Driving Quality with Visual Management

advertisement

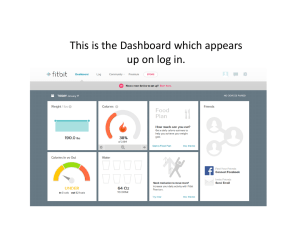

Engaging the C-suite to Advance Pharmacy Practice Providing quality patient care through progressive pharmacy practice Driving Quality with Visual Management Samuel Calabrese, R.Ph., M.B.A., FASHP Associate Chief Pharmacy Officer Cleveland Clinic Cleveland, OH Objectives • Identify various operational and clinical metrics to provide consistency • Describe ways to interpret data within dashboard • Identify methods for incorporating visual management into daily tasks Visual Management The placement in plain view of all tools, parts, production activities, and indicators of production system performance, so the status of the system can be understood at a glance by everyone involved Make your workplace into a showcase that can be understood by everyone at a glance. – Taiichi Ohno Keeping it all Straight • Visual Management – – – – – Prioritize work Identify performance metrics Identify if on/off target Communication of standards Provide real-time feedback Cleveland Clinic Tools • Monthly Review • Daily Review • Business intelligence • Continuous – Business Review Deck improvement – Quality Dashboard activities • Readmissions • Huddles • Core Measures • HCAHPS • Knowledge portal Business Review Deck • User defined Key Performance Metrics – Benchmark – Quality – Financials • Key Volume Indicators – # of doses – Just data: not necessarily benchmarked • Top Projects • Goals – Have discussion Standards should not be forced down from above but rather set by the production workers themselves. – Taiichi Ohno Business Review Deck • Development – Two ½ day sessions • Maintenance – Refreshed monthly • Review – Monthly review using executive summary • Opportunity to discuss issues with the team Pharmacy Business Review Deck Quality / Risk Management Key Volume Indicators Key Volumes Quality Dashboard Enterprise focus – with ability to drill down – Core Measures • SCIP – HCAHPS – Readmissions – Financials MedBoard® • Prioritizing work – Stats visible – Identifies items to be delivered – Identifies items that have been waiting – Identifies where product is within the system – Identifies final delivery location – Communication tool for nursing MedBoard Reporting • Retrospective – Turn-around times – Identifies areas to focus on • Real Time – Where is the dose right now? – Where was it delivered to? May-June MedBoard Data 140 120 Delivery Time On Cart Time RPh Check to Cart Time Rph Check Time Prep Time Verification Time n= 6,496 n= 6,117 n=4,797 100 Median Time (in minutes) Documented to Admin Time 49 n=1,078 50 n=851 n=1,156 n=1,159 80 n=4,946 56 60 13 2 13 28.5 42.5 35 35 35 20 0 7 3 5 6 4 5 9 4 4 7 4 4 12 11 3 2 17 17 6 3 4 6 4 4 35 57 61 n=12,004 3 40 50 n=12,584 6 1 n=3,688 n=3,856 20 5 3 3 11 6 1 8 6 1 9 13.5 8 7 5 3 3 6 6 7 7 6 1 8 1 5 4 27 2 4 Knowledge Portal • Proactively manage automated dispensing cabinets – Inventory – Controlled substances diversion Knowledge Portal Home Screen Knowledge Portal – Watch List Pitfalls to reacting to colors • Comparison group is inappropriate • Patient acuity may be different • Data could be corrupt – Are all systems functioning as usual – Did something change (Upgrades to system?) Dashboards give you a place to start an investigation rather than an endpoint Team Based Visual Management • Team accountability board – Posted where work is actually done – Content based on most important visual information – Updated daily – Agenda for team huddles – Allows for real times fixes Pharm Culture of Improvement Nursing Pharm Culture of Improvement Pharm Culture of Improvement Taussig Phlebotomy Leaders role in Visual Management • Ensuring your team understands the importance – Not useful if not updated – Accountability • Using it – What is your process to review – Have team provide solutions when not hitting target Key Takeaways • Visual management can assist in managing overall business • Visual Management tools can assist in identifying areas needing improvement • Visual management can assist in engaging employees in continuous improvement Reference • Narusawa, Toshiko, and John Shook. Kaizen Express, Fundamentals for Your Lean Journey. Cambridge, MA: Lean Enterprise Institute, Inc., 2009. QUESTIONS