UNIT 11: MEATS

Chapters 3, 7-9

Objectives

Understanding of where meats come from

Knowledge of Grading meats

Appreciation for live animal meat evaluation

Knowledge of various cuts of meats

Understanding of animal by-products and their

places in the industry

Sources of Red Meats

Beef-from cattle > 1 yr. of age

Veal-calves from 3 mos. or younger

Pork-swine

Mutton-mature sheep

Lamb-young sheep

Chevon-goats (goat meat)

Figure 9.4

Location of the wholesale cuts on the live steer, pig, and lamb. Source: Colorado State University.

World Supply

~3.5b lbs.

Red meats accounts for over 85% of all production

U.S., China, Russia main suppliers

U.S. production of beef & pork >50b lbs.

Products

Use CO2 or stunning to render animal unconscious,

cut jugular before removing hide/scales

Drop separated from carcass

Head

Hide

Hair

Shanks

Organs

Products

Dressing percentage

Carcass

wt divided by live wt * 100

Average dressing percentages

Hogs

– 72%

Cattle – 60%

Sheep – 50%

Factors

affecting dressing %

Fill

Fatness

Muscling

Wt

of hide

Wt of wool

Products

Beef/Pork carcasses are split down the backbone

into halves

Can

be stored in a cooler 28-32F

Can be stored several weeks, most are only a day or

two

Larger

companies move meat faster

Small packers may allow meat to age and tenderize

Products

Shipping meats

Used

to ship in carcass form

Today, most packers process into wholesale/primal cuts

or even to retail cuts (boxed meats)

Figure 3.1

Annual commercial red meat production by type of meat. Source: Livestock Marketing Information Center.

Figure 3.2

Center.

Commercial cattle harvest in the United States, 2005 (1,000 head). The top 10 states are circled. Source: Livestock Marketing Information

Figure 3.3

Commercial hog slaughter 2005 (1,000 head). Source: Livestock Marketing Information Center.

Kosher & Muslim Meats

Specific rules for the slaughter of religiously

acceptable animals

Kosher meats

Comes

from animals w/ split hooves, chew cud,

slaughtered according to Jewish Law

Also prohibitions against mixing meat/milk

Can only be slaughtered by specifically trained persons

Must not eat blood, or parts containing blood…specific

arteries & veins must be removed

$100 m in sales each yr in U.S.

Kosher & Muslim Meats

Any Muslim may slaughter an animal

Can

also be slaughtered by others while approved

people present

Composition

Physical

Lean,

fat, bone, connective tissue

Proportions change over time

Chemical

65-75%

water

15-20% protein

2-12% fat

1% minerals

What happens to these ratios as the animal gets older?

Figure 3.8

The fundamental structure of meat and muscle in the beef carcass.

Nutritional Considerations

Nutritive Value

High

nutrient density foods

High in vits, mins, iron, protein, essential amino acids

Research focused on development of more, new cuts of

meat to increase consumption, health benefits, etc.

Consumption

Consumed for both satisfaction & nutritional content

Actual consumption data difficult to collect due to

variation in cuts, waste amounts, etc.

Changes in prices of meat products results in shifts in

demands back and forth from poultry and red

meats

Figure 3.10

Annual U.S. red meat and poultry consumption (boneless weight). Source: Livestock Marketing Information Center.

Figure 3.11 Daily per-capita meat consumption as part of meat, poultry, fish, dry beans, eggs, and nuts group (Food Guide Pyramid). Source:

National Live Stock and Meat Board.

Demand

Seems to be better barometer than per-capita

consumption

Price at which consumer will buy a specific

quantity…all other factors being equal

Drives not only meat purchases…but the livestock

population numbers on the farm

Figure 3.12

Annual retail meat and poultry prices (Nominal basis). Source: Livestock Marketing Information Center.

Figure 3.15

Annual per-capita U.S. expenditures for meat and poultry. Source: Livestock Marketing Information Center.

Marketing

Terminal markets

Large,

livestock collection centers

Sale Barns

Located

all across the U.S.

