Beef Production Week 3 Winter Feeding of Beef Cattle

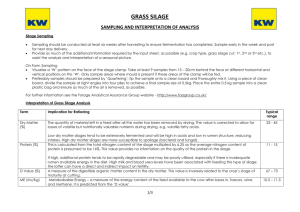

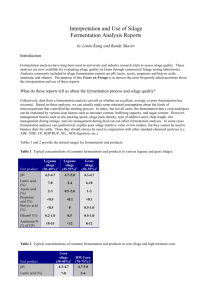

advertisement

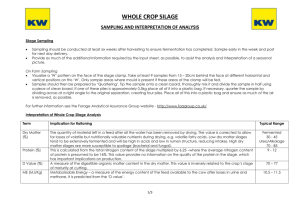

Level II Agricultural Business Operations • To gain an understanding of animal nutritional requirements •To asses the quality of silage •To assess the quantity of silage available for winter feeding •To gain understanding of the different types of concentrate feedstuffs available •To assess the quality of various feedstuffs Animals need a balanced diet containing the correct amounts of: Energy: for movement and growth Protein: for muscles, milk production, and embryo development Minerals: for bones and to maintain the animal’s system Water Food Fibre Carbohydrate Dry matter Protein Fats Mineral and vitamins All foods contain Water ---- the remaining part is called Dry Matter Cattle require energy for: Maintenance Production - Growth - Milk Energy (ME) is measured in megajoules (MJ) REQUIREMENT = MAINTENANCE + PRODUCTION Maintenance The amount of energy an animal needs for maintenance depends on their size A 400 kg store heifer requires 46MJ/day to maintain herself LWT 200 300 400 500 600 Maintenance Req. (MJ). 27 36 46 54 62 Liveweight Gain It takes 32MJ to produce 1kg of live-weight gain Milk Production It takes 5MJ to produce 1litre of milk A 400 kg store heifer growing at 0.5kg per day ◦ Maintenance requirement = 46MJ ◦ Growth: 32MJ per 1Kg x 0.5 = 16MJ _____ 62MJ Total Daily Requirement = All feed decisions revolve around meeting this target Silage forms the bulk of the livestock diet for six months of the year through the winter months. Silage is conserved grass that is made by farmers when the grass supply is plentiful. Silage is made by preserving the grass under naturally produced acidic conditions which effectively pickle the crop. Silage is quite moist and usually preferred by livestock to hay as it is more palatable and of higher food value. Target best silage to most productive stock – Finishing cattle Lactating cows Young growing cattle Dry cows To assess feed value, predicted animal performance and the need for supplementation. To identify early the stability of the silage and possible impacts on waste and animal health. • Wait until six weeks after harvest. •Take several cores across the clamp. • Squeeze air out before sealing tightly. • Send to lab early in the week. • Provide as much information as possible e.g. 1st or 2nd cut ME Value Indicates High quality silage Good quality silage Average quality silage Poor quality silage Metabolisable Measure of the energy energy (ME) content of the (MJ/kg DM) silage. >12 11.5-11.8 11.5 -10.5 <10.5 Crude protein (CP) (%) Measure of the silage crude protein content >13 11-13 10 – 11 <10 Dry matter (DM) (%) Measure of the quantity of material left after drying > 30 25 – 30 20 – 25 <20 Value Indicates High quality silage Good quality silage Average quali ty silage Poor quality silag e Metabolisable energy (ME) (MJ/kg DM) Measure of the energy content of the silage. >12 11.5-11.8 11.5 10.5 <10.5 Crude protein (CP) (%) Measure of the silage crude protein content >13 11-13 10 – 11 <10 Dry matter (DM) (%) Measure of the quantity of material left after drying > 30 25 – 30 20 – 25 <20 Value Metabolisable energy (ME) (MJ/kg DM) Indicates Measure of the energy content of the silage. High quality silage Good quality silage Average Poor quality quality silage sila ge >12 11.5-11.8 11.5 -10.5 <10.5 Crude protein (CP) (%) Measure of the silage crude protein content >13 11-13 10 – 11 <10 Dry matter (DM) (%) Measure of the quantity of material left after drying > 30 25 – 30 20 – 25 <20 pH is a measure of the acidity of the silage; it gives an