Lecture 1 - ITU old blogs

advertisement

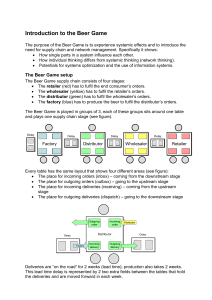

Welcome to IT Enabled Supply Chain Management Bent Steenholt Kragelund benk@itu.dk Today's Agenda • Understanding the Supply Chain • The Beer Game Course material • Textbook: Chopra, S & Meindl, P (2012) Supply Chain Management, Strategy, planning and Operation (5th edition), Pearson • Global edition of the book will work as well • Selected readings to be provided Understanding the Supply Chain What is a Supply Chain? • All stages involved, directly or indirectly, in fulfilling a customer request • Includes manufacturers, suppliers, transporters, warehouses, retailers, and customers • Within each company, the supply chain includes all functions involved in fulfilling a customer request (product development, marketing, operations, distribution, finance, customer service) What is a Supply Chain? • Customer is an integral part of the supply chain • Includes movement of products from suppliers to manufacturers to distributors and information, funds, and products in both directions • May be more accurate to use the term “supply network” or “supply web” • Typical supply chain stages: customers, retailers, distributors, manufacturers, suppliers • All stages may not be present in all supply chains (e.g., no retailer or distributor for Dell) Beer supply chain example Hops supplier Malt supplier Yeast supplier Product flow Brewery Distributor Regional Wholesaler Grocery Store Aluminum supplier Funds & information flows Can / bottle producer Glass supplier Packaging materials flow Consumer Flows in a Supply Chain – the supply web The Objective of a Supply Chain • Maximize overall value created Supply Chain Surplus = Customer Value – Supply Chain Cost The Objective of a Supply Chain • Customer the only source of revenue • Sources of cost include flows of information, products, or funds between stages of the supply chain • Effective supply chain management is the management of flows between and among supply chain stages to maximize total supply chain surplus Decision Phases of a Supply Chain Supply Chain Phase Frequency 1. Supply chain strategy or design Several years 2. Supply chain planning Quarterly / yearly 3. Supply chain operation Daily / weekly Cycle View of Supply Chain Processes • Processes in a supply chain are divided into a series of cycles, each performed at the interfaces between two successive supply chain stages Cycle View of Supply Chain Processes Push/Pull View of Supply Chains Processes in a supply chain are divided into two categories depending on whether they are executed in response to a customer order (pull reactive) or in anticipation of a customer order (push - speculative) Push/Pull View of – L.L. Bean Push/Pull View – Dell The beer game Introduction to the Beer Game • The purpose of the Beer Game is to experience systemic effects and to introduce the need for supply chain and network management. Specifically it shows: – How single parts in a system influence each other. – How individual thinking differs from systemic thinking (network thinking). – Potentials for systems optimization and the use of information systems. • The Beer Game setup – The Beer Game supply chain consists of four stages: – The retailer (orange) has to fulfil the end consumer’s orders. – The wholesaler (yellow) has to fulfil the retailer’s orders. – The distributor (green) has to fulfil the wholesaler’s orders. – The factory (blue) has to produce the beer to fulfil the distributor’s orders. • The Beer Game is played in groups of 3, each of these groups sits around one table and plays one supply chain stage (see figure). Delay Delay Factory Factory Delay Distributor Distributor Delay Wholesaler Wholesaler Retailer Retailer Table layout • Every table has the same layout that shows four different areas (see figure): – The place for incoming orders (inbox) – coming from the downstream stage – The place for outgoing orders (outbox) – going to the upstream stage – The place for incoming deliveries (receiving) – coming from the upstream stage – The place for outgoing deliveries (dispatch) – going to the downstream stage • Deliveries are “on the road” for 2 weeks (lead time); production also takes 2 weeks. This lead time delay is represented by 2 two extra fields between the tables that hold the deliveries and are moved forward in each week. Outgoing order Incoming order Distributor Distributor Delay Factory Incoming delivery Outgoing delivery Wholesaler Delay General playing procedure • The game runs in weeks and it starts in week 1. In each week, each supply chain group has to proceed with the following steps: – Receive new deliveries and update the play sheet (“incoming” and “available”). – Receive orders in the inbox and update the play sheet (“new order” and “to ship”) – Calculate the total amount that will be shipped (“your delivery”), note down the amount, and place it in a box in the dispatch area on your table. – Agree on a new order amount, note down the number, and put it in an envelope in the outbox field. • The goal – Your goal is to minimize your cost! – (Remember