Purchased on live weight basis, buyer estimates value

of the carcass

Grade and Yield

Some

animals purchased on carcass merit basis

Cuts out the middle man to some extent, but also lower

the live weight market price

Marketing

Interesting facts:

½

of all food taken home to be prepared

½ of white collar workers eat 1 meal/d at their desk

¼ of calories consumed in form of snack foods

10% of all food consumed in a vehicle

Consumer confusion regarding what meat to purchase

and how to prepare it

¾ of consumers have no evening meal plan at end of

the day

Marketing

Shifts

Mid

in consumer preference changes producer goals

80’s demand for leaner meats

Producers changed genetics, feeding, etc.

Resulted in loss in sales due to loss of taste

Only when producers matched leanness and marbling did

consumption begin to rise

Market Classes & Grades of Livestock

99$b of meat products are marketed annually

Market Classes and Grades

Segregates

animals, carcasses, and products into

uniform groups based on buyer and seller preferences

Established by USDA, but not mandatory

Most

comply

Meat inspection is mandatory

Market Classes and Grades

Slaughter Cattle

Veal

1-3 mos. <150 lbs.

Calf 3-10 mos. 150-300 lbs.

Beef >12 mos. Carcass wt. >300 lbs.

Also separated by sex classes

Heifer,

cow, steer, bull, bullock, stag

Separates carcasses into more uniform wts.

Market Classes and Grades

Quality

Grades

Measures

consumer palatability characteristics.

Maturity

Observed by bone/cartilage structures

Marbling

Intramuscular fat, or flecks of fat within the lean

Evaluated at the exposed rib-eye muscle between 12th and 13th

ribs

10 degrees are established from abundant to devoid

Figure 8.1

USDA quality grades (Commercial, Cutter, and canner omitted). Courtesy of USDA.

Figure 8.3

Relationship between marbling, maturity, and carcass quality grade. Source: USDA.

Figure 8.4 Exposed ribeye muscles (between the 12th and 13th ribs) showing various degrees of marbling associated with several beef carcass

quality grades. Courtesy of the American Meat Science Association copyrighted 1997.

Figure 8.5

Location of the fat measurement over the ribeye (longissimus dorsi) muscle. Source: Colorado State University.

Market Classes and Grades

Yield

Grades (aka cutability grades)

Measures

quality of boneless, closely trimmed retail cuts

from major wholesale cuts of beef (round, loin, rib, chuck)

Yield Grade

% BCTRC

1

> 52.3

2

52.3 - 50.0

3

50.0 - 47.7

4

47.7 - 45.4

5

< 45.4

Figure 8.2

USDA yield grades for market cattle. Courtesy of USDA.

Figure 8.7

The five yield grades of beef shown at the 12th and 13th ribs. Courtesy of American Meat Science Association copyrighted 1997.

Figure 8.8 Quality grades and yield grades of beef, 2004. Note: Approximately 10% of total carcasses are not quality or yield graded,

respectively. Quality and yield grade percentages do not equal 100% due to rounding error. Source: USDA.

Market Classes and Grades

Feeder Cattle

Feeder

grades used to predict wt gain & slaughter wt

end point of cattle fed to a desirable fat-to-lean

composition

Two criteria

Frame

size

Thickness

Figure 8.9

The three frame sizes of the USDA feeder cattle grade system. Source: USDA.

Figure 8.10

The four thickness standards of the USDA feeder cattle grade system. Source: USDA.

Carcass Composition Display

Preferred proportion of fat:lean has changed over

the years

How/Why?

Yield Grades determined from 4 carcass

characteristics:

Amount

of fat in .1” over the rib-eye muscle

Kidney, pelvic, heart fat

Area of the rib-eye muscle in sq. in.

Hot carcass wt.

Carcass Composition Display

Quality and Yield grading is voluntary, however,

about 90% is quality graded, and 84% is yield

graded

Carcass Composition Display

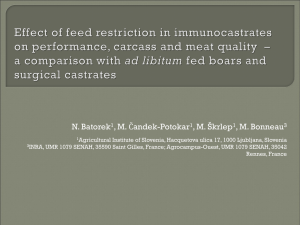

Slaughter Swine

Sex

Classes

Barrow,

gilt, sow, boar, stag

What is the difference?

