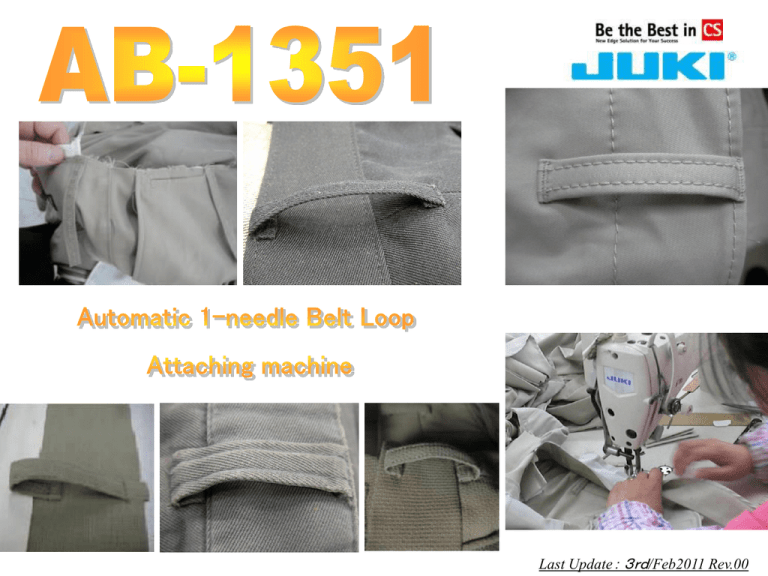

Belt-loop feeder unit

advertisement

Last Update: 3rd/Feb2011 Rev.00 Product overview What is the automatic sewing machine AB-1351? It is a JUKI's unique flexible 1-needle automatic belt loop attaching machine for sewing belt loops of consistent quality. This is the world's first 1-needle automatic belt loop attaching machine that is provided with seven different sewing patterns. Advantages of the automatic sewing machines Increased productivity Production without requiring skill Improved quality Product overview Belt-loop feeder unit Belt-loop feeder unit This unit cuts belt-loops into fixed dimensions, folds both ends inside and places them under the needle. LK1961 The belt-loops themselves are sewn in the previous process. LK1961(←LK1900A) Operation panel (IP420) This machine head sews “top and bottom bar tacks” on the belt-loops supplied by the belt-loop feeder unit. Operation panel (IP420) This panel is used to change various settings and download and/or upload data. (CompactFlash card and/or USB thumb drive can be used as a medium for inputting/outputting data.) Main features 1. The sewing machine is able to sew various types of belt-loops utilizing its seven different sewing patterns. JUKI ORIGINAL Production without requiring skill No1 No2 No3 No4 No5 No6 The original sketches are “P4 No.1 to No. 7" on the attached sheet. No7 Main features NO.1 NO.2 NO.3 NO.4 NO.5 NO.6 NO.7 ・The finished belt loops are patterns No. 5 and No. 7 illustrated in the above figures. ・The other belt loop patterns are not yet finished and need to be processed in the subsequent process. The AB-1351 is mainly intended for slacks and casual pants.This model is not suited to the sewing of belt loops on hard materials (thick denim in particular) according to the shape of belt loops. (The maximum thickness of a belt loop that can be sewn is 1.8 mm.) Main features 2-1. Improved quality and increased productivity are promised! Example: Sewing pattern No. 4 Improved quality Increased productivity In the case of manual belt-loop attaching, the operator folds the edges of the belt loops inside with his/her fingers to rough non-uniform dimensions and sews them on garments. In the case of the AB-1351, the operator is only required to place the material on the machine and Process which is press the switch to continuously sew not required. consistent-quality belt-loops. Additionally, with the AB-1351, it is not necessary to cut the belt-loop material into certain dimensions, there by contributing to labor-saving. Main features Increased productivity 2-2. To achieve increased productivity! One operator can operate to two AB1351 units at a time!! * Condition: The number of stitches (the 1st and 2nd bar tacks) 42 zigzag stitches each Also refer to "P7 attended two units." Main features JUKI ORIGINAL 3. Twin-drived belt-loop feeding mechanism The belt-loop drawing clamp and the belt-loop pushing roller operate synchronously with each other (to correct their movements in relation to each other), thereby ensuring accurate belt loop lengths even when using soft and elastic materials. (This mechanism is JUKI's unique twin-drive system.) Clamp which draws belt loops Low tension Such a high tension as to possibly damage the belt loops. Roller which pushes out belt loops Main features 4. High-performance and high precision belt loop clamp mechanism ★The belt loop feeder mechanism and the sewing machine head are assembled on the integral mounting base (unit base), thereby preventing them from slipping out of position. LK1900A machine head installing position Mono-mounting base (unit base) Belt loop feeder unit installing position Main features 5. The machine is installed with the LK-1961, which has one of the highest quality models. The machine is installed with a machine head which has been developed by modifying the highly-reliable LK1900A as the base, In the case of sewing pattern No. 4, for example, three bar tacks can be sewn with different sewing shapes, numbers of stitches, thread tensions and sewing speeds. (Maximum sewing speed: 2500 sti/min) In addition, the feed mechanism is newly controlled by an encoder to help reduce bar-tacking deformation . The “grease joint (provided as standard)" used in the oscillating rock shaft pin section can now also be used in the main shaft crank. Main features 6. User-friendly operation panel By the IP-420 operation panel, the belt loop shape or sewing pattern can be changed and the sewing positions and other sewing conditions can be programmed with ease through the operation panel. The operation panel supports 14 different languages.: Chinese(2kinds)・ English・French・ German・ Indonesian・ Italian・ Korean・ Portuguese・ Russian・ Spanish・Turkish・ Vietnamese ・Japanese Number of bar tacking patterns stored in its memory: 9 kinds . 