Proper Storage and Shelf Life of Concentrated Brewing

advertisement

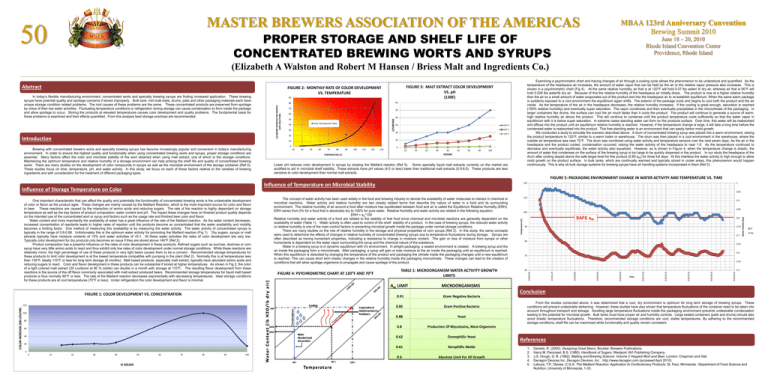

50 MASTER BREWERS ASSOCIATION OF THE AMERICAS MBAA 123rd Anniversary Convention PROPER STORAGE AND SHELF LIFE OF CONCENTRATED BREWING WORTS AND SYRUPS June 18 – 20, 2010 Rhode Island Convention Center Providence, Rhode Island Brewing Summit 2010 (Elizabeth A Walston and Robert M Hansen / Briess Malt and Ingredients Co.) Abstract Introduction 90 60 80 70 50 60 LOVIBOND 50 Color Development Rate 40 30 40 30 pH 6 pH 5 20 pH 4 20 10 10 Brewing with concentrated brewers worts and specialty brewing syrups has become increasingly popular and convenient in today’s manufacturing environment. In order to ensure the highest quality and functionality when using concentrated brewing worts and syrups, proper storage conditions are essential. Many factors affect the color and microbial stability of the wort obtained when using malt extract, one of which is the storage conditions. Maintaining the optimum temperature and relative humidity of a storage environment can help prolong the shelf life and quality of concentrated brewing worts. There are many studies on the development of color compounds in syrups as well as the microbial environment of the storage container (Ref 5). These studies focus on time, temperature, pH, and water activity. In this study, we focus on each of these factors relative to the varieties of brewing ingredients and with consideration for the treatment of different packaging types. FIGURE 3: MALT EXTRACT COLOR DEVELOPMENT VS. pH (130F) FIGURE 2: MONTHLY RATE OF COLOR DEVELOPMENT VS. TEMPERATURE LOVIBOND INCREASE PER MONTH (10% SOLUTION) In today’s flexible manufacturing environment, concentrated worts and specialty brewing syrups are finding increased application. These brewing syrups have potential quality and spoilage concerns if stored improperly. Bulk tank, mini bulk totes, drums, pails and other packaging materials each have unique storage condition related problems. The root causes of these problems are the same. These concentrated products are preserved from spoilage by virtue of their low water activities. Fluctuating temperature conditions or refrigeration during storage can cause condensation to form inside the package and allow spoilage to occur. Storing the products at elevated temperatures causes color development and quality problems. The fundamental basis for these problems is examined and their effects quantified. From this analysis best storage practices are recommended. Examining a psychrometric chart and tracing changes of air through a cooling cycle allows the phenomenon to be understood and quantified. As the temperature of the headspace air increases, the amount of water vapor that can be held by the air or the relative vapor pressure also increases. This is shown in a psychrometric chart (Fig 4). At the same relative humidity, air that is at 120°F will hold 0.07 lbs water/ lb dry air, whereas air that is 90°F will hold 0.026 lbs water/lb dry air. Because of this the relative humidity of the headspace air initially drops. The product is now at a higher relative humidity than the air so a small amount of water evaporates out of the product and into the headspace air to re-establish equilibrium. When the same warm package is suddenly exposed to a cool environment the equilibrium again shifts. The exterior of the package cools and begins to cool both the product and the air inside. As the temperature of the air in the headspace decreases, the relative humidity increases. If the cooling is great enough, saturation is reached (100% relative humidity) and eventually super saturation. The vapor condenses and then eventually precipitates in the microclimate of the packaging. In larger containers like drums, the surface can cool the air much faster than it cools the product. The product will continue to generate a source of warm, high relative humidity air above the product. This will continue to condense until the product temperature cools sufficiently so that the water vapor in equilibrium with it is below super saturation. In extreme cases standing water can form on the products surface. Over time, this water will be reabsorbed and diffuse into the product until an equilibrium relative humidity is reached. However, if the temperature change is large, it will take a long time before the condensed water is reabsorbed into the product. This free standing water is an environment that can easily harbor mold growth. We conducted a study to simulate the scenario described above. A drum of concentrated brewing syrup was placed into a warm environment, raising the product temperature to 120°F, similar