that you compete against the same stage in the other supply chains – retailer against retailer, distributor against distributor etc.) • There are two different kinds of cost: – Inventory cost: Items in stock cost € 0,50 per week in holding costs. – Backorder cost: If an incoming order cannot be (fully) fulfilled, items are outstanding and have to be put on “backorder” to be fulfilled in the following week(s). Each item on backorder costs € 1,00 per week. What is a backorder? • If an incoming order cannot be fully fulfilled due to a lack of available items in the inventory, items go on backorder. In this case your inventory is empty and a number of items have to appear as backorder in your play sheet. What happens in the next week? • In the following week, you will add the old backorder to the new incoming order to calculate the amount “to ship”. Again, if the available inventory is too little to fulfil the amount “to ship”, items have to be put on backorder and will cost $ 1,00 per item. Some general rules • No communication is allowed between supply chain groups, supply chain groups must not talk to each other at any time! • If stock is available, an order has to be fulfilled. • Every order has to be fulfilled, either in the current week (if enough stock is available) or in one of the next weeks (items go on backorder). • Either the inventory or the backorder, one of them is always zero (0)! Delay Delay Factory Delay Distributor Delay Wholesaler Retailer Outgoing order Incoming order Distributor Delay Factory Incoming delivery Outgoing delivery Wholesaler Delay The initial table set-up Delay D Delay Factory D D Delay Distributor D D Delay Wholesaler D D Retailer D D D D D The play-sheet Distributor Week 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Incoming Available New Order To Ship Your Delivery Backorder Inventory Your Order (Coming in from factory) (Inventory + incoming) (coming in from wholesaler) (backorder + new order) (=to ship, unless no full availability) (To ship - Your delivery) (Available - your delivery) (Your decision) 15 Cost Fill out play slips Delivery Order Step 1: Delivery IN Outgoing order Incoming order 5 Distributor Delay Incoming delivery Delay Outgoing delivery Distributor Week 0 1 2 3 Incoming Available New Order To Ship Your Delivery Backorder Inventory Your Order (Coming in from factory) (Inventory + incoming) (coming in from wholesaler) (backorder + new order) (=to ship, unless no full availability) (To ship - Your delivery) (Available - your delivery) (Your decision) 15 5 20 Cost Fill out play slips Delivery Order Step 2: Order IN Outgoing order 4 5 Incoming order Distributor Delay Incoming delivery Delay Outgoing delivery Distributor Week 0 1 2 3 Incoming Available New Order To Ship Your Delivery Backorder Inventory Your Order (Coming in from factory) (Inventory + incoming) (coming in from wholesaler) (backorder + new order) (=to ship, unless no full availability) (To ship - Your delivery) (Available - your delivery) (Your decision) 5 20 4 15 Cost Fill out play slips Delivery Order Step 3: Prepare delivery Outgoing order Incoming order 5 Distributor Delay Incoming delivery 4 Delay Outgoing delivery Distributor Week 0 1 2 3 Incoming Available New Order To Ship Your Delivery Backorder Inventory Your Order (Coming in from factory) (Inventory + incoming) (coming in from wholesaler) (backorder + new order) (=to ship, unless no full availability) (To ship - Your delivery) (Available - your delivery) (Your decision) 5 20 4 4 4 0 15 16 Cost Fill out play slips Delivery 8 4 Order Backorder Outgoing order Incoming order 5 Distributor Delay Incoming delivery Delay Outgoing delivery Distributor Incoming Available New Order To Ship Your Delivery Backorder Inventory Your Order Week (Coming in from factory) (Inventory + incoming) (coming in from wholesaler) (backorder + new order) (=to ship, unless no full availability) (To ship - Your delivery) (Available - your delivery) (Your decision) 22 23 24 25 8 4 31 23 12 25 12 25 12 23 0 2 19 0 14 Cost 205 207 Fill out play slips Delivery Order 12 23 14 Step 4: Place your order Outgoing order This is entirely your decision Keep your cost low ! Incoming order Distributor Delay Incoming delivery Delay Outgoing 4 delivery Distributor Week 0 1 2 3 Incoming Available New Order To Ship Your Delivery Backorder Inventory Your Order (Coming in from factory) (Inventory + incoming) (coming in from wholesaler) (backorder + new order) (=to ship, unless no full availability) (To ship - Your delivery) (Available - your delivery) (Your decision) 5 20 4 4 4 0 15 16 3 Cost Fill out play slips Delivery 8 4 Order 3 The initial table set-up Delay D Delay Factory D D Delay Distributor D D Delay Wholesaler D D Retailer D D D D D Between weeks - Logistics Delay D Delay Factory D D Delay Distributor D D Delay Wholesaler D D Retailer D D D D D Ready to play? • Three assistants needed • Form groups of 3 – Each group should have a Laptop / Tablet capable of running excel • Download the play-sheet from the course blog • Rename to Table-n where n is 1,2 or 3 • Open the right tab depending on your role