NETWORKING WITH DH+

advertisement

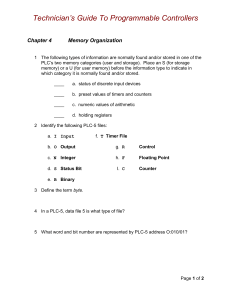

Rockwell Automation Hands-On Seminar Series 1 NETWORKING WITH DH+ 2 2 DH+ Protocol Overview • Peer-to-Peer Communication – Utilizes Tolken Passing • 64 nodes maximum • Remote Programming of SLC 500’S, PLC-2, PLC-3, and PLC-5 • Direct Connections to 5/04,PLC-5, Panelview, and Industrial Terminals • 57.6, 115.2, OR 230Kbaud data rate • Pub # 1770-6.5.16 DH/DH-485/DH+ Ref Manual • Robust Industrial Network 3 3 5/04 and DH+ • Channel 1: 3 Pin Connector SLC 5/04 CPU RUN – Actual DH+ Communication – Beldon #9463 Cable FLT FORCE DH+ BATT RS232 RUN REM PROG • Programming Terminal – Programming and Monitoring • Channel 0: RS-232 Port – – – – DF1 Full and Half Duplex Master and Slave ASCII DH-485 Channel 1 Prog Term Channel 0 4 4 Network Topologies Daisy-Chain – Each device has two sections of cable tied together – Each end has termination (resistor/capacitor) Examples DH+ DH-485 Remote I/O SLC Beldon #9463 cable SLC SLC SLC 5 5 Network Topologies Trunk-Line / Drop-Line – Trunk line very long - run through plant – Drop lines very short – Drops connected to trunk with Y-adapters Examples Data Highway (DH) Devicenet DH+ can be Trunk Line Drop Line SLC Drop Line SLC Drop Line SLC Drop Line SLC 6 6 DH+ Communications RSLogix 500 Software AI 500 Software 6200/AI Software DH+ 57.6Kbaud: 10,000 feet 115.2Kbaud: 5,000 feet 230.4Kbaud: 2,500 feet Other Processors SLC-5/04 PLC-5 PLC-2, PLC-3 PLC-5/250 7 7 DH+ to DH-485 Interface Interface through a 1785-KA5 – Translate DH-485 <-> DH+ – Allows PLC5s and SLCs to communicate SLC 5/04 RSLogix 500 Software PLC-5 PLC-5 DH+ DH+ DH-485 Network #2 DH-485 Network #1 Link Coupler Link Coupler Link Coupler Link Coupler SLC 5/01 SLC 5/02 SLC 5/03 SLC 5/03 8 8 Ethernet Communications Ethernet Ethernet PI Ethernet Gateway DH+ DH+ DH+ PLC-5 PLC-5 with Built-in Ethernet SLC-5/04 9 9