to a warm trailer or warehouse. The drum was then placed in a cool environment in the warehouse, where the outside air temperature was near 70°F. The drum was monitored using water activity and temperature sensors over the next seven days. As the air in the headspace and the product cooled, condensation occurred, raising the water activity of the headspace to near 1.0. As the temperature continued to decrease and eventually equilibrate, the water activity also equalized. However, as is shown in Figure 4, when the temperature change is drastic, the amount of water that condenses on the surface of the brewing syrup is too large to be quickly dispersed in the product. In our study the headspace of the drum after cooling stayed above the safe target level for this product (0.80 aW) for three full days. At this interface the water activity is high enough to allow mold growth on the product surface. In bulk tanks, which are continually warmed and typically stored in cooler areas, this phenomenon would happen continuously. This is why all bulk storage systems for brewing syrups have air handling systems incorporated in them (Ref 2) . 0 30 40 50 60 70 80 90 100 110 120 130 0 10 20 30 40 40 50 60 80 100 HOURS TEMPERATURE (F) Lower pH reduces color development in syrups by slowing the Maillard reaction (Ref 5). Some specialty liquid malt extracts currently on the market are acidified to aid in microbial shelf stability. These extracts have pH values (4.0 or less) lower than traditional malt extracts (5.0-6.0). These products are less sensitive to color development than normal malt extracts. FIGURE 5: PACKAGING ENVIRONMENT CHANGE IN WATER ACTIVITY AND TEMPERATURE VS. TIME Influence of Storage Temperature on Color 1 0.95 Water Activity (Aw) Temperature (F) 0.7 0.6 70 0.55 60 0.5 4/15/2010 0:00 Time 4/14/2010 0:00 Gram Positive Bacteria 0.88 Yeast 0.8 Production Of Mycotoxins, Most Organisms 0.62 Osmophillic Yeast 0.61 Xerophillic Molds 0.6 Absolute Limit For All Growth 0 10 20 30 40 50 % SOLIDS 60 70 80 90 100 Aw 0.65 From the studies conducted above, it was determined that a cool, dry environment is optimum for long term storage of brewing syrups. These conditions will prevent undesirable darkening. However, these studies have also shown that temperature fluctuations of the container need to be taken into account throughout transport and storage. Avoiding large temperature fluctuations inside the packaging environment prevents undesirable condensation leading to the potential for microbial growth. Bulk tanks must have proper air and humidity controls. Large sealed containers (pails and drums) should also avoid drastic temperature fluctuations. Therefore, recommended storage conditions are cool, stable temperatures. By adhering to the recommended storage conditions, shelf life can be maximized while functionality and quality remain consistent. References 20 0 ºF 80 4/13/2010 0:00 0.86 80 40 0.75 Conclusion 100 60 90 4/12/2010 0:00 Gram Negative Bacteria 0.8 4/11/2010 0:00 0.91 SAFE aW 4/10/2010 0:00 MICROORGANISMS 0.85 100 4/9/2010 0:00 AW LIMIT 0.9 4/8/2010 0:00 120 FIGURE 4: PSYCHROMETRIC CHART AT 120°F AND 70°F TABLE 1: MICROORGANISM WATER ACTIVITY GROWTH LIMITS 110 4/7/2010 0:00 FIGURE 1: COLOR DEVELOPMENT VS. CONCENTRATION The concept of water activity has been used widely in the food and brewing industry to denote the availability of water molecules to interact in chemical or microbial reactions. Water activity and relative humidity are two closely related terms that describe the nature of water in a food and its surrounding environment. The relative humidity of air around a food after moisture has equilibrated between food and air is called the Equilibrium Relative Humidity (ERH). ERH varies from 0% for a food that is absolutely dry to 100% for pure water. Relative Humidity and water activity are related in the following equation: ERH = aw*100 Relative humidity and water activity of a food are related to the stability of that food since chemical and microbial reactions are generally dependent on the availability of water (Table 1). Water activity is often used to control of the shelf stability of a product. In the case of brewing syrups, the reduced water activity or relative humidity is one of the main control factors in preventing microbial growth inside the package under normal storage conditions. There are many studies on the role of relative humidity in the storage and physical properties of corn syrups (Ref 2). In this study, the same concepts were used to determine the effects of changes in relative humidity of concentrated brewing syrups due to temperature fluctuations during storage. Syrups are often described as having