Traditional

grades for Barrow/Gilt carcasses based on

two characteristics

Quality

of the lean

Expected combined yields of for lean cuts:

Ham

Loin

Blade Shoulder

Picnic Shoulder

Carcass Composition Display

Two

quality grades for lean in pork carcasses:

at the exposed surface of a cut muscle at the 10th

and 11th ribs

Acceptable

Observed

Gray/pink in color

Fine muscle fibers

Fine marbling

Graded 1-4 depending on the amount of lean

Unacceptable

Too dark/pale

Soft

Watery

Bellies are too thin for bacon

Visual Perspective of Carcass

Composition of the Live Animal

Goal: large amounts of highly palatable lean w/

minimal amounts of fat & bone

Sizes and shapes of cattle, swine, sheep are

different, but muscle structure and fat deposition

areas are almost identical

Ex.

Animal w/ square appearance over top of back,

block and deep from the side has a large accumulation

of fat

Visual Perspective of Carcass

Composition of the Live Animal

Fat accumulation

Brisket

Dewlap

Jowl

Between

hind legs

Edge of loin

Behind the shoulders

Shoulder blade movement can be seen when lean

cattle/swine walk

Visual Perspective of Carcass

Composition of the Live Animal

Animals w/ oval shape to its back and thickness

through the center of hind legs have high proportion

of lean:fat

Fat on retail cuts has been reduced over the last 20

years

1/4

to 1/8 in, or none on many cuts

Reduction taken primarily by packer

Some breeding and feeding practices altered

This

is not highly encouraged

Why?

By-Products of Meat Animals

Can account for as much as 8-10% of the total

value of a fed steer

What are the by-products?

Two categories based on human consumption

Edible

& Inedible

Edible By-Products

Also called variety meats

Organs and body parts other than the carcass

What are some examples?

Liver, heart, tongue, tripe, sweetbread

Tripe-lining of the stomach

Sweetbread-thymus gland

Avg. 1100# steer produces ~36# of variety meats

Per capita consumption of variety meats is only ~9#

Much is exported

Lard and Tallow

Shortenings, margarines, pastries, candies

Inedible tallow goes into soap, lubricants, feed, fatty acids

~45% of inedible tallow, and ~20% of edible tallow are

exported

Inedible By-Products

Tallow, hides, inedible organs

Some

skins are edible

Many pharmaceuticals originate from these byproducts

Cholesterol

Corticosteroids

Epinephrine

Heparin

Rennet

Cortisone

Inedible By-Products

Hides

Cattle & buffalo hides account for ~80% of hides in the

world

$1.3 b exported from U.S. each year

Some goat and sheep skins ~$33m/yr.

One cowhide-144 baseballs, 20 footballs, 18 volleyballs,

12 baseball gloves, 12 basketballs

Leather use in the U.S.-40% upholstery, 50% shoes, 10%

other

Hide weighs>30lbs., skins<30lbs.

Skins w/ wool left on called pelts

Inedible By-Products

Value of hides can be reduced, how?

Hides worth ~$1/lb.

Fed steers produce ~65-75lbs. Of hide

After hides are treated (“blue” stage) they lose about 15

lbs.

Preserves for shipping

Value is increased to $80-90

60lb. Hide produces ~40 sq. ft. of leather

Tanners add ~$500m annually to hides

Hides are the most valuable by-product

7m tons of by-product ($8b) used to make pet food

Ex.

Inedible By-Products

Pet food exports tripled since 1990

Dog food sales ~$9m, extra $1b spent in treats

Rendered fats and oils are also used in the

manufacture of biodiesel

Currently used in some public transportation

systems

Figure 7.1

Edible and inedible by-products from a 1,100-lb steer. Source: USDA.

Figure 7.2

In addition to the retail product of beef are numerous by-products. Adapted from Field (1996).

Figure 7.3 Rib brands are a primary cause of lost value in hides. While many states require branding as verification of ownership, branding on the

upper or lower hip is preferred to minimize hide damage.

The Rendering Industry

What are their sources for product?

70m lbs. of animal material daily

Rendering of Red Meat Animal By-Products

Animal

fat and animal protein are the major products

Most fats go into animal feeds

The Rendering Industry

Fatty

acids

Plastics

Cosmetics

Lubricants

Paints

Deodorants

Cleaners

Caulk

Ink

Etc.

The Rendering Industry

Proteins

Processed

into >50% protein sources

Meat and Bone meal

Blood meal

Disposing of Dead Livestock

Do

not enter the food chain

Must be careful to avoid cross contamination to humans

or other livestock

The Rendering Industry

Protocol for disposal of dead stock

Removal by licensed rendering company

2. Compost the carcass

3. Burn in an approved incinerator (licensed)

4. Bury >4’ deep

1.