Customer - Suffolk Resilience

advertisement

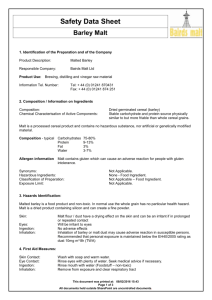

Muntons presentation to BC Forum 5th September 2013 Sarah Phillips – Head of Procurement The facts A brief history of Muntons plc 1921 Muntons was incorporated as a company 1948 Moved to Stowmarket 1964 Expanded to Bridlington 2007 Singapore office opened 2009 US company formed based in Seattle 2010 Office opened in Bangkok What we do 180,000 20 At Bridlington and Stowmarket we make around 180,000 tonnes of malt We are in the world’s top 20 manufacturers of malt 45,000 Enough for 2340 million pints of beer! We produce around 45,000 tonnes of malted ingredients, the largest in Europe and arguably the world. Local Supply – Global Customers 66 Agents and Distributors globally supplying 62 countries Greenest maltster in the world – lowest carbon malt commitment Delivering to customers from 1kg packs to 29 tonne bulk Product range and industry scope Diversification of product and customer into sustainable growth areas through innovation Malt Focused on brewing and distilling markets Malted Ingredients Focused on diverse markets • Food • Bakery • Beverages • Confectionary • Pharmaceuticals • Micro Brewery • Home beer and wine Central Services Division • Financial services • Information systems support • Compliance management • Human resources. Investing Our People Investing ininour people Investment in quality staff Investment in training Investment in relationships with customers and suppliers Corporate Social Responsibility involve all stakeholders Community • Customer • Services • Employees • Principle enshrined in law • It is not old fashioned philanthropy/donations to good causes • It is the contribution of business to the Government’s sustainable development goals • Currently voluntary, taking into account economic social and environmental impacts of companies’ operations – over and above compliance • Year round responsibility • Something we have done for a while – but not formalized • Involvement to continue in key areas: - Environment - Education - Employees - Local community. We like to do business the right way Striving to constantly improve standards of quality in all we do, showing consideration for our environment and respecting business relationships with both customers and suppliers ISO 9001:2008 Quality Management System ISO 14001:2004 Environment Management System ISO 22000:2005 Food Safety Management System ISO50001:2011 Energy Management System BRC Global Standard Food ver 5 X American Institute of Baking (Milled products) All cereal raw materials sourced from accredited farms All products assured Muntons Malt are GM free “Assured UK Malt” Suppliers Organic Certification (Stowmarket site) Muntons: Building a Sustainable Future Sustainability This is the common objective that links all aspects of Muntons business activities. An ongoing process that will ensure our goods are supplied in an economical, environmental and socially responsible way, now and into the future. Where has Sustainability taken us? 8 years ago working with consortium on water recycling 5 years ago first carbon footprint calculation: now 5th iteration Identification of carbon hotspots driven capital programme: energy, recycling Involvement in government and supply chain advisory groups Wider supply chain involvement downstream Focus on practical solutions that have environmental and financial benefit Muntons are helping farmers save money and reduce the supply chain carbon footprint Factors driving supply chain complexity Innovation Volatility Risk Technology Increasingly complex & changing markets Stakeholder demands Position in Supply Chain Farmers & Merchants Customers Consumers Manufacturers Muntons Manufacturer & Wholesaler Retailers Distributors Agents buildingourbusinesstherightway Supply chain challenges Lead time gap Construction and Engineering Automotive Europe Automotive USA and Retail Time horizon Source Make Deliver Lead Time Gap Customer Accepted Lead Time Order Penetration point Muntons Development of Procurement & Supply Chain Management Dedicated Grain Supply Chain Team. Centralised Non-Grain Procurement Team. Managing barley risk Supplier relationships, working closely with farmers and merchants Long term supply agreements to secure supply and manage price volatility Collaboration with customers through long term supply agreements backing off risk Educating customers on barley risk Supply Chain Collaboration Agrarfrost, Agroterra, Aviko, Barilla , CIO Parma, CocaCola, Danone, Farm Frites, Fonterra, General Mills, Heineken, Kraft, Kellogg, Lamb Weston Meijer, McCain, McDonald's, Nestlé, Pepsico, Unilever Logistics is CORE 1 or 2 suppliers per mode of transport, transactional relationships primarily driven by cost and turnover Low level understanding of each others’ businesses and supply chains Internal inefficiencies driving up costs Reduce transport costs, “missed tricks” and untapped potential benefit from economies of scale Our chosen strategy is LLP To reduce operating costs (e.g. Transport) Remove non-value added activities, share benefits of improvements Improve customer service performance Supplier management 1300 live vendors, focus on critical and high value ones, longer term supply agreements 700 direct materials purchased from over 100 vendors going into approximately 750 finished product lines sold to nearly 600 customers globally Stringent supplier approval process (quality, food safety, sustainability, ethical, CSR , capability, business continuity plans/management system) – visits, audits) SEDEX membership Continual assessment of supplier performance, complaints & corrective actions (quality systems), feedback to suppliers and exchange of information Overriding objectives Develop sustainable supply chains which our customers want to lock into Develop strategic supplier partnerships which we want to lock into Act as a catalyst for supply chain discussions across many diverse industries