Lecture 33: Otto Cycle

advertisement

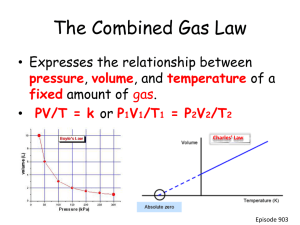

EGR 334 Thermodynamics Chapter 9: Sections 1-2 Lecture 33: Gas Power Systems: The Otto Cycle Quiz Today? Today’s main concepts: • Understand common terminology of gas power cycles. • Be able to explain the processes of the Otto Cycle • Be able to perform a 1st Law analysis of the Otto Cycle and determine its thermal efficiency. • Be able to discuss limitations of the Otto cycle compared to real spark ignition power systems. • Be able to state the assumptions of standard air analysis. Reading Assignment: Read Chapter 9, Sections 3-4 Homework Assignment: Problems from Chap 9: 1, 4, 11, 14 Sec 9.1 : Introducing Engine Terminology Two types of internal combustion engine • Spark Ignition (lower power & lighter) • Compression Ignition (spontaneous combustion) Terminology Stroke : The distance the piston moves in one direction Top Dead Center : The piston has minimum volume at the top of the stroke. Bottom Dead Center : The piston has maximum volume at the bottom of the stroke. Clearance Volume : Min vol Displacement Volume : Max vol. – Min vol. Compression Ratio: Max vol. / min vol. 3 Sec 9.1 : Introducing Engine Terminology Four Stroke Cycle : Two revolutions : Combusts mix of hydrocarbons + O2 1.Intake stroke : fill cylinder •Spark cycle : fill with fuel and air mixture •Compression cycle : fill with air 2.Compression stroke : p , T , V , Win •Spark cycle : spark near end of stroke •Compression cycle : inject fuel 3. Power stroke : gas expands 4. Exhaust stroke : spent gas is exhausted U--Tube video of 4 stroke: http://www.youtube.com/ watch?v=2Yx32F1cncg 4 Sec 9.1 : Introducing Engine Terminology Two Stroke Cycle : Two revolutions 1. Power/Exhaust: •The piston is forced down •@ exhaust port, spent gas leaves •Piston continues down and compresses air/fuel in crank case •Compressed charge enters cylinder 2.Intake/Compression •Piston moves up compressing charge •Draws vacuum in crank case. Two Stroke Animation: http://library.thinkquest.org/C00 6011/english/sites/2_taktmotor.p hp3?v=2 5 Sec 9.1 : Introducing Engine Terminology 6 Mean Effective Pressure (mep) net work from one cycle mep displacement volume Air –standard Analysis (A simplification used to allow for thermodynamic analysis) Assumptions: -- Fixed amount of air modeled as closed system -- Air is treated as Ideal Gas -- Constant cp (cold air-standard) -- Combustion is modeled as a heat transfer to system, Exhaust as heat flow out of system -- All processes internally reversible Ideal Relations: Chap Gas 3: Model Quality 7 Polytropic Process Ideal Gas Model Review State Equation: pv RT pV mRT pV nRT Energy Relationships: H m c p dT mc p T U m cv dT mcv T where kR cp k 1 cp cv R cv R k 1 or look up values for k, cv, and cp on Table A-20 Entropy Relationships: s(T2 , p2 ) s(T1 , p1 ) s o (T2 ) s o (T1 ) R ln where so values are found on Table A-22 p2 p1 s(T2 , p2 ) s(T1 , p1 ) c p ln s(T2 , v2 ) s(T1 , v1 ) cv ln Special case: isentropic process where s1 = s2 then k 1 T2 p2 T2 v1 p2 v1 T1 v2 T p1 v2 1 p1 ( assuming constant specific heats) k T2 p R ln 2 T1 p1 ( k 1) / k v2 vr 2 v1 vr1 T2 v R ln 2 T1 v1 p2 pr 2 p1 pr1 ( vr and pr for use with Table A-22) Sec 9.2 : Air-Standard Otto Cycle 8 Assumption: At top dead center, heat addition occurs instantaneously Otto Cycle: comprised of 4 internally reversible processes Process 1 – 2 : Isentropic compression of air (compression stroke). Process 2 – 3 : Constant volume heat transfer to the air from an external source while piston is at top dead center (ignition) Process 3 – 4 : Isentropic expansion (power stroke) Process 4 – 1 : Completes cycle by a constant volume process in which heat is rejected from the air while piston is at bottom dead center ignition power ignition compression compression exhaust power exhaust Sec 9.2 : Air-Standard Otto Cycle 9 Otto Cycle analysis Closed system energy balance : U Q W