1 W i i i 1,2,...,6 2 1 1 1 W 11 11 ... 6 6 2 2 2 but i Cij j 1 W Cij i j 2 (2.12) Now, differentiate: but j j W 1 1 Cij j Cij i i 2 2 i ij Kronecker delta 1 if i=j i 0 if ij ij i j (show) W Cij j i 2W Cij i j (2.11) (2.13) But if the order of differentiation is reversed, W C ji j i 2 (2.14) Since order of differentiation is immaterial, Cij C ji (Symmetry) Similarly, 1 W S ij i j 2 and Sij S ji Only 21 of 36 coefficients are independent for anisotropic material. Stiffness matrix for linear elastic anisotropic material with no material property symmetry (2.15) 3-D Case, Specially Orthotropic 3 2 1 1, 2 , 3 principal material coordinates 1 12 2 2 1 (a) 12 (b) (c) Simple states of stress used to define lamina engineering constants for specially orthotropic lamina. Consider normal stress 1 alone: 3 1 1 1 2 Resulting strains, 1 1 E1 ; 2 121 12 1 E1 (2.19) Typical stress-strain curves from ASTM D3039 tensile tests Stress-strain data from longitudinal tensile test of carbon/epoxy composite. Reprinted from ref. [8] with permission from CRC Press. Similarly, 3 131 13 1 E1 where E1 = longitudinal modulus ij = Poisson’s ratio for strain along j direction due to loading along i direction Now consider normal stress 2 alone: Strains: 2 2 E2 2 3 ; 2 1 21 2 21 E2 2 3 23 2 23 E2 Where E2 = transverse modulus Similar result for 3 alone 1 2 2 (2.20) • Observation: All shear strains are zero under pure normal stress (no shear coupling). 12 13 23 0 For 1, 2 , 3 alone Now, consider shear stress 12 alone, 3 1 Strain 12 12 2 12 12 G12 Where G12 = Shear modulus in 1-2 plane 1 2 3 13 23 0 (No shear coupling) (2.21) Similarly, for 13 alone 13 13 G13 ; 1 2 3 12 23 0 and for 23 alone 23 23 G23 ; 1 2 3 13 12 0 Now add strains due to all stresses using superposition Specially Orthotropic 3D Case 1 E 1 12 1 E1 2 13 3 E1 23 0 31 12 0 0 21 E2 31 E3 0 0 1 E2 32 E3 0 0 23 E2 1 E3 0 0 0 0 1 G23 0 0 0 0 1 G31 0 0 0 0 0 0 1 2 0 3 0 23 31 0 12 1 G12 12 coefficients, but only are 9 independent (2.22) Symmetry: Sij S ji ij Ei ji Ej Only 9 independent coefficients. Generally orthotropic 3-D case – similar to anisotropic with 36 nonzero coefficients, but 9 are independent as with specially orthotropic case Specially Orthotropic – Transversely Isotropic 3 2 1 Fibers randomly packed in 2-3 plane, so properties are invariant to rotation about 1-axis (2 same as 3) Specially orthotropic, transversely isotropic (2 and 3 interchangeable) G13 G12 , E2 E3 , 21 31 E2 G23 2(1 32 ) (2.23) Now, only 5 coefficients are independent. Isotropic G13 G23 G12 G E1 E2 E3 E 12 23 13 E G 2(1 ) 2 independent coefficients Usually measure E, υ – calculate G Isotropic – 3D case 1 E 1 E 2 3 E 4 0 5 6 0 0 E 1 E E E E 1 E 0 0 0 0 0 0 0 0 1 G 0 0 0 0 1 G 0 0 0 0 0 0 1 2 0 3 0 4 5 0 6 1 G Same form for any set of coordinate axes 3-D Isotropic – stresses in terms of strains E (1 ) x ( y z ) x (1 )(1 2) E (1 ) y ( x z ) y (1 )(1 2) E (1 ) z ( x y ) z (1 )(1 2) xy G xy E xy 2(1 ) xy G xy E xy 2(1 ) xy G xy E xy 2(1 ) 3-D Case, Generally Orthotropic z y x Material is still orthotropic, but stress-strain relations are expressed in terms of non-principal xyz axes Generally Orthotropic x S 11 y S 21 z S 31 yz S 41 zx S 51 xy S 61 S 12 S 22 S 32 S 42 S 52 S 62 S 13 S 23 S 33 