Response Surface Methodology

advertisement

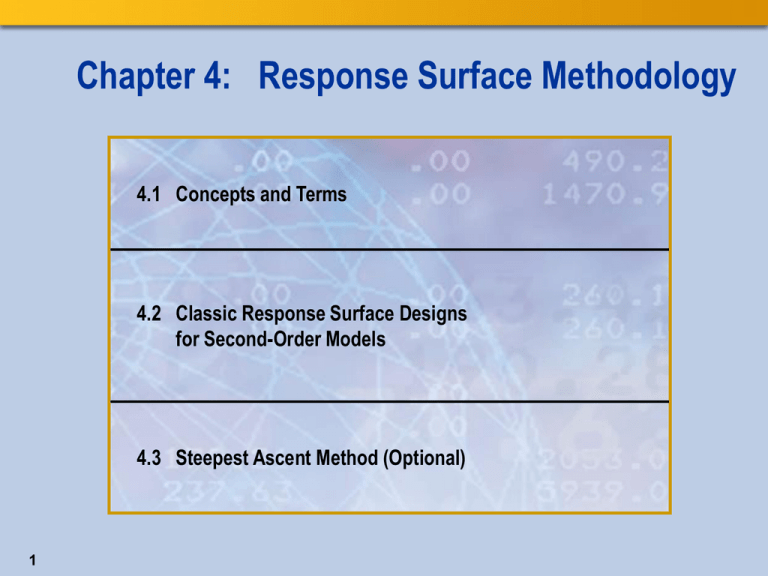

Chapter 4: Response Surface Methodology

4.1 Concepts and Terms

4.2 Classic Response Surface Designs

for Second-Order Models

4.3 Steepest Ascent Method (Optional)

1

Chapter 4: Response Surface Methodology

4.1 Concepts and Terms

4.2 Classic Response Surface Designs

for Second-Order Models

4.3 Steepest Ascent Method (Optional)

2

Objectives

3

Understand response surface methodology and its

sequential nature.

Distinguish among different kinds of optima.

Illustrate different types of surfaces and relate those

surfaces to model equations.

Response Surface Methodology

4

Response surface methodology (RSM) uses various

statistical, graphical, and mathematical techniques to

develop, improve, or optimize a process.

The most frequent applications of RSM are in the

industrial area, where several predictor variables are

used to predict some performance measure or quality

characteristic of a product or process.

Sequential Nature of RSM

5

You used designed experiments to determine what

factors are important in determining the qualities of

your product or the results of your process.

Now you want to find factor settings or a factor region

that optimize your response or responses.

Finding these factor settings or factor region is an

iterative process that utilizes designs discussed in the

previous chapters and designs to be discussed in this

chapter.

New Purpose Requires New Designs

At this point, you need more detailed information than the

screening design could give you; optimum conditions are

difficult to find using only screening designs. For this, you

need more data in order to add new effects to your model.

The design you select and the new data points you add

depend on the model you want to fit.

To estimate

linear parameters, you could use a two-level fractional

factorial design of resolution ≥ 3.

cross-product parameters, you could use a fractional

factorial design of resolution ≥ 5.

quadratic parameters, data for at least 3 levels of each

factor is required.

6

The Number of Levels

Model adequacy requires testing (m+1) levels of a factor

with order m polynomial effects.

Linear effects, m = 1, require two factor levels.

Quadratic effects, m = 2, require three factor levels.

Effects greater than second-order, m ≥ 3, are unusual.

You can avoid a large number of levels by restricting

the factor ranges.

7

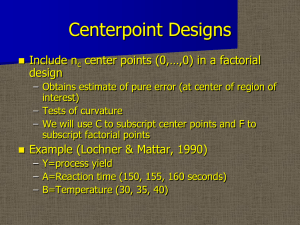

Center Points

Center points

provide a third level to support a quadratic model

are positioned symmetrically between the ends of the

test range {-1, 0, +1}

are a common element in response surface designs

are focused replication to estimate pure error

add to screening designs to provide additional

information.

8

9

4.01 Multiple Answer Poll

Which of the following statements are true about center

points?

a. They are positioned halfway between the low and high

settings.

b. They are coded as 0.

c. They are commonly found in response surface

designs.

d. They are used to estimate pure error.

10

4.01 Multiple Answer Poll – Correct Answers

Which of the following statements are true about center

points?

a. They are positioned halfway between the low and high

settings.

b. They are coded as 0.

c. They are commonly found in response surface

designs.

d. They are used to estimate pure error.

11

General Optimum Response

You might have a general objective in mind for your

response.

More is better (maximum).

Less is better (minimum).

Target is better (range of response values).

12

Specific Acceptable Response Values

You might have a specific objective for your goal. For

example:

Yield should be at least 90%.

Impurity must be less than 5 mg/L.

Final acidity is best at 4.5 0.2 pH.

13

Satisfy More Than One Goal

You might have more than one response, and each

response has a unique goal.

Some responses have more demanding specifications

than other responses.

Some responses are more important than other

responses.

The best factor settings are a trade off of all of the

response goals.