Processes 1–2: ∆s = 0 and Q = 0 W12 m u2 u1 Process 3–4: ∆s = 0 and Q = 0 W34 m u4 u3 Processes 2–3 : ∆V = 0 and W = 0 Processes 4-1 : ∆V = 0 and W = 0 Wcycle W12 W34 m u2 u1 u4 u3 Q23 m u3 u2 Q41 m u1 u4 Qin Q23 m u3 u2 Qout Q41 m u4 u1 Sec 9.2 : Air-Standard Otto Cycle 10 Otto Cycle Thermal Efficiency: Qin Qout Qin Qin u3 u2 u4 u1 u3 u2 Wcycle u4 u1 1 u3 u2 Thermal Efficiency can also be related to the compression ratio: clearance displacement volume clearance volume r clearance volume displacement V1 V4 r V2 V3 1 1 r k 1 As the compression ration, r, , the efficiency, η, 11 Example (9.11): An air-standard Otto cycle has a compression ratio of 7.5. At the beginning of compression, p1 = 85 kPa and T1 = 32°C. The mass of air is 2 g, and the maximum temperature in the cycle is 960 K. Determine (a) (b) (c) (d) The heat rejection, in kJ. The net work, in kJ. The thermal efficiency. The mean effective pressure, in kPa. State 1 2 T (K) 305 p (kPa) 85 3 4 960 u (kJ/kg) v T3= 960 K m 2 g 0.002kg p1=85 kPa T1=305 K 12 Example (9.11): (a) (b) (c) (d) The heat rejection, in kJ. The net work, in kJ. The thermal efficiency. The mean effective pressure, in kPa. State 1: Using Ideal Gas Law: v1 State 1 T (K) 305 p (kPa) 85 2 3 960 u (kJ/kg) v pv RT and Table A-22: RT1 (0.287 kJ / kg K )(305 K ) kPa kN m 3 1.0298 m / kg 2 p1 (85kPa ) kN / m kJ u1 217.67kJ / kg State 2: Using compression ratio, ideal gas law, and Table A-22: v1 r v2 v1 1.0298 v2 0.1373m3 / kg r 7.5 4 13 Example (9.11): (a) (b) (c) (d) The heat rejection, in kJ. The net work, in kJ. The thermal efficiency. The mean effective pressure, in kPa. State 1 T (K) 305 p (kPa) 85 u (kJ/kg) 217.67 v 1.0298 2 3 960 0.1373 State 3: using v3 = v2, ideal gas law, and Table A22: v3 0.1373m3 / kg p3 RT3 (0.287 kJ / kg K )(960 K ) kPa kN m 2006.7 kPa 3 2 v3 (0.1373m / kg ) kN / m kJ u3 725.02kJ / kg State 4: Using v4=v1: v4 v1 1.0298m3 / kg 4 14 Example (9.11): (a) (b) (c) (d) (e) The heat rejection, in kJ. The net work, in kJ. The thermal efficiency. The mean effective pressure , in kPa. State 1 T (K) 305 960 p (kPa) 85 2006.7 u (kJ/kg) 217.67 725.02 v 1.0298 T v also knowing for isentropic processes 2 1 T1 v2 2 k 1 0.1373 3 0.1373 p2 v1 p1 v2 4 1.0298 k then for isentropic process 1-2 using k = 1.361 and Table A-22: T2 T1 r k 1 305K 7.5 0.361 631K p2 p1 r 85(7.5)1.361 1319kPa k u2 458.55kJ / kg and for isentropic process 3-4: r T4 T3 1 k 1 960 K 1 u4 328.5kJ / kg 7.5 0.361 464 K p4 p3 r 1 k 2006.7( 1 )1.4 129.3kPa 7.5 15 Example (9.11): (a) (b) (c) (d) The heat rejection, in kJ. The net work, in kJ. The thermal efficiency. The mean effective pressure, in kPa. State 1 2 3 4 T (K) 305 631 960 464 p (kPa) 85 1319 2006.7 129.3 u (kJ/kg) 217.67 458.55 725.02 328.5 v 1.0298 0.1373 0.1373 1.0298 Heat added during process 2-3: Q23 U 23 m u3 u2 kJ 0.002kg 725.02 458.55 0.5329kJ kg Heat rejected during process 4-1: Q41 U 41 m u1 u4 kJ 0.002kg 217.67 328.50 0.2217 kJ kg U Q W 16 Example (9.11): (a) (b) (c) (d) The heat rejection, in kJ. The net work, in kJ. The thermal efficiency. The mean effective pressure, in kPa. State 1 2 3 4 T (K) 305 631 960 464 p (kPa) 85 1319 2006.7 129.3 u (kJ/kg) 217.67 458.55 725.02 328.5 v 1.0298 0.1373 0.1373 1.0298 Net Work over the cycle: Wcycle Qin Qout Q23 Q41 (0.5329) (0.2217) 0.3112kJ Cycle Efficiency: Wcycle Qin Compare to 1 0.3112kJ 0.5839 0.5329kJ 1 r k 1 1 1 0.553 0.4 7.5 17 Example (9.11): (a) (b) (c) (d) The heat rejection, in kJ. The net work, in kJ. The thermal efficiency. The mean effective pressure, in kPa. State 1 2 3 4 T (K) 305 631 960 464 p (kPa) 85 1319 2006.7 129.3 u (kJ/kg) 217.67 458.55 725.02 328.5 v 1.0298 0.1373 0.1373 1.0298 Mean Effective Pressure: net work from one cycle Wcycle mep displacement volume V1 V2 where V1 mv1 0.002kg (1.0298m3 / kg ) 0.0020596m3 V2 mv2 0.002kg (0.1373m3 / kg ) 0.0002746m3 0.3112kJ kN m kPa mep 174.34kPa 3 2 (0.0020596 - 0.0002746)m kJ kN / m 18 End of Slides for Lecture 33