•

Optimization problems using

excel solver

McGraw-Hill/Irwin

Copyright © 2009 by The McGraw-Hill Companies, Inc. All rights reserved.

LAB 3

Linear Programming Using the

Excel Solver

2A-3

OBJECTIVES

• Linear Programming Basics

• A Maximization Problem

• A Minimization Problem

2A-4

Linear Programming Essential Conditions

• Is used in problems where we have

limited resources or constrained

resources that we wish to allocate

• The model must have an explicit

objective (function)

– Generally maximizing profit or

minimizing costs subject to resourcebased, or other, constraints

2A-5

Linear Programming Essential Conditions (Continued)

• Limited Resources to allocate

• Linearity is a requirement of the model

in both objective function and

constraints

• Homogeneity of products produced

(i.e., products must the identical) and

all hours of labor used are assumed

equally productive

• Divisibility assumes products and

resources divisible (i.e., permit

fractional values if need be)

2A-6

Common Applications

•

•

•

•

•

•

•

Aggregate sales and operations planning

Service/manufacturing productivity analysis

Product planning

Product routing

Vehicle/crew scheduling

Process control

Inventory control

2A-7

Objective Function

Maximize (or Minimize) Z = C1X1 + C2X2 + ... + CnXn

• Cj is a constant that describes the

rate of contribution to costs or

profit of (Xj) units being produced

• Z is the total cost or profit from

the given number of units being

produced

2A-8

Constraints

A11X1 + A12X2 + ... + A1nXnB1

A21X1 + A22X2 + ... + A2nXn B2

:

:

AM1X1 + AM2X2 + ... + AMnXn=BM

• Aij are resource requirements for each of

the related (Xj) decision variables

• Bi are the available resource

requirements

• Note that the direction of the inequalities

can be all or a combination of , , or =

linear mathematical expressions

2A-9

Non-Negativity Requirement

X1,X2, …, Xn 0

• All linear programming model

formulations require their decision

variables to be non-negative

• While these non-negativity

requirements take the form of a

constraint, they are considered a

mathematical requirement to

complete the formulation of an LP

model

2A-10

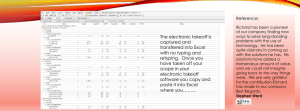

Excel solver

• The Excel Solver is a tool for solving linear

and nonlinear optimization problems.

– For linear optimization problems: Simplex method,

with branch and bound algorithm for integer

design variables.

– For nonlinear optimization problems: Generalized

reduced gradient method.

• Solver is an Add-In for Microsoft Excel

which can solve optimization problems,

including multiple constraint problems.

• Launching the Excel Solver:

Start the Excel program.

Tools > Solver…

2A-11

Installing Excel solver

• On Excel Menu,

choose

– Tools

• Add-Ins...

– Put a Check

in the Box Next

to ‘Solver Add-in’

2A-12

Using Excel solver

• On Excel Menu,

choose

– Tools

• Solver

– This brings

up the Solver

Parameters

box which

will be

discussed next.

2A-13

Excel solver

2A-14

Excel solver

Using the Excel Solver: (…continued)

Add: (adding a new constraint)

Cell Reference:

Address of design variable.

Choose type of constraint:

or = or or int (integer) or bin (binary).

Constraint:

Value of constraint (if applicable).

Options:

Assume Non-Negative (if all design variables are nonnegative) > OK.

OK or Add (to add another constraint)

2A-15

An Example of a Maximization Problem

LawnGrow Manufacturing Company must determine the unit

mix of its commercial riding mower products to be

produced next year. The company produces two product

lines, the Max and the Multimax. The average profit is $400

for each Max and $800 for each Multimax. Fabrication hours

and assembly hours are limited resources. There is a

maximum of 5,000 hours of fabrication capacity available

per month (each Max requires 3 hours and each Multimax

requires 5 hours). There is a maximum of 3,000 hours of

assembly capacity available per month (each Max requires 1

hour and each Multimax requires 4 hours). Question: How

many units of each riding mower should be produced each

month in order to maximize profit?

Now let’s formula this problem as an LP model…

2A-16

The Objective Function

If we define the Max and Multimax products as the two

decision variables X1 and X2, and since we want to

maximize profit, we can state the objective function as

follows:

Maximize Z = 400X1 + 800 X 2

Where

Z = the monthly profit from Max and Multimax

X1 = the number of Max produced each month

X 2 = the number of Multimax produced each month

2A-17

Constraints

Given the resource information below from the problem:

Max (X1)

Required Time/Unit

3

1

Multimax (X2)

Required Time/Unit

5

4

Available Time/Month

5,000

3,000

Fab

Assy

We can now state the constraints and non-negativity

requirements as:

3X1 + 5X2 5,000

(Fab.)

