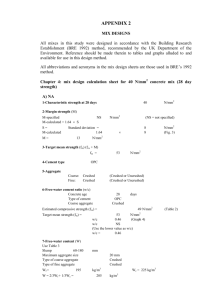

8-ACI Design

advertisement

ACI Concrete Mix Design N.C. DEPARTMENT OF TRANSPORTATION MATERIALS AND TESTS UNIT CONCRETE CERTIFICATION SCHOOL Design Process Pg 78 Determine the quantities of fine and coarse aggregate necessary to provide concrete meeting the requirement of he specifications using the absolute volume basis. Submit mix designs for each class of concrete to be used in the work. Design Submit mix designs in terms of saturated surface dry weights on M&T form 312U at least 35 days prior to using the proposed mix. Adjust batch proportions to compensate for surface moisture contained in the aggregates at the time of batching. Design Changes in the saturated surface dry mix proportions will not be permitted unless revised mix designs have been submitted to the Engineer and have been determined to be acceptable for use. Design Accompany Form 312U with a listing of laboratory test results of aggregate gradation, air content, slump, and compressive strength. List the compressive strength of at least three 6” x 12” or 4” x 8” cylinders at the age of 7 and 28 days. Design Pg 79 When the combination of materials is such that the compressive strength and/ or workable slump can not be obtained at the minimum specified cement content with the maximum allowable water-cement ratio, increase the cement at non cost to the Department by whatever amount is required without exceeding the allowable W/C ratio. Design Acceptance of the mix design does not relieve the Contractor of the responsibility to furnish an end product meeting specifications requirements. Pg 80 ACI Concrete Mix Design The NC DOH has adopted the ACI absolute volume method of design and requires this method be used in the design of all concrete mixes. Remember: Absolute Volume= Weight / (SG x 62.4) Mix Design Process Pg 81 Before calculations can begin on a concrete mix design, some info has to be supplied. • Class of concrete to be designed • Type of placement, vibrated or non vibrated • Fine aggregates • Specific Gravity • Fineness Modulus Design • Coarse aggregates • • • • Nominal maximum size of aggregate Specific Gravity Dry-rodded unit weight Rounded or angular aggregate • N.C. Specifications • Min. Cement content, W/C ratio, air content, Nom. Maximum aggregate size ACI Table 5.3.6 Pg 85 Volume of Coarse Aggregate Per Unit of Volume of Concrete Nominal Max size of aggregat e Volume of Dry-rodded coarse aggregate* per unit Volume of Concrete for Different Fineness Moduli of Sand Fineness Modulus of Sand inches 2.30 2.40 2.50 2.60 2.70 2.80 2.90 3.00 3/8” 0.51 0.50 0.49 0.48 0.47 0.46 0.45 0.44 ½” 0.60 0.59 0.58 0.57 0.56 0.55 0.54 0.53 ¾” 0.67 0.66 0.65 0.64 0.63 0.62 0.61 0.60 1” 0.72 0.71 0.70 0.69 0.68 0.67 0.66 0.65 1 ½” 0.76 0.75 0.74 0.73 0.72 0.71 0.70 0.69 2” 0.79 0.78 0.77 0.76 0.75 0.74 0.73 0.72 3” 0.83 0.82 0.81 0.80 0.79 0.78 0.77 0.76 5 Basic Ingredients Pg 87 Cement Fine Aggregate Coarse Aggregate Water Air The combined total absolute volume should be 27 cubic feet Mix Design Worksheets Fine Aggregate Data Coarse Aggregate Data ACI Table 5.3.6 Table 1000-1 Example, pg 83 Using information provided, design a NCDOT Class A mix. Pg 83 Min. Cement Max W/C ratio Agg. Shape Nom Max size Air Content Slump FM of sand SG sand SG stone D.R. UW 564 pounds .488 rounded ¾“ 6 3” 2.75 2.63 2.86 104.0 pcf Cement Cement amount is determined from Table 1000-1 based on the class of concrete specified, vibrated or non vibrated. Max W/C Ratio Maximum water cement ratio is based