PPT

advertisement

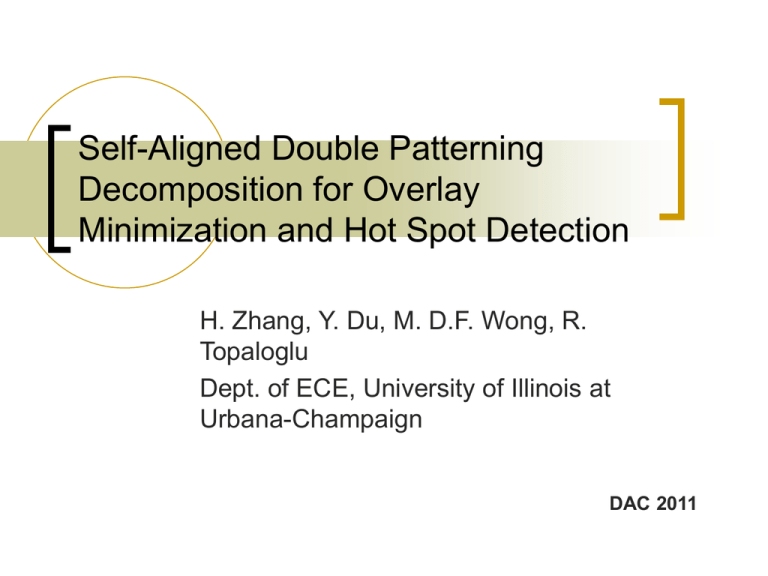

Self-Aligned Double Patterning

Decomposition for Overlay

Minimization and Hot Spot Detection

H. Zhang, Y. Du, M. D.F. Wong, R.

Topaloglu

Dept. of ECE, University of Illinois at

Urbana-Champaign

DAC 2011

Outline

Introduction

Overview of 2D SADP Process

Layout Decomposition Problem Formulation

Problem Reduction

Experimental Results

Conclusions

Introduction

Double patterning lithography (DPL) is the enabling

technology for printing in sub-32nm nodes

DPL technologies can be classified into two major

types:

Double-exposure double-patterning (DEDP)

Single-exposure double-patterning (SEDP)

Self-aligned double patterning (SADP)

Introduction

In SADP process, given a target layout, before the

manufacturing, core mask and trim mask must be

generated from the intended target layout.

Unlike the DEDP, the core mask and trim mask are

not always directly from the original layout.

The problem of generating the core and trim mask

from a 2D designed layout is called SADP

decomposition.

Introduction

Overview of 2D SADP Process

Layout Decomposition

Problem Formulation

Feature Generation and ILP formulation

Layout Decomposition

Problem Formulation

Feature and non-feature region constraint:

Feature is true if and only if this location has trim

mask and no side-wall.

Non-feature region:

Layout Decomposition

Problem Formulation

Core and trim mask geometry constraints:

Sidewall adjacency rule:

Si is 1 if and only if Ci is 0, among the core variables{Cj,

Cj+1,…,Cj+m} within the sidewall width distance, there is at

least one variable equal to 1.

Layout Decomposition

Problem Formulation

Minimum corner-corner rule:

If Ci is 1, Ci+1 is 0 and Ci+2 is 0, then all variables {Ck,

Ck+1, …, Ck+q} within the minimum corner-corner distance

should be 0.

Layout Decomposition

Problem Formulation

Minimum space rule:

If Ci is 1 and Ci+1 is 0, then all variables {Ci+2, Ci+3, …,

Ci+p} within the minimum space distance should be 0.

Layout Decomposition

Problem Formulation

Minimum width rule:

If Ci is 0 and Ci+1 is 1, then all variables {Ci+2, Ci+3, …,

Ci+n} within the minimum width distance should be 1.

Layout Decomposition

Problem Formulation

Objective for Overlay Minimization

The most critical target for the layout decomposition is to

minimize the total overlay, in other words, to maximize the

non-overlay boundaries’ length.

Non-overlay boundary should be guarded by sidewalls,

and the trim mask will overlap with the sidewalls for at

least length W0.

The summation of all the trim variables within distance W0

of any feature to be B.

Layout Decomposition

Problem Formulation

Decomposability Check and Hotspot Detection

By finding the minimum conflicting constraint set, we can

perform hot spot detection.

Inserting extra binary slack variables onto each constraint.

Minimize the summation of the slack variable will be equal

to finding the minimum number of conflicting constraints.

Problem Reduction

Feature Region Variable Reduction

In one single feature, the trim variable will

always be 1, and the sidewall variable will be 0.

Combine core variables in one continuous

feature.

Problem Reduction

Core and Sidewall Variable Reduction

Problem Reduction

Core and Sidewall Variable Reduction

Only need to assign variables on the regions which are

within distance 2Ws+Wc,min.

Problem Reduction

Trim Variable Reduction

Experimental Results

Experimental Results

Experimental Results

Conclusions

This paper has finished the SADP decomposition

process with overlay minimization and hot spot

detection.

For a decomposable layout, this algorithm

guarantees to find a decomposable solution that

minimizes overlay.