humectant properties, indicating a resistance to change in moisture content. The gain or loss of moisture from syrups or other humectants is dependent on the water vapor surrounding the syrup and the chemical nature of the substance. Water in a brewing syrup is in dynamic equilibrium with it’s environment. In airtight packaging, a sealed environment is created. A brewing syrup and the air inside the packaging form a microclimate. After packaging, a syrup will gain or lose moisture to the air inside the packaging until an equilibrium is reached. When this equilibrium is disturbed by changing the temperature of the product and packaging the climate inside the packaging changes until a new equilibrium is reached. This can cause short term drastic changes in the relative humidity inside the packaging microclimate. These changes can lead to the creation of conditions that will allow spoilage organisms to propagate and cause spoilage of the product. 4/6/2010 0:00 One important characteristic that can affect the quality and potentially the functionality of concentrated brewing worts is the undesirable development of color or flavor as the product ages. These changes are mainly caused by the Maillard Reaction, which is the most important source for color and flavor in beer. These reactions are caused by the interaction of amino acids and reducing sugars. The rate of the reaction is highly dependant on storage temperature as well as the key factors of product composition: water content and pH. The impact these changes have on finished product quality depends on the intended use of the concentrated wort or syrup and factors such as the usage rate and finished beer color and flavor. Water content and more importantly the availability of water has a great influence of the rate of the Maillard reaction. As the water content decreases, increased concentration of reactants leads to higher rates of reaction until the products become so concentrated that the water availability and mobility becomes a limiting factor. One method of measuring this availability is by measuring the water activity. The water activity of concentrated syrups is typically in the range of 0.6-0.88. Unfortunately this is the optimum water activity for promoting the Maillard reaction (Fig 1). Dry sugars, syrups or malt extracts typically have moisture contents of <3% and water activities of <0.1. At these water activities the rates of color development are very low. Typically color development for dry products only becomes an issue if they are stored above 140°F (Ref 2). Product composition has a powerful influence on the rates of color development in these products. Refined sugars such as sucrose, dextrose or corn syrup have very little amino acids to react and thus exhibit only low rates of color development under normal storage conditions. While these reactions are relatively minor, the high percentage of use of these products in very light beers causes them to be a concern. Recommended storage temperatures for these products to limit color development is at the lowest temperature compatible with pumping in the plant (Ref 2). Normally this is at temperatures less than 130°F, ideally 110°F or less for long term storage (6 months). Malt based products, especially malt extract, typically have abundant amino acids and reducing sugars to react. Color and flavor development in these products can be substantial if stored at higher temperatures. As shown in Fig 2, the color of a light colored malt extract (30 Lovibond at 80 % solids) can double in a month with storage at 110°F. The resulting flavor development from these reactions is the source of the off flavor commonly associated with malt extract produced beers. Recommended storage temperatures for liquid malt based products is thus normally 90°F or less. The rate of the Maillard reaction decreases exponentially with decreasing temperatures. Ideal storage conditions for these products are at cool temperatures (70°F or less). Under refrigeration the color development and flavor is minimal. COLOR INCREASE (DB LOV/HR) 120 Influence of Temperature on Microbial Stability 1. 2. 3. 4. 5. Daniels, R. (2000). Designing Great Beers. Boulder: Brewers Publications. Harry M. Pancoast, B.S. (1980). Handbook of Sugars. Westport: AVI Publishing Company. J.S. Hough, D. B. (1982). Malting and Brewing Science: Volume 2 Hopped Wort and Beer. London: Chapman and Hall. Decagon Devices Inc. Decagon Devices, Inc. . http://www.decagon.com (accessed April 2010) Labuza, T.P., Davies, C.G.A. The Maillard Reaction: Application to Confectionery Products. St. Paul, Minnesota : Department of Food Science and Nutrition, University of Minnesota, 1-33.