on aggregate shape. Air entrained concrete has a different ratio than non air entrained concrete. Water The amount of cement and the W/C ratio are used to determine the quantity of water. Aggregate The aggregate data sheets are used to get the FM of he sand, SG of sand and stone, and the dry rodded unit weight of the stone. Cement Pg 84 564____ = 2.87 cuft/cuyd 315 x 62.4 Water 564 x .488 = 275 = 33.0 gallons 8.33 33.0 = 4.40 cu.ft./ cu.yd. 7.5 Air .06 x 27 cu.ft. = 1.62 cu.ft./cu.yd. Because air does not have a SG, the 6% volume that is displace by air is used. Coarse Aggregate Pg 85 Use ACI Table 5.3.6 to determine the % of the concrete mix that should be coarse aggregate. Use the nominal maximum size aggregate and the fineness modulus of the sand to determine the %. Use ACI Table 5.3.6 to determine that 62% of the mix must be dry rodded coarse aggregate. .062 x 27 cu.ft. = 16.74 cu.ft/cu.yd. 16.74 x 104.0 pcf = 1741 Lbs of stone 1741 / (2.86 x 62.4) = 9.76 cu.ft./ cu.yd Pg 87 Fine Aggregate Total the absolute volumes of the other materials Cement Water Air Stone Total Design 564 Lbs 33.0 gals 6% 1741Lbs Abs Vol 2.87 4.40 1.62 9.76 18.65 Determine the volume of the fine aggregate 27.00 cu.ft. - 18.65 cu.ft 8.35 cu.ft. weight of sand required is 8.35 cu ft x 2.63 x 62.4 = 1370 Lbs ACI Worksheet Example Fine Agg Coarse Agg Table 5.3.6 Table 1000-1 Problem 1 Class AAvib AE Sand-Lilesville Stone-Matthews Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Pg 105 Problem 2 Class Avib AE Sand-Emery Pit Stone-Kannapolis Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Pg 106 Problem 3 Class AAvib AE Sand-Great Pit Stone-Crabtree Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Problem 4 Class Bnonvib AE Sand-Boone Q Stone-Mt Airy Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Problem 5 Class AvibAE Sand-Johnsonville Pit Stone-Greystone Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Problem 6 Class BvibAE Sand-Candor Pit Stone-North Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Problem 7 Class AAvibAE Sand-Pageland Q Stone-Matthews Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Problem 8 Class BnonvibAE Sand-Lilesville Pit Stone-Elkin Q Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Pg 97 Mix Designs Using Fly Ash Fly Ash may be substituted for Portland cement up to 20% by weight of the required cement. Substitute at the rate of at least 1.2 pounds of Fly Ash per pound of cement. Maximum Water Cementitious Material Ratio Table Class Round Angular Concrete Aggregate Aggregate AA .366 .410 A .469 .512 B .469 .545 Example pg 91 Design a Class A Fly Ash mix using the South McDowell Q # 57 stone and Rocky River sand. Substitute Fly Ash for 20% of the cement. Use 1.5 gallons less than the max water. Cement Multiply 20% times the 564 pounds of cement for Class A to get 112.8 pounds. Subtract from original cement pounds to get 451 pounds. (564 X .20) - 113 = 451 pounds of cement Fly Ash Multiply 112.8 times 1.2 to get 135 pounds of Fly Ash. 112.8 X 1.2 = 135 pounds of Fly Ash Water Multiply max W/C ratio of .512 times the total amount of cementitious material. (.512 X 586) / 8.33 - 1.5 = 34.5 gallons – The design process for the remaining components remains the same. Problem 9 Fly Ash Class AAvibAE Fly Ash Sand-Great Pit Stone-Greystone Q 20% replacement SG Fly Ash 2.26 Fine agg wkst Coarse agg wkst Table 5.3.1 Table 1000-1 Fly Ash wkst Problem 9 Cement and Fly Ash quantity Cement 639 x .20 = 128 639 -128 = 511 Lbs Cement Fly Ash 18 x 1.2 = 154 Lbs Fly Ash