S 43 S 53 S 63 S 14 S 24 S 34 S 44 S 54 S 64 S 15 S 25 S 35 S 45 S 55 S 65 S 16 x S 26 y S 36 z S 46 yz S 56 zx S 66 xy Same form as anisotropic, with 36 coefficients, but 9 are independent as with specially orthotropic case Elastic coefficients in the stress-strain relationship for different materials and coordinate systems Material and coordinate system Number of nonzero coefficients Number of independent coefficients Anisotropic 36 21 Generally Orthotropic (nonprincipal coordinates) 36 9 Specially Orthotropic (Principal coordinates) 12 9 Specially Orthotropic, transversely isotropic 12 5 Isotropic 12 2 Anisotropic 9 6 Generally Orthotropic (nonprincipal coordinates) 9 4 Specially Orthotropic (Principal coordinates) 5 4 Balanced orthotropic, or square symmetric (principal coordinates) 5 3 Isotropic 5 2 Three – dimensional case Two – dimensional case (lamina) 2-D Cases Use 3-D equations with, 3 13 23 0 Plane stress, 1 , 2 , 12 , 0 Or x , y , xy , 0 Specially Orthotropic Lamina 1 S11 2 S 21 0 12 S12 S 22 0 0 1 0 2 (2.24) S 66 12 Or 2 1 1 Q11 Q12 2 Q21 Q22 0 0 12 0 1 (2.26) 0 2 Q66 12 5 Coefficients - 4 independent Specially Orthotropic Lamina in Plane Stress 1 S11 2 S 21 0 12 S12 S 22 0 0 1 0 2 S 66 12 5 nonzero coefficients 4 independent coefficients (2.24) Or in terms of ‘engineering constants’ 1 S11 E1 1 S 22 E2 21 12 S12 S 21 E2 E1 1 S66 G12 (2.25) Experimental Characterization of Orthotropic Lamina • Need to measure 4 independent elastic constants • Usually measure E1, E2, υ12, G12 (see ASTM test standards later in Chap. 10) Stresses in terms of tensor strains, 1 Q11 Q12 2 Q21 Q22 0 0 12 0 1 0 2 (2.26) 2Q66 12 / 2 where Q S 1 Inverting [S]: S 22 E1 Q11 2 1 12 21 S11 S 22 S12 S12 12 E2 Q12 2 1 12 21 S11 S 22 S12 S11 E2 Q22 2 1 12 21 S11 S 22 S12 1 Q66 G12 S66 Off – Axis Compliances: S ij f ij all Sij and angle Off – Axis Stiffnesses: Q ij f ij ' all Qij and angle Where fij and fij’ are found from transformations of stress and strain components from 1,2 axes to x, y axes Sign convention for lamina orientation y y 1 2 2 x x Positive Negative 1 Stress Transformation: 2 dAsin Y 2 1 12 dAsin X 12dAcos 1dAcos F x xydA 0 and Fy 0 x dA dA F x x dA 1dAcos 2 dAsin 2 2 2 12 dAsin cos 0 x 1 cos 2 sin 212 sin cos 2 F y 2 0 xy 1 cos sin 2 cos sin 12 (cos sin ) 2 2 Equations used to generate Mohr’s circle. (2.29) Resulting stress Transformation: 2 2 c s 2cs 1 X 1 2 1 2 c 2cs 2 T 2 Y s cs cs c 2 s 2 XY 12 12 Where c cos , s sin or 1 X 2 T Y 12 XY (2.31) (2.30) Where c2 s2 2cs 2 2 [T ] s c 2cs cs cs c 2 s 2 (2.32) Strain Transformation: x 1 2 T y / 2 / 2 12 xy (2.33) Recall: Tensor shear strain xy 1 xy 2 Where xy = engineering shear strain or x 1 1 y T 2 / 2 / 2 12 xy Substituting (2.33) into (2.26), then substituting the resulting equations into (2.30) x x (2.34) 1 y [T ] [Q][T ] y / 2 xy xy Carrying out matrix multiplications and converting back to engineering strains, x Q11 Q12 Q16 x y Q12 Q 22 Q 26 y Q Q Q 26 66 xy xy 16 (2.35) Where Q11 Q11c Q22 s 2(Q12 2Q66 )s c 4 4 2 2 Q11 (2.36) Q 66 Alternatively x S 11 y S 12 S 16 xy Where S 1 S 12 S 22 S 26 [Q] S 16 x S 26 y S 66 xy (2.37) Generally Orthotropic Lamina (Off Axis) x S 11 y S 12 S 16 xy S 12 S 22 S 26 S 16 x S 26 y S 66 xy (2.37) Or x 2 1 y x Q11 