6 Linear bar tackings :(12-, 15-, 21-, 28-, 36-, 41-stitches) 3 Zigzag bar tackings :(28-, 36-, 42-stitches) Size (X direction: 6 - 23 mm; Y direction: 0 or 1 - 3.2 mm) The maximum number of belt-loop patterns that can be stored in its memory: 99 patterns Cycle sewing: Max. 20 cycles (30 patterns per one cycle) The machine stores bar tacking shapes 200 patterns or 20,000 stitches at the maximum. It is possible to be created by the PM1 . Main features 7. The position of starting switch can be changed according to the sewing specifications. サブ テーブル Sub-tables Starting switch for sewing belt-loops on garment bodies: Starting switch for sewing belt-loops on waistbands: (Press with the right-thumb.) (Press with right-hand.) The sub-tables have to be removed. The sub-tables are to be installed. The starting switches for sewing belt-loops 「 on waistbands」 and 「on garment bodies」 are both provided as standard. Main features 8. Insert belt loops from the front side! Belt loops are to be inserted from the front side of the main body of the sewing machine. The operator is, therefore, able to visually check the belt loop state whenever necessary during sewing. 9. Oil stains on sewing products are eliminated. The machine is installed with the modified semi-dry LK1900A . The belt loop feeder unit uses a grease lubrication system (with JUKI Grease A). This means that the sewing products are no longer stained with excess oil. (A grease run-out warning sign appears on the panel .) Options 1. Other sewing gauges Narrow clamp foot : 400-91157 (for liner bar-tacking) up to belt loop width of 14mm Zigzag bar-tacking clamp foot B : 400-66686 Feed plate B:400-66744 Narrow zigzag bar-tacking clamp foot BN : 400-91156 Feed plate BN:400-75979 up to belt loop width of 14mm Part numbers of the sewing gauges have already been designated, however, some of them are out of stock in our Parts Center. (In particular, the part numbers of assemblies) So be careful. Sewing gauges: (at the time of delivery): Work clamp foot A: 400-71925 Feed plate A: 400-71906 Options 2. Manual pedal switch The work clamp is lifted/lowered by means of the foot pedal. Positioning of the garment body and fine adjustment of its position can be done with ease. The start-SW is pushed by Hand. Manual Pedal ASM:400-90639 Junction Code:400-73659 Options 3. 2-Manual pedals switch In the case of sewing patterns No4,No5andNo7. It is valid to stretch the material before sewing . First step: The right pedal controls to be lifted /lowered for [cloth clamp AR]. After The cloth clamp AR is lowered; Second step: The left pedal controls to be lifted /lowered for [cloth clamp AF]. and The start-SW is pushed by Hand. Manual Pedal ASM:GPK470010AB Junction Code 1:400-73659 Junction Code 2:400-33875 5-port Valve:PV150106000 Options 4. Bottom bar tacking cancellation switch This switch is used to cancel the bottom bar-tacking for Pattern Nos. 4, 5 and 7. This function is used in cases where the garment body has a section which is too thick to attach belt loops, for example, the center of the back body of trousers, so as to prevent sewing troubles. Cancellation SW:320-02354 Junction Code:400-43994 Screw:SM0040601SC(4pcs) Fixed Stud:HX00337000A(2pcs) Cable Clip:HX00150000B Cable Clip Screw:SL4040891SC *This SW is set under the plate. Options 5. LED marking lights Generally, one marking light, which has been provided as standard. Two marking lights are available on an additional (i.e., three marking lights can be used in total) Marking light(green-X):400-90637 Fixed Base:400-91172 Fixed Rod:400-91173 Fixed Screw:SM8050412TP(2pcs) Adjustment base:400-67813 Adjustment base Screw:SM6042002TP *Long rod for additional Lights :400-34000 Options 6. Air blow gun asm Air gun:400-44823 Air joint:PJ301065201 Coiling air tube:GSS36020000 Air tube hook:MAT81163T00 7. High-voltage transformer Part number :400-90561 This transformer is used in the high-voltage (380 V, 400 V, 415 V)areas. Options 8. Belt-loop drawer support device [Part number :400-94294] The belt-loop drawer support device pulls out, beforehand, the beltloop required for the subsequent sewing. It is particularly effective when belt-loops are wound in the shape of a drum. This device prevents any belt-loop length variation, even when using belt-loops made of elastic material. It stops showing an error message if belt loops become entangled. Comparison with competitive models ◎Major advantages of the JUKI AB1351 ① It is provided with 7-different sewing patterns to achieve higher flexibility. ②Main mechanisms have been computerized. This means that the time required for adjustment is reduced without the need for operator skill. ③ It is also easy to return the adjusted values to the previous values. ④It helps increase productivity. (One operator can attend two AB1351 units at a time.) ⑤The sewing position and belt-loop folding dimensions are accurate, thereby contributing to consistent and improved quality. The other specifications For Pattern No. 4: Electricity consumption: 190Wh Power consumption: 280VA (single-phase) 250VA (3-phase) Refer to “AB1351 catalog" Thank you for your kind attention