AWLC14-VEP-saeki

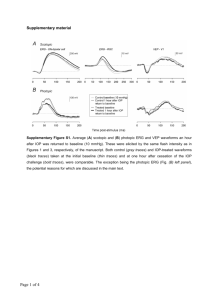

advertisement

VEP studies at STF/KEK T. Saeki (KEK) 15 May 2014 AWLC2014 at FNAL Electro-polishing (EP) process • EP is thought to be the best final surface-polishing process of ILC 9-cell cavity to achieve high-gradient specification of ILC. • EP is also most complicated/costy surface-preparation process in the cavity mass-production of ILC. • The current standard EP method is called “horizontal EP process”, where a cavity is set up in a horizontal posture and the cavity is rotated during the EP process. • In order to achieve simpler and more cost-effective EP process, ”vertical EP process” is studied in many laboratories in the world, where a cavity is set up in a vertical and fixed posture. Horizontal EP (HEP) / Vertical EP (VEP) Rotation of cavity in HEP process. (HEP setup at KEK-STF) EP electrolyte is fully filled. EP electrolyte is half filled. Turning the EP-bed for draining No rotation of cavity in VEP process. (VEP setup at Saclay) Horizontal EP / Vertical EP • Horizontal EP (HEP) Asia: KEK-STF Europe: DESY, Saclay, RI, Zanon US: FNAL, ANL, Jlab, AES • Vertical EP (VEP) Asia: KEK / Marui Galvanizing Co. Ltd. Europe: Saclay US: Cornell, JLab I will present these activities. Vertical electro-polishing (VEP) ・No need of large space ・No need of cavity rotation ・No need of horizontal-vertical conversion system More suitable for mass production Development of retractable wing-shape cathode in collaboration with Marui Co. Ltd. EP electrolyte is circulated to remove hydrogen gas and for low temperature. The retractable-wing cathode to realize uniform flow of electrolyte and uniform distribution of electric current. Flow direction •Side View Rotation of cathode Al Acid bath •Top View Pump •Opened •Retracted Marui Galvanizing Co. Ltd. named the cathode “Ninja”, which is registered as a trade name. VEP experiments with “Ninja” cathode 1, VEP experiments with two single-cell cavities for vertical tests ・To optimize VEP condition and evaluate acceleration gradient 2, VEP experiments with one coupon single-cell cavity ・To investigate the relationship between VEP condition (temperature, current, etc.) and surface state after VEP (roughness, removal thickness etc.) ・To achieve more uniform VEP 3, VEP experiments with one 9-cell cavity for vertical tests ・To optimize VEP condition and evaluate acceleration gradient ・To develop the VEP mass production system VEP experiment with single-cell cavity VEP setup single-cell cavity (-) Spot Cooler Motor Nb Single Cell Cavity (+) Pump 1 VEP condition (an example) Pump 2 Acid Container Heat Exchanger Schematic view of VEP setup EP solution: H2SO4(98%):HF(55%)=9:1 Voltage: 9V Flow rate: 5L/min Cathode rotation speed: 5rpm EP duration: 90min Flow direction: Bottom to top Development of retractable wing-shape cathode in collaboration with Marui Co. Ltd. The hydrogen gas generated during EP process is the most difficult problem. Lower side: smooth. Upper side: stripe by bubbles. Flaws observed after VEP with inadequate parameters (voltage, temp, flow rate, etc...): - Stripe on surface (due to bubbles) - Rough surface These problems should be overcome. VEP experiment with single-cell cavity 35 60 60 50 50 40 40 30 30 20 20 10 10 Lower beam pipe Near the equator (lower) Near the equator (upper) Upper beam pipe Inlet of EP solution Outlet of EP solution 29 27 25 23 21 19 17 15 0 0 20 40 60 80 100 Current density Voltage 0 0 20 40 60 80 100 Time(min) Time( min) Logged data (Temperature-time) Upper cup 40 30 25 20 15 10 5 0 1 2 3 4 5 6 Point of measurement Polishing amount (μm) 40 Lower cup 40 1~8 35 Polishing amount (μm) After VEP Logged data (Voltage, Current density-time) Polishing amount (μm) Before VEP Voltage( V) Temperature( ℃) 31 Current density( mA/cm 2 ) 33 7 8 9~16 35 30 25 20 15 10 5 0 91 2 10 17~24 35 1 30 25 2 20 3 15 4 5 171 2 18 3 4 5 6 19 20 21 22 Point of measurement 7 23 8 24 5 10 18 7 15 16 7 15 8 16 Upper 19 20 21 14 8 In the next step, we would like to do vertical test and know the acceleration gradient of VEP’ed cavity. 