Q12 y Q12 Q 22 Q xy 16 Q 26 Q16 x Q 26 y Q 66 xy 9 Coefficients - 6 independent In expanded form: S11 S11c 4 2S12 S66 s 2c 2 S 22 s 4 S12 S12 s 4 c 4 S11 S 22 S66 s 2c 2 S22 S11s 4 2S12 S66 s 2c 2 S 22c 4 (2.38) S16 2S11 2S12 S66 sc3 2S 22 2S12 S66 s 3c S26 2S11 2S12 S66 s 3c 2S 22 2S12 S66 sc 3 S66 2 2S11 2S22 4S12 S66 s 2c 2 S66 s 4 c 4 Off-axis lamina engineering constants Young’s modulus, Ex 2 y x x 1 or Ex x Ex x When x 0, y xy 0 x 1 Ex (2.39) S 11 x S 11 1 1 4 212 1 2 2 1 4 c s c s E1 G12 E2 E1 (2.40) Complete set of transformation equations for lamina engineering constants 1 1 2 1 4 Ex c 4 12 s 2 c 2 s E1 E2 G12 E1 1 1 4 1 212 2 2 1 4 Ey s c s c E G E E 1 1 2 12 1 1 1 1 212 1 Gxy s4 c4 4 E1 2G12 G12 E1 E2 12 4 1 1 1 2 2 4 xy Ex s c s c E E E G 1 2 12 1 (2.40) 2 2 s c 1 Variations of off-axis engineering constants with lamina orientation for unidirectional carbon/epoxy, boron/aluminum and glass/epoxy composites. (From Sun, C.T. 1998. Mechanics of Aircraft Structures. John Wiley & Sons, New York. With permission.) Shear Coupling Ratios, or Mutual Influence Coefficients • Quantitative measures of interaction between normal and shear response. • Example: when x 0, y xy 0, Shear Coupling Ratio xy S 16 x S 16 x, xy x S 11 x S 11 Analogous to Poisson’s Ratio (2.41) Example of off-axis strain in terms of off-axis engineering constants yx xy , x 1 x x y xy Ex Ey Gxy (2.43) Compliance matrix is still symmetric for off-axis case, so that, for example S12 S21 and yx Ey xy Ex Balanced Orthotropic Lamina (Ex: Woven cloth, cross-ply) E1 E2 2 Q11 Q22 S11 S22 1 Only 3 independent coefficients Lamina Stiffness Transformations Q11 c 4 4 Q 22 s Q c 2 s 2 12 2 2 Q 66 c s Q c 3 s 16 3 Q 26 cs s4 2c 2 s 2 4c 2 s 2 4 2 2 2 2 Q c 2c s 4c s 11 Q 2 2 4 4 2 2 c s c s 4c s 22 2 2 2 2 2 2 2 c s 2c s (c s ) Q12 3 3 3 3 3 cs cs c s 2(cs c s ) Q66 3 3 3 3 3 c s c s cs 2(c s cs ) Use of Invariants The lamina stiffness transformations can be written as: Q11 U1 U 2 cos 2 U 3 cos 4 Q12 U 4 U 3 cos 4 Q 22 U1 U 2 cos 2 U 3 cos 4 U2 sin 2 U 3 sin 4 Q16 2 U2 sin 2 U 3 sin 4 Q 26 2 (2.44) Where the invariants are 1 U1 (3Q11 3Q22 2Q12 4Q66 ) 8 1 U 2 (Q11 Q22 ) 8 1 U 3 (Q11 Q22 2Q12 4Q66 ) 8 1 U 4 (Q11 Q22 6Q12 4Q66 ) 8 1 U 5 (Q11 Q22 4Q66 2Q12 ) 8 (2.45) Alternatively, the off-axis compliances can be expressed as S11 V1 V 2 cos 2 V 3 cos 4 S12 V 4 V 3 cos 4 S 22 V1 V 2 cos 2 V 3 cos 4 S16 V 2 sin 2 2V 3 sin 4 S 26 V 2 sin 2 2V 3 sin 4 S 66 2(V1 V 4 ) 4V 3 cos 4 (2.46) where the invariants are 1 V1 (3S11 3S 22 2S12 S 66 ) 8 1 V 2 (S11 S 22 ) 2 1 V 3 (S11 S 22 2S12 S 66 ) 8 1 V 4 (S11 S 22 6S12 S 66 ) 8 (2.47) Example: decomposition of Q11 using invariants Q11 U Q11 0 2 1 0 U3 cos4 U 2 cos2 U1 U2 0 2 U3 0 2 2 References: Mechanics of Composite Materials, Jones Introduction to Composite Materials, Tsai & Hahn Invariants in transformation of stresses: Mohr’s circle Ex : x I R cos2 R x 2 p Where I I x y 2 p (2.48) Invariant x y 2 xy Invariant R 2 2 Similar graphical interpretation of stiffness transformations Ex: Q11 U1 U2 cos2 U3 cos4 Isotropic Part Orthotropic Part (2.49) U1 and U4: First order invariants U2 and U3: Second order invariants Radii of circles indicates degree of orthotropy. (i.e., if U2=U3=0, we have isotropic material)