VERTArosta 304L - Lincoln Electric

advertisement

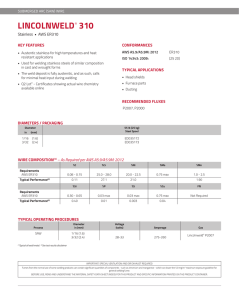

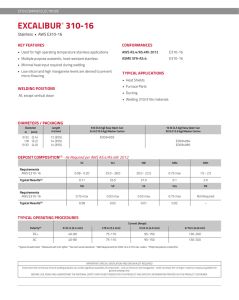

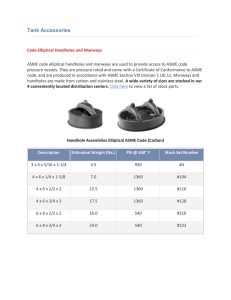

STAINLESS STEEL ELECTRODE Vertarosta® 304L CLASSIFICATION AWS A5.4 ISO 3581-A TEMPERATURE RANGE A-Nr 8 F-Nr 5 9606 FM 5 E308L-15 E 19 9 L R 2 1 Mat-Nr 1.4316 Pressurized parts :-196...+350°C Oxidation resistance :to 800°C GENERAL DESCRIPTION A rutile-basic all position stainless steel electrode for 304L or equivalent steels Specially developed for vertical down welding on DC Root pass in grooves with root opening High corrosion resistance in oxidizing environments WELDING POSITIONS (ISO/ASME) CURRENT TYPE DC + PG/3Gd APPROVALS TÜV DB + + CHEMICAL COMPOSITION (W%), TYPICAL, ALL WELD METAL C Mn Si Cr Ni FN (acc.WRC 1992) 0.02 0.8 0.7 20.0 9.8 4-10 MECHANICAL PROPERTIES, TYPICAL, ALL WELD METAL Required: AWS A5.4 ISO 3581-A Typical values Condition 0.2% Proof strength (N/mm2) Tensile strength (N/mm2) Elongation (%) +20°C -20°C -120°C AW not required min. 320 440 min. 520 min. 510 600 min. 35 min. 30 40 not required not required 70 50 40 Impact ISO-V(J) PACKAGING AND AVAILABLE SIZES Carton + PE foil Identification Diameter (mm) Length (mm) 2.5 300 3.2 300 Pieces / unit Net weight/unit (kg) 190 2.9 130 3.1 Imprint: 308L-15 / VERTAROSTA 304 L Tip Color: grey Vertarosta® 304L: rev. C-EN24-01/02/16 All information in this data sheet is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.eu for any udpated information. Fumes: Material Safety Data Sheets (MSDS) are available on our website. STAINLESS STEEL ELECTRODE Vertarosta® 304L EXAMPLES OF MATERIALS TO BE WELDED Steel gradesEN 10088-1/-2EN 10213-4Mat. NrASTM/ACI A240/A312/A351 Extra low carbon (C <0.03%) UNS X2CrNi19-11 1.4306(TP)304L S30403 CF-3 J92500 X2CrNiN18-10 1.4311 (TP)304LN S30453 302,304 S30400 Medium carbon (C >0.03%) X4CrNi18-10 1.4301 (TP)304 S30409 GX5CrNi19-10 1.4308 CF 8J92600 Ti-, Nb stabilized X6CrNiTi18-10 1.4541 (TP)321 S32100 (TP)321H S32109 X6CrNiNb18-10 1.4550 (TP)347 S34700 (TP)347H S34709 1.4552CF-8C J92710 GX5CrNiNb19-10 CALCULATION DATA Sizes Current Diam. x length Current range type (mm) (A) 2.5 x 300 60-70 DC+ 3.2 x 300 80-110 DC+ Arc time Energy Dep. rate - per electrode at max. current (S)* E(kJ) H(kg/h) 44 65 0.81 51 117 1.2 *Stub end 35mm WELDING PARAMETERS, OPTIMUM FILL PASSES Diameter (mm) Welding positions PG/3Gdown 2.5 3.2 www.lincolnelectric.eu 70A 100A Weight/ 1000 pcs (kg) 15.0 23.5 Electrodes/ kg electrodes/ kg weldmetal kg weldmetal 1/N B 101 1.52 59 1.39