14

15

4.02 Multiple Choice Poll

What is the most common goal for the processes at your

business?

a. To maximize

b. To minimize

c. To hit a target

16

Design Under Factor Constraints

You might also have a factor with specifications, or a

constraint. Such specifications or constraints might:

Account for physical limitations.

Minimize costs or safety risks.

Manage inventory or control cost.

You want to satisfy this constraint when you find the

optimum settings.

17

The Response Surface and its Model

Your response usually depends on more than one factor.

The shape of the response as a function of two or more

factors defines a surface.

You want to explore the surface for the optimum

response without testing every possible point.

This true response model that describes the surface is

usually unknown.

A smooth interpolating function is usually used, and it

generally includes quadratic and interaction effects.

Y 0 i X i i j X i X j ii X

18

2

i

RSM Models For Two Factors

Screening

y=0 + 1x1 + 2x2 + 12x1x2 +

Steepest ascent

y=0 + 1x1 + 2x2 +

Optimization

y=0 + 1x1 + 2x2 + 12x1x2 + 11x1 + 22x2 +

2

19

2

Good Design

A good design is both effective and efficient.

An effective design enables you to obtain sufficient

data to fit an interpolating model that provides

unbiased predictions with sufficient precision.

An efficient design enables you to obtain the most

precise estimates for a given budget on the number of

runs.

20

Shape of the Response

This demonstration illustrates the concepts discussed

previously.

21

22

4.03 Quiz

Match each surface type with its graph.

A.

B.

C.

D.

23

E.

1.

2.

3.

4.

5.

Planar Surface

Quadratic Surface

Saddle Surface

Ridge Surface

Twisted Surface

4.03 Quiz – Correct Answer

Match each surface type with its graph.

A.

B.

C.

D.

E.

1-A, 2-B, 3-D, 4-C, 5-E

24

1.

2.

3.

4.

5.

Planar Surface

Quadratic Surface

Saddle Surface

Ridge Surface

Twisted Surface

25

Chapter 4: Response Surface Methodology

4.1 Concepts and Terms

4.2 Classic Response Surface Designs

for Second-Order Models

4.3 Steepest Ascent Method (Optional)

26

Objectives

27

Understand properties of Box-Behnken and Central

Composite designs.

Generate and analyze a Box-Behnken design.

Generate and analyze a Central Composite design.

Box-Behnken Design

The Box-Behnken design

incorporates three levels (coded –1, 0, +1)

has points that are vertices of a polygon and

equidistant from the center

avoids extreme points

(for example, [+1, +1, +1])

does not utilize a screening run

is the smallest classic response surface design for

fewer than five factors

has uniform blocks: each level of each factor is in each

block an equal number of times and the center points

are evenly divided among the blocks.

28

Box-Behnken Design Example

29

The objective of an experiment is to reduce the

unpleasant odor of a chemical product. The response

variable is Odor, and it is believed that a secondorder model is required.

The factors are temperature (Temp) with a range of

40-120, gas and liquid ratio (GL Ratio) with a

range of .2-.7, and packing height (Height) with a

range of 2-6.

Box-Behnken Design Example

30

There are 3 continuous factors (Temp, GL Ratio,

and Height). For a Box-Behnken design, there will be

15 runs: 12 to examine all possible combinations of low

and high for each pair of factors (with the third factor at

the center) and 3 center points.

The plot shows the position of the design points.

Box-Behnken Design

This demonstration illustrates the concepts discussed

previously.

31

32

4.04 Quiz

Match each graph with its name.

A.

C.

33

B.

1. Surface Plot

2. Contour Plot

3. Prediction Profiler

4.04 Quiz – Correct Answer

Match each graph with its name.

A.

C.

B.

1. Surface Plot

2. Contour Plot

3. Prediction Profiler

1-B, 2-C, 3-A

34

Central Composite Design

X

X

X

X

X

X

35

X

X

The CCD design

incorporates five levels

(coded –α,-1, 0,+1,+α)

shares screening runs

has axial points (±α) for

one factor and 0 for all

other factors

is the largest factorial

design for 3 factors and

the smallest for 5 or

more factors

has points that form a

cube plus a star

Central Composite Design Example

36

Recall the experiment to determine which factors are

important to determine Seal Strength for a bread

wrapper. The experimenter decides to run a CCD to

understand the shape of the response surface and to

find an optimum setting for these factors.

The factors are % Polyethylene with a range of

85-95, Cooling Temperature with a range of

120-140, and Sealing Temperature with a

range of 220-240.

Central Composite Design Example

37

There are 3 continuous factors (% Polyethylene,

Cooling Temperature, and Sealing

Temperature). For a CCD design with uniform

precision, there will be 20 runs: 8 from the 23 design,

6 axial points, and 6 center points.

The plot shows the position of the design points.

Central Composite Design

This demonstration illustrates the concepts discussed

previously.

