HAND DRYERS VS PAPER TOWELS

advertisement

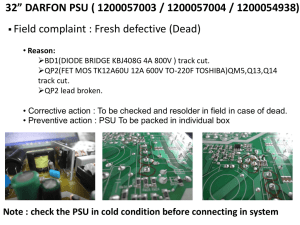

HAND DRYERS OR PAPER TOWELS? By Jacob Billings, Rachel O’Flaherty, Dave Wissman, and Liz Wolcott PSU PAPER TOWEL USE There are a total of 245 bathrooms on campus with 328 paper towel dispensers. 3 types of paper towels are used; all of which are made from 100% recycled fiber and are ecologo certified. Currently PSU orders 2,600 cases of rolled paper towels, 185 cases of single-fold, and 265 cases of multifold a year from Tork (subsidiary of SCA). ASSUMPTIONS ABOUT PRODUCTION/TRANSPORT We assumed that all tissue products require the same amounts of electricity and fuel per pound of product, and that they are all manufactured in the same place made from 100% post-consumer recycled paper. We also assumed the plant consumed electricity produced from the national average mix of sources given by Carbon Counter: 0.42 CO2 per kwh of electricity. Finally we assumed that the towels are shipped in a 4,000 cubic foot truck filled to capacity, that gets 8 miles per gallon, and that the trip is direct from the factory. FACTS REGARDING SCA The nearest SCA factory is in Flagstaff, AZ In 2009 it produced 44,000 metric tons of tissue product. The plant emitted 20,000 metric tons of CO2 from combustion of fuel on site. 57 gigawatt hours of electricity was consumed. This resulted in the plant emitting 43.94 thousand metric tons of CO2 in that year. WHAT THAT MEANS… Is that paper towel production requires an emission of CO2 nearly equal in mass to the towels produced not including emissions from transportation. TRANSPORTATION Diesel combustion emits about 10.1 kg of CO2 per gallon. The total CO2 emission caused by paper towel transportation from Flagstaff to PSU is 2,154.76 kg. PSU 77,218 pounds of paper towel products were purchased in 2009. 35,017 kg of CO2 was emitted just from production of the paper towels purchased. Including transportation, the total CO2 emission from PSU’s paper towel use was 37,171 kg in 2009. HAND DRYERS Xcelerator dryers draw 1500 watts during use. PSU would need to install approximately 350 hand dryers to replace all paper towel dispensers on campus. We assumed that the hand dryers have a ten year life-span and that they are transported in the same way as paper towels. We also assumed that 1 watt of electricity is used for standby power, 750 for 1.5 seconds after use for power down, PSU’s electricity source emits 0.00082495 kg of CO2 per kwh. For the comparison it is assumed that an individual drying with a hand dryer takes 12 seconds and 1 to 3 feet of paper towels are used. MANUFACTURING AND TRANSPORTATION According to third party life-cycle analysis firm Quantis, the manufacture of a single Xcelerator hand dryer requires the emission of about 212 kg of CO2. The dryers are manufactured in East Longmeadow, MA making the long-term average annual CO2 emission from transporting hand dryers to PSU 381.401 kg. PSU The long-term average annual CO2 emission from manufacturing hand dryers for PSU campus would be 7,420 kg. The long-term average annual CO2 emission from transportation would be 381.401 kg. ELECTRICITY & CO2 Consumption from hand dryers Replacing all paper towel dispensers with hand dryers would consume between 37,935 and 71,087 kwh per year in use and in power down electricity per year. Standby time would be between 8,617 and 8,684 hours per dryer per year. Emissions from hand dryers Hand dryer use would emit between 19,195 and 35,970 kg of CO2 per year. Annual CO2 emissions from standby power consumption would be between 1,526 and 1,538 kg. Total CO2 emissions from electricity consumed would be between 20,733 and 37,496 kg. RESULTS PAPER TOWELS The total CO2 emissions from PSU’s paper towel purchases is 37,171 kg. HAND DRYERS The total long term average annual CO2 emissions from hand dryers would be between 28,258 and 45,021 kg. THE BREAKING POINT PRICE COSTS In 2009 PSU spent $74,119.10 on paper towels. The lowest perceivable cost of installation for hand dryers would be $117,950. The lowest estimated cost of electricity used by hand dryers is $3,099.27, the highest $5,807.81 SAVINGS By installing hand dryers PSU would save $68,311.29 if the hand dryers are used at our highest estimated projections, $71,019.83 if they are used at our lowest estimates. The initial cost of installation would be recovered in 1.66 to 1.73 years. RESULTS & PROPOSAL Our research shows that if the hand dryers are used at our highest estimates PSU will increase its CO2 emissions by 7,849.90 kg a year. However if the hand dryers are used at our lowest estimates then PSU will reduce its CO2 emissions by 8,913.2 kg. The prior graph shows that if individuals use 1.5 ft of paper towels or more hand dryers will be the better choice for reduction of carbon emissions. Considering the size of a 1.5 ft piece of paper towel it is safe to assume that most individuals use at least that amount when drying their hands. As a result we conclude that changing from paper towels to electric hand dryers will be a good choice in reducing carbon emissions on campus.