CP504Lecture_05_OK

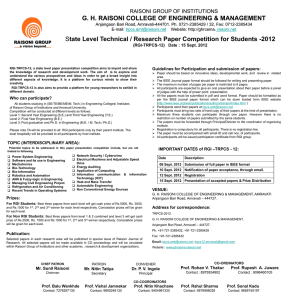

advertisement

CP504 – Lecture 5 Enzyme kinetics and associated reactor design: Immobilized enzymes enzyme mobility gets restricted in a fixed space Prof. R. Shanthini 30 Sept 2011 1 Immobilized enzyme reactor (example) Recycle packed column reactor Prof. R. Shanthini 30 Sept 2011 2 Advantages of immobilized enzymes: - Easy separation from reaction mixture, providing the ability to control reaction times and minimize the enzymes lost in the product - Re-use of enzymes for many reaction cycles, lowering the total production cost of enzyme mediated reactions - Ability of enzymes to provide pure products - Possible provision of a better environment for enzyme activity Prof. R. Shanthini 30 Sept 2011 3 Disadvantages of immobilized enzymes: - Problem in diffusional mass transfer - Enzyme leakage into solution - Reduced enzyme activity and stability - Lack of controls on micro environmental conditions Prof. R. Shanthini 30 Sept 2011 4 Methods of immobilization 1) Entrapment Immobilization 2) Surface Immobilization 3) Cross-linking Prof. R. Shanthini 30 Sept 2011 5 1) Entrapment Immobilization It is the physical enclosure of enzymes in a small space. - Matrix entrapment (matrices used are polysaccharides, proteins, polymeric materials, activated carbon, porous ceramic and so on) - Membrane entrapment (microcapsulation or trapped between thin, semi-permeable membranes) Prof. R. Shanthini 30 Sept 2011 6 1) Entrapment Immobilization Advantage is enzyme is retained. Disadvantages are - substrate need to diffuse in to access enzyme and product need to diffuse out - reduced enzyme activity and enzyme stability owing to the lack of control of micro environmental conditions Prof. R. Shanthini 30 Sept 2011 7 2) Surface Immobilization - Physical adsorption (Carriers are silica, carbon nanotube, cellulose, and so on; easily desorbed; simple and cheap; enzyme activity unaffected ) - Ionic binding (Carriers are polysaccharides and synthetic polymers having ion-exchange centers) - Covalent binding (Carriers are polymers containing amino, carboxyl, hydroxyl, or phenolic groups; loss of enzyme activity; strong binding of enzymes) Prof. R. Shanthini 30 Sept 2011 8 Methods of immobilization Prof. R. Shanthini 30 Sept 2011 9 3) Cross linking is to cross link enzyme molecules with each other using agents such as glutaraldehyde. Prof. R. Shanthini 30 Sept 2011 10 Comparison between the methods Adsorption Covalent coupling Entrapment Membrane confinement Simple Difficult Difficult Simple Low High Moderate High Variable Strong Weak Strong Yes No Yes No Applicability Wide Selective Wide Very wide Running problems High Low High High Matrix effects Yes Yes Yes No Large diffusional barriers No No Yes Yes Microbial protection No No Yes Yes Characteristics Preparation Cost Binding force Enzyme leakage Prof. R. Shanthini 30 Sept 2011 11 Immobilized enzyme reactor (example) Recycle packed column reactor - Allow the reactor to operate at high fluid velocities Prof. R. Shanthini 30 Sept 2011 12 Immobilized enzyme reactor (example) Fluidized bed reactor - A high viscosity substrate solution - A gaseous substrate or product in a continuous reaction system - Care must be taken to avoid the destruction and decomposition of immobilized enzymes Prof. R. Shanthini 30 Sept 2011 13 Immobilized enzyme reactor (example) - An immobilized enzyme tends to decompose upon physical stirring. Continuous stirred tank reactor - The batch system is generally suitable for the production of rather small amounts of chemicals. Prof. R. Shanthini 30 Sept 2011 14 Effect of mass-transfer resistance in immobilized enzyme systems: Mass transfer resistance is present - due to the large particle size of the immobilized enzymes - due to the inclusion of enzymes in polymeric matrix Prof. R. Shanthini 30 Sept 2011 15 Effect of mass-transfer resistance in immobilized enzyme systems: Mass transfer resistance are divided into the following: - External mass transfer resistance (during transfer of substrate from the bulk liquid to the relatively unmixed liquid film surrounding the immobilized enzyme and during diffusion through the relatively unmixed liquid film) - Intra-particle mass transfer resistance (during diffusion from the surface of the particle to the active site of the enzyme in an inert support) Prof. R. Shanthini 30 Sept 2011 16 External mass-transfer resistance: Assumption: - Enzymes are evenly distributed on the surface of a nonporous support material. - All enzyme molecules are equally active. - Substrate diffuses through a thin liquid film surrounding the support surface to reach the reactive surface. - The process of immobilization has not altered the enzyme structure and the M-M kinetic parameters (rmax, KM) are unaltered. Prof. R. Shanthini 30 Sept 2011 Ss C Ss Sb CSb Enzyme