indication of the fermentation quality and hence the ability of the silage to store. Ideally, silages will have a pH 3.8 – 4.2. Measuring Quantity Silo/Pit: Length (m) x Width (m) x Height (m) = Volume (m3) X Dry Matter Conversion factor = Tonnes of silage Example Calculation silage in pit 4? Width of pit = 10m Assume silage is 30% Dry matter 3m 30m 5m Section A: 30 x 3 x 10 = 900m3 Plus 10m wide 3m A B Section B: 5 x 3 x 10 = 150m3 X 0.5 = 75 m3 30m Total = 900 + 75 = 975m3 5m Conversion Factors Silage Dry Matter Conversion factor Tonnes of Silage = Silage Pit Volume x Dry Matter Conversion Factor 975 x 0.6 = 585 Tonnes of Silage Fodder Balance Worksheet Total Farm Example: Silage Stocks Silage stocks (t) Pit 1 475 Pit 2 460 Pit 3 430 Pit 4 535 Round bales 13 Total 1913 Silage Requirement Requirements Months Silage requirement 1.2 6.5 78 70 1.0 6.5 455 350+ kg 65 1.0 6.5 423 250 – 350 kg 70 0.8 6.5 364 200 – 250 kg 30 0.7 6 126 calves 25 0.3 6 45 Type of stock No Autumn calver 10 Spring calver per month (t) Total silage required 1491tonne • • • Ration ingredients Relative Feed Value Understanding feed labels Meal 14 % Moisture (Water) 86 % Dry Matter – minimum ME 12.5 MJ/kgDM Silage 75 % Moisture (Water) 25 % Dry Matter Meal is up to 4 x more concentrated energy than silage Straights Blends Pellets Coarse Feeds Blends, Pellets and Coarse feeds are a combination of straights, designed for a specific feed task Straights are individual feed ingredients. Can be classified as either: ◦ Energy sources ◦ Protein Sources ◦ Fibre Sources The combination of straights fed depends on: - Target animal performance - Cost (Relative Feed Value) - The quality of forage material available Protein Soya bean meal Rapeseed meal Peas & Beans Linseed Maize distillers Energy Barley Wheat Maize gluten Maize (yellow meal) Vegetable/fish oil Fibre Oats Beet pulp Citrus pulp Soya hulls Straw Feed Dried barley Wheat Maize Soya hulls Citrus pulp Sugar beet pulp Soyabean meal Rapeseed meal Maize distillers Maize gluten Protein% 9.5 11 8 10 6 9 46 36 26 18 ME 13.2 13.8 14.7 11.6 12.6 12.5 13.8 12.5 14.0 12.9 Relative value (£) 140 148 159 131 118 133 330 272 227 180 http://eservices.ruralni.gov.uk/onlineservices/Tools/Beef/relativeprog.asp Blends A mix of different straights blended together at the feed mill Cheapest form of buying meal apart from buying in the straights and mixing yourself Possible to buy a specified ration Potential to be dusty with poorer palatability Extra cost for pelleting Reduces dust significantly Prevents cattle picking out individual ingredients. Flows well in hoppers and meal bins. Most expensive way to make up a ration Used as away to improve intakes. Most coarse feeds are based on around 20-30% flaked maize- can separate out in creep feeders Often contains ingredients that are cooked or steamed to improve digestibility and palatability Must declare ◦ Crude Protein, ◦ Oil, ◦ Ash, ◦ Crude fibre Ingredients are listed in descending order. No legal requirement to declare ME Ration Quality Two 17% CP Store cattle blends - which is best?: Ration 1 Maize Meal, Wheatfeed, Palm Kernel, Oatfeed, Rapeseed Meal, Sunflower Ext, Soyabean Meal Ration 2 Maize Meal, Distillers, Barley, Rapeseed Meal, Soya Hulls Ration 1: ME 11.4 Ration 2: ME 13.4 Grass, silage, straw, and meal all contain minerals Only required in small amounts Deficiency can cause nutrition disorders High producing animals most at risk Oversupply can cause toxicity Lick Buckets/Feed blocks Direct inclusion in feed rations Boluses Molasses Licks Pasture Dusting In-Line Water Dispensers Assess silage ◦ Quality ◦ Quantity Know your animals requirements Select a suitable concentrate ◦ Suitable quality ingredients ◦ Value for money