CAFRE Development Service

advertisement

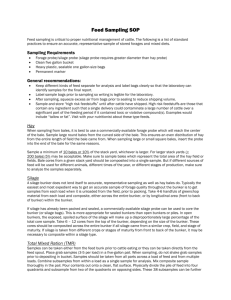

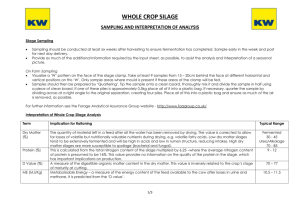

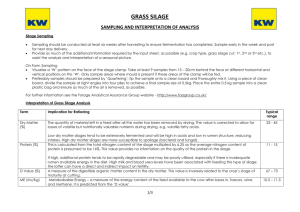

Level II Agricultural Business Operations Good quality silage is a key factor in profitable milk production Silage Production Silage Assessment Dry Matter (DM) Metabolisable Energy (ME) Crude Protein (CP) Fermentation (acidity level pH and ammonia level NH3) Dry Matter is the feed remaining after all the water has been taken out Dependent on weather and degree of wilting Ideally 25-30% Grass wilted over 30 % is more difficult to consolidate More prone to spoilage by yeasts and moulds ME measures the energy content of silage in MJ/kg DM Very high High Moderate Low >12 11.5 – 11.9 10.5 – 11.4 <10.5 CP measures the protein content of silage as a percentage of DM Very high High Moderate Low 14% 12 –14% 10 –12% <10% pH of between 3.8 and 4.2 Ammonia (% of total Nitrogen) less than 10 is desirable Good fermentation is needed to ensure the stable conversion of ensiled grass to silage Poor fermentation produces silage unpalatable to stock 1. Sward type 2. Nitrogen application 3. Stage of growth 4. Weather & grass DM 5. Chop length 6. Additives 7. Silo filling & sealing technique Perennial Ryegrass swards will produce better quality and higher D-value silage than old swards Heading date of grasses in sward will have effect on quality and D-value (early/intermediate/late) Newly reseeded swards generally produce higher quality silage Rule of thumb – allow a day for every 1kg/day (2 units) of N to grow out of grass Allow for both slurry and fertiliser N Grass analysis indicates the potential ensilability and fermentation of crop Yield increases rapidly from mid April to late June Quality decreases rapidly from mid May to mid June The stage of growth at which crop is cut will have more influence on feeding value of silage than any other factor under the farmers control 3. Stage of Growth High ME Silage 3. Stage of Growth Low ME Silage High DM silage is weather dependent Aim to harvest at 25 – 30 % DM Rapid wilting preferable (24-30 hours) Reduces effluent High DM (>30% DM) is better chopped short – approx 25mm (1 inch) – allows for better consolidation Lower DM (<25% DM) is better with longer chop length – 50 mm (2 inches) or above Aid to make good silage Inoculants are the main type ◦ Inoculants contain one or more lactic acid bacteria and promote efficient fermentation Acid additives no longer commonly used Grass placed on top by hand 50mm drainage pipe 0.125mm polythene 125 mm 600 mm Clean pit thoroughly Hang plastic side sheet to ensure good seal Spread grass over pit evenly in shallow layers 150 – 225 mm (6 – 9 inches) Roll continuously Rapid filling is best Silage effluent is highly pollutant and must be collected If stored with cattle slurry, extreme care must be taken when mixing due to increased risk of gaseous emissions Tanks must be checked regularly to prevent overflow and leakage Same principles apply as with pit silage Bales should be dense and compact Wrap as soon as possible after baling 4 - 6 layers of plastic film Wrap at the stacking area if possible Avoid excessive handling Store bales immediately after wrapping Storage in line with NIEA regulations ◦ Effluent must be collected from bales stored on concrete etc. Protect against vermin damage Calculating available silage is the first step in winter feed planning ◦ Assess silage in store ◦ Assess silage required ◦ Carry out a balance 1. Silo length 2. Silo width 3. Average silo height 4. Calculate volume (length x width x height) 10.6 m 3.3 m Volume = 10.6 X 3.3 X 22.8 22.8m 798 cubic metres (@ 20%DM) Silage Dry Matter Grass silage Silage Density Multiply volume by 18% 0.81 20% 0.77 25% 0.68 30% 0.60 10.6 m 3.3 m Volume = 10.6 X 3.3 X 22.8 798 cubic metres 798 X 0.77 = 614 t 22.8m Pit 1st Length 22.8 Width 10.6 2nd 18.9 9.1 Height Volume Factor 3.3 0.77 798 2.1 0.77 361 Tonne 614 Total 892 278 Animal Silage No. required (t/cow/mth) No mths Total (t) Milk cow Dry cow 60 20 1.5 1.2 6 6 540 144 In Calf Maiden 10 1.2 1 6 6 72 Total required (t) 756 Assess silage available against silage required Available silage = 892 tonnes Required silage = 756 tonnes In this example 136 t of silage is surplus to requirement Aim to make high quality silage Ensure correct fertiliser application Consider grass analysis pre-cutting Choose suitable cutting stage and weather Consider rapid wilt Collect and handle effluent safely Calculate quantity of silage