17 12 13 6 Removal thickness 9 11 10 0 Inner surface of cavity 3 4 5 6 11 12 13 14 Point of measurement 22 23 24 Lower Plan of VEP + VT with single-cell cavity in collaboration with CEA Saclay Vertical test (VT) result (37 MV/m) at CEA Saclay before transportation to KEK /Marui VEP + VT plan with 1AC3 cavity 1AC3 cavity sent from CEA Saclay to KEK / Marui. ・Inner surface inspection etc. at Marui Inner surface at Marui (Digital camera) Marui VEP with “Ninja” ・Transportation back to CEA Saclay. ・Vertical Test (VT) at CEA Saclay 1AC3 cavity will be VEP’ed at Marui and will be sent back to CEA Saclay for VT. Inner surface at Marui (Endoscope) VEP experiments with coupon single-cell cavity Nb coupons (6 points) ・EP current ・Temperature ・Surface roughness ・Removal thickness ・Impurities can be investigated. Coupon cavity (with 6 Nb coupons and transparent windows) Transparent window (4 points) ・State of bubbles ・State of cathode can be seen during VEP process. VEP condition (an example) VEP setup EP solution: H2SO4(98%):HF(55%)=9:1 Voltage: 9–11V Flow rate: 5L/min Rotation speed: 1rpm EP time: 150min Flow direction: Bottom to top Schematic for a coupon single-cell cavity with a VEP cathode “Ninja” Cathode wing Upper window Coupon Window Coupon Lower window Cathode rod VEP experiment with coupon single-cell cavity Temperature (After 120min) : Coupon position 20 Upper Temperature (℃) 22 24 26 28 Current density (After 120min) Removal thickness Current density (mA/cm2) 5 10 15 20 25 30 35 30 Top beam pipe Top beam pipe Top iris Surface roughness Ra Removal thickness (μm) 30 50 70 90 Surface roughness Ra (μm) 0 110 Top beam pipe Top beam pipe Top iris Top iris Top iris Equator left Equator left Equator left Equator left Equator right Equator right Equator right Equator right Bottom iris Bottom iris Bottom iris Bottom iris Bottom beam pipe Bottom beam pipe Bottom beam pipe 0.2 0.4 0.6 Bottom beam pipe lower (Temperature near coupon) ・Temperature The influence of bubble hitting from wings? (Now under investigation) Equator is highest ・Current density ・Removal thickness ・Surface roughness Ra Bubbles Largest at top iris To achieve more uniform VEP, we need to develop how to control bubbles. EP solution flow VEP experiment with 9-cell cavity VEP setup for 9-cell cavity Degassing tank 9-cell cavity VEP condition (an example) EP solution tank Water Waste liquid Schematic view of VEP setup EP solution: H2SO4(98%):HF(55%)=9:1 Voltage: 7-9V Flow rate: 10L/min Rotation speed: 1rpm EP time: 90min Flow direction: Bottom to top VEP experiment with 9-cell cavity 50 U1E U1LI 45 U2UI 42 U2E 43 Temperature (℃) 44 45 46 47 0 Average removal thickness (μm) 5 10 15 20 25 30 U2LI 40 U3UI U3E 1 U3LI U4UI Temperature (℃ ) 35 Upper 1 Upper U4E U4LI U5UI 30 U5E 2 2 3 3 4 4 U5LI U6UI U6E 25 U6LI U7UI U7E 20 U7LI U8UI U8E 15 U8LI sol 10 0 20 40 60 80 100 120 140 RT 160 Time (min) Logged data (Temperature-time) 5 5 6 6 7 7 8 8 15 25 20 10 Voltage (V) Current density (mA/cm2) 30 Cell No. U9E Cell position U9UI 15 10 5 5 9 Lower 9 Temperature in EP tank 0 0 0 20 40 60 Time (min) 80 Lower Total average 18.2μm 100 Logged data (Voltage, Current density-time) Average temperature of each cell (After 60min) Average removal thickness of each cell VEP experiments with 9-cell cavity Inner surface inspection Temperature (℃ ) Point of measurment Position U5UI U5E U5LI U6UI U6E U6LI U7UI U7E U7LI U8UI U8E U8LI U9UI U9E Temperature of each parts (after 60min) 70 U4E U4LI 60 U4UI 50 U3E U3LI 40 U3UI 30 U2E U2LI 20 0 U1LI U2UI 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 U1E 10 50 49 48 47 46 45 44 43 42 41 40 Removal thickness( mm) From upper side 5th cell upper iris Removal thickness of each parts 5th cell lower iris 5th cell equator 5th cell – 6th cell We need more optimization (voltage, flow rate, temperature etc.) →After optimization, we would like to perform vertical test of 9-cell cavity COI: Center-of-Innovation Building at KEK 2012 supplementary-budget: model facility for ILC assembly & Testing STF building COI building construction area COI building 17 COI: Center-of-Innovation Building Vertical-EP As a model facility for ILC assembly & Testing Clean-room He Cryogenics EP(vertical-EP) Cavity Testing(4-cavities-test) Cryomodule Assembly(cantilever) Cryomodule Testing Cantilever18 New VEP setup delivered for COI building Cathode motor Cathode insertion tool. EP bed Manufacturer is MHI EP bed is used both for HEP and VEP (2 ways). This enables the direct comparison of HEP and VEP processes. Summary • KEK started the R&D of Vertical EP (VEP) process in collaboration with Marui Galvanizing Co. Ltd. • Special cathode “Ninja” is developed by Marui Galvanizing Co. Ltd. for VEP process. The “Ninja” cathode has retractablewings which realize uniform flow of electrolyte and uniform distribution of electric current. • VEP experiments are performed with single-cell cavities, single-cell coupon cavity, and 9-cell cavities to optimize the parameters. • Single-cell cavity “1AC3” provided by CEA Saclay will be VEP’ed with “Ninja” cathode and the cavity will be VT’ed at CEA Saclay. • New COI building will be equipped with VEP/HEP compatible setup by MHI, which was already delivered to KEK. The setup will be installed into the new COI building in 2015.