X1 + 4X2 3,000

(Assy.)

X1 , X 2

0

(Non- negativity)

Note that the inequalities are less-than-or-equal since

the time resources represent the total available

resources for production

2A-18

Solution

Produce 715 Max and 571 Multimax per

month

for a profit of $742,800

2A-19

The Excel Solver Formulation

2A-20

An Example of a Minimization Problem

HiTech Metal Company is developing a plan for buying

scrap metal for its operations. HiTech receives scrap

metal from two sources, Hasbeen Industries and

Gentro Scrap in daily shipments using large trucks.

Each truckload of scrap from Hasbeen yields 1.5 tons

of zinc and 1 ton of lead at a cost of $15,000. Each

truckload of scrap from Gentro yields 1 ton of zinc and

3 tons of lead at a cost of $18,000. HiTech requires at

least 6 tons of zinc and at least 10 tons of lead per day.

Question: How many truckloads of scrap should be

purchased per day from each source in order to

minimize scrap metal costs to HiTech?

Now let’s formula this problem as an LP model…

2A-21

The Objective Function

If we define the Has been truckloads and the Gentro

truckloads as the two decision variables X1 and X2, and

since we want to minimize cost, we can state the

objective function as follows:

Minimize Z = 15,000 X1 + 18,000 X2

Where

Z=

daily scrap cost

X1 = truckloads from Hasbeen

X2 = truckloads from Gentro

Hasbeen

Gentro

2A-22

Constraints

Given the demand information below from the problem:

Hasbeen (X1)

Tons

1.5

1

Gentro (X2)

Tons

1

3

Min Tons

6

10

Zinc

Lead

We can now state the constraints and non-negativity

requirements as:

1.5X1 +

X2

> 6(Zinc/tons)

X1

3X2

> 10(Lead/tons)

+

X1, X2

> 0(Non-negativity)

Note that the

inequalities are

greater-than-orequal since the

demand information

represents the

minimum necessary

for production.

2A-23

Solution

Order 2.29 truckloads from Hasbeen and 2.57

truckloads from Gentro for daily delivery. The daily

cost will be $80,610.

Note: Do you see why in this solution that

“integer” linear programming methodologies

can have useful applications in industry?

2A-24

The Excel Solver solution

2A-25

Question

Find x1, x2, x3, x4, y1, y2, y3, y4 to

maximize

f = 10x1+ 6.5x2+ 6x3+ 5x4 2y1+

5.5y2+ 5y3+ 4y4

subject to

x1+ y1 = 25

x2+ y2 = 45

x3+ y3 = 50

x4+ y4 = 60

x1+ x2+ x3+ x4 50

y1+ y2+ y3+ y4 1000

x1, x2, x3, x4, y1, y2, y3, y4 0.

2A-26

Answer

Using the Excel Solver:

Design variables:

A1 = x1, A2 = x2, A3 = x3, A4 = x4

B1 = y1, B2 = y2, B3 = y3, B4 = y4

Objective function:

C1 =

10*A1+6.5*A2+6*A3+5*A42*B1+5.5*B2+5*B3

+4*B4

Constraints:

D1 = A1+B1, D2 = A2+B2,

D3 = A3+B3,

D4 = A4+B4

D5 = A1+A2+A3+A4, D6 = B1+B2+B3+B4

2A-27

Answer

• (…continued)

Set Target Cell: C1

Equal To: Max

By Changing Cells: A1 to B4

Subject to the Constraints: Add

D1 = 25

Add

D2 = 45

Add

D3 = 50

Add

D4 = 60

Add

D5 <= 50

Add

D6 <= 1000

OK

Options > Assume Non-Negative > OK

Solve

Keep Solver Solution > OK

2A-28

Answer

• (…continued)

Solutions in A1 to A4 and B1 to B4:

(x1, x2, x3, x4) = (25, 0, 10, 15)

(y1, y2, y3, y4) = (0, 45, 40, 45)

Maximum profit in C1 = 1012.5

Note that the solution is not unique. Verify that

another solution is given by

(x1, x2, x3, x4) = (25, 0, 0, 25)

(y1, y2, y3, y4) = (0, 45, 50, 35)

2A-29

End