38

39

4.05 Multiple Answer Poll

Which of the following are properties of the Box-Behnken

design?

a. Avoids extreme design points

b. Incorporates axial points

c. Is rotatable or nearly rotatable

d. Supports screening runs

e. Is the smallest classic response surface design for

fewer than 5 factors

f. Is a spherical design

40

4.05 Multiple Answer Poll – Correct Answers

Which of the following are properties of the Box-Behnken

design?

a. Avoids extreme design points

b. Incorporates axial points

c. Is rotatable or nearly rotatable

d. Supports screening runs

e. Is the smallest classic response surface design for

fewer than 5 factors

f. Is a spherical design

41

Exercise

This exercise reinforces the concepts discussed

previously.

42

43

4.06 Quiz

The Prediction Profiler output from the exercise is below.

Examine the solutions for the three variables. Which

variable’s solution is problematic? Why?

44

4.06 Quiz – Correct Answer

The Prediction Profiler output from the exercise is below.

Examine the solutions for the three variables. Which

variable’s solution is problematic? Why?

Distance – the solution is problematic because distance cannot be

negative. JMP gave this answer because there was no constraint on

Distance.

45

46

Chapter 4: Response Surface Methodology

4.1 Concepts and Terms

4.2 Classic Response Surface Designs

for Second-Order Models

4.3 Steepest Ascent Method (Optional)

47

Objectives

48

Understand the procedures of the method of steepest

ascent to find an optimum.

Design a sequence of experiments using the method

of steepest ascent.

Stages to Find Optimum

Three stages depict the usual sequence to study a process.

1. Screen important effects: this tells you what factors

are important in the first region of optimization.

2. Optimize factor settings: this is only possible if your

current region of investigation contains the optimum you

seek.

3. Verify optimum conditions: this is done after an optimum

is found.

An intermediate step between steps 1 and 2 might be

necessary to find the right region of optimization.

49

Eyes On the Optimum

50

Visualize the Response

51

Your screening experiment will sample some region

in the possible factor space. This region is anchored

in space by its center; the coded level for every factor

at this point is zero.

Without prior knowledge, the range of factor settings

and the multitude of potential factors result in a large

space to search.

The complexity of your response goals might further

reduce the likelihood that the initial region will contain

the optimum.

Graphs Are Useful Searching Tools

Use graphs to visualize the response during your search.

Prediction Profile plot (1D) is a slice of a contour or a

surface plot.

Contour plot (2D) is a topographical map of the

response surface.

Surface plot (3D) of the response shows the shape of

the response from various angles.

52

Method of Steepest Ascent

The method of steepest ascent

is an iterative process that uses multifactor screening

designs and center points

is based on a search strategy (choose direction and

step size)

accommodates minimizing, maximizing, or targeting

goals.

53

Linear Screening Models

54

The original design space does not contain the

optimum.

If you are not close to the optimum, then quadratic

effects should be small: think of the side of a smooth

mountain.

A linear screening model provides the trajectory

toward the goal.

Steps in the Search Process

55

Screen for the important factors and assess the

location of the optimum.

Determine the direction and step size towards the

optimum from the screening model.

Take uniform steps, i for each factor xi, while the

response improves.

Continue stepping along until there is no further

increase or until a decrease in the response is

observed.

Check the direction and model lack of fit.

Determine the Direction

Consider an example of a two-factor case without

interaction.

The linear model parameters define the path of steepest

ascent.

Y = 0 + 1X1 + 2X2

1 and 2 indicate the change in Y for a one-unit

change in coded X.

The vector {1, 2} points to the optimum from the

origin.

56

Step Size

57

You want to take the largest steps possible to reach

the optimum in the fewest steps, but too large of a

step size might mean that you miss the optimum.

Use engineering and scientific knowledge to weigh

the possibilities, and take some risk.

Replicate if necessary to detect a significant

improvement.

After a Stop

When the response either decreases or no longer

increases, it is either because the maximum response is

in the vicinity or because it is not in the vicinity, but

instead you are on a ridge or at a saddle point.

Therefore you have to decide if you want to stay here and

find the optimum or determine a new path and step size to

continue to search.

To decide, first design a two-level screening experiment

and include center points (and shift the initial origin to the

best stop point), fit a new first-order model, and test for a

lack of fit.

58

Continue or Stay

59

Continue the search if there is no detectable or

significant lack of fit. The maximum response is not in

this region, so you need to determine the new

direction and step size.

Stay if the lack of fit test based on the center points

suggests a quadratic effect in the current region. In

this case, design an experiment to ensure model

adequacy for a response surface model. A central

composite design is a good choice for this sequence.

Caveats for Steepest Ascent

60

The same principles apply if the goal is a minimum

response but in an opposite sense. This is called the

path of steepest descent.

The goal might instead be a target. Stop this search

when the range of the response includes the target.

The method of steepest ascent is aggressive. Smaller

adjustments can be used safely to maintain an

optimum response. This method is known as

evolutionary operation (EVOP).

Path of Steepest Ascent for Yield Example

61

A chemical engineer wants to maximize the Yield

of a process.

Two factors have been determined as important:

Reaction Time and Reaction

Temperature.

Currently the process is completed in about 35

minutes at a temperature of about 155 degrees.

Method of Steepest Ascent

This demonstration illustrates the concepts discussed

previously.

62

63