Enzyme Liquid Filmfilm Thickness, L Liquid thickness, 17 L External mass-transfer resistance: Diffusional mass transfer across the liquid film: Ss C Ss JS = kL (CSb – CSs) kL Sb CSb liquid mass transfer coefficient (cm/s) CSb substrate concentration in the bulk solution (mol/cm3) CSs substrate concentration at the immobilized enzyme surface (mol/cm3) Prof. R. Shanthini 30 Sept 2011 Enzyme Enzyme Liquid Filmfilm Thickness, L Liquid thickness, 18 L External mass-transfer resistance: At steady state, the reaction rate is equal to the mass-transfer rate: JS = kL (CSb – CSs) = Sb CSb rmax CSs KM + CSs rmax maximum reaction rate per unit of external surface area (e.g. mol/cm2.s) KM is the M-M kinetic constant (e.g. mol/cm3) Prof. R. Shanthini 30 Sept 2011 Ss C Ss Enzyme Enzyme Liquid Filmfilm Thickness, L Liquid thickness, 19 L Example 3.4 in Shuler & Kargi: Consider a system where a flat sheet of polymer coated with enzyme is placed in a stirred beaker. The intrinsic maximum reaction rate of the enzyme is 6 x 10-6 mols/s.mg enzyme. The amount of enzyme bound to the surface has been determined to be maximum 1 x 10-4 mg enzyme/cm2 of support. In solution, the value of KM has been determined to be 2 x 10-3 mol/l. The mass-transfer coefficient can be estimated from standard correlations for stirred vessels. We assume in this case a very poorly mixed system where kL = 4.3 x 10-5 cm/s. What is the reaction rate, when the bulk concentration of the substrate (CSb) is (a) 7 x 10-3 mol/l and (b) 1 x 10-2 mol/l? Prof. R. Shanthini 30 Sept 2011 20 Solution to Example 3.4 in Shuler & Kargi: Data provided: rmax = 6 x 10-6 x 1 x 10-4 mols/s.cm2 = 6 x 10-10 mols/s.cm2 KM = 2 x 10-3 mol/l = 2 x 10-6 mol/cm3 kL = 4.3 x 10-5 cm/s CSb = 7 x 10-3 mol/l OR 1 x 10-2 mol/l = 7 x 10-6 mol/cm3 OR 1 x 10-5 mol/cm3 Equation to be solved: JS = kL (CSb – CSs) + rmax CSs KM + CSs where CSs should be solved for, which can then be used to calculate JS. Prof. R. Shanthini 30 Sept 2011 21 Solution to Example 3.4 in Shuler & Kargi: J_S for part (a) J_S for part (b) r_S 2 J_S or r_S (mol/s.cm ) 6.E-10 5.E-10 4.E-10 3.E-10 2.E-10 1.E-10 0.E+00 0 Prof. R. Shanthini 30 Sept 2011 0.002 0.004 0.006 C_Ss (mol/l) 0.008 0.01 22 External mass-transfer resistance: JS = kL (CSb – CSs) = rmax CSs KM + CSs Non dimensionalizing the above equation, we get 1 - C’Ss NDa = β C’Ss 1 + β C’Ss where C’Ss = CSs / CSb NDa β Prof. R. Shanthini 30 Sept 2011 = rmax / (kL CSb ) = CSb / KM is the Damköhler number is the dimensionless substrate concentration 23 Damköhler number (NDa) NDa = Maximum rate of reaction Maximum rate of diffusion = rmax kL CSb If NDa >> 1, rate of diffusion is slow and therefore the limiting mechanism rp = JS = kL (CSb – CSs) If NDa << 1, rate of reaction is slow and therefore the limiting mechanism rmax CSs rp = KM + CSs If NDa = 1, rates of diffusion and reaction are comparable. Prof. R. Shanthini 30 Sept 2011 24 Effectiveness factor (η) η= actual reaction rate rate if not slowed by diffusion β C’Ss rmax CSs η= KM + CSs rmax CSb KM + CSb = 1 + β C’Ss β 1+β Effectiveness factor is a function of β and C’Ss Prof. R. Shanthini 30 Sept 2011 25 Internal mass transfer resistance: Assumption: - Enzyme are uniformly distributed in spherical support particle. - Substrate diffuses through the tortuous pathway among pores to reach the enzyme - Substrate reacts with enzyme on the pore surface -Diffusion and reaction are simultaneous - Reaction kinetics are M-M kinetics Prof. R. Shanthini 30 Sept 2011 CSs CSr2 26 Diffusion effects in enzymes immobilized in a porous matrix: Under internal diffusion limitations, the rate per unit volume is expressed in terms of the effectiveness factor as follows: rmax’ CSs rS = η KM + CSs rmax’ KM CSs η maximum reaction rate per volume of the support M-M constant substrate concentration on the surface of the support effectiveness factor Prof. R. Shanthini 30 Sept 2011 27 Diffusion effects in enzymes immobilized in a porous matrix: Definition of the effectiveness factor η η= reaction rate with intra-particle diffusion limitation reaction rate without diffusion limitation For η < 1, the conversion is diffusion limited For η = 1, the conversion is limited by the reaction rate Effectiveness factor is a function of β and C’Ss Prof. R. Shanthini 30 Sept 2011 28 Diffusion effects in enzymes immobilized in a porous matrix: β η φ Theoretical relationship between the effectiveness factor (η) and first-order Thiele’s modulus (φ) for a spherical porous immobilized particle for various values of β, where β is the substrate concentration at the surface divided by M-M constant. Prof. R. Shanthini 30 Sept 2011 29 Diffusion effects in enzymes immobilized in a porous matrix: Relationship of effectiveness factor (η) with the size of immobilized enzyme particle and enzyme loading Prof. R. Shanthini 30 Sept 2011 30