Thin Hot Mix Asphalt Overlays

advertisement

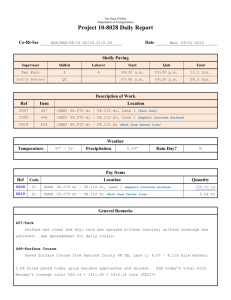

Thin Hot Mix Asphalt Overlays PennDOT Research Findings Pennsylvania Asphalt Pavement Association 53rd Annual Asphalt Paving Conference Hershey, PA December 12, 2012 1 Thin Overlay Development Back GroundNEPPP: Smooth Seal in Ohio, THMAO in NY PAPA Technical Sub Committee • Created draft specification • 6.3mm PG 76-22, Polymer Modified, 75 Gyration mix Research Project approved 2 Special Provision 6.3 mm – 100% passing 3/8 in. Dense –graded ( 6 sieve sizes) - SRL PG 76-22 polymer modified N design = 75 gyrations Design voids = 4.0% Min. VMA = 16.5 No RAP or RAS Greater than 50 F Optimum Rolling Pattern 3 Use Guidelines Only on structurally sound pavement Same as micro-surfacing For correcting surface distresses only Consider grinding PCC first 4 Tack Coat Specification SS – 1h or CSS – 1h RS – 1h or CRS – 1h 60% min residue Low pen (40-90) asphalt residue 0.05-0.06 gal/sy rate. 5 Mix Design – Hempt Bros. 6 trial blends to get minimum VMA Component materials -baghouse fines ( 1.9%) -Toland Conc sand Type A, SRL-E (39.4%) -Toland ¼ in. SRL-E - 4.0% passing #200 - 43% passing #8 - NuStar PG 76-226 binder (6.7%) Mix Design (cont’d) Volumetrics - N design : 75 gyrations - design voids: 4.0% - VMA: 17.1% - VFA: 77% - TSR: 83% (without antistrip) 7 6.3 mm NMAS Mix Placed at 1 inch thickness Aggregate: Sandstone, Skid Resistance Level (SRL): E Polymer Modified Binder: PG 76-22 Gyration Level: 75 Design Air Void: 4%, Design VMA: 17.1 Design Binder Content: 6.7% NO RAP 8 Construction All night work 1/3 mile of four lanes (612 tons) Including intersection and turn lane 1 in thick overlay on diamond ground PCC CSS-1h tack coat 0.06 gal/sy tack application rate 9 Performance Evaluation - HWTD Good Performance Thin Asphalt Overlay Project Hamburg Wheel Tracking Tests - 8/23/2012 6 Rut Depth, mm 5 Right Track 4 Left Track 3 2 Temperature = 50ºC 1 0 0 2 4 6 8 10 12 14 Number of Wheel Passes (X1000) 10 16 18 20 Performance Evaluation – Overlay Tester Test Temperature: 25ºC # of load cycles: 1200 Or until load reduced to 93% of original Repeated loading (triangular form) under constant deformation Deformation magnitude per load cycle: 0.025 inches (0.6 mm) Duration of each load cycle: 10 seconds 11 Performance Evaluation – Overlay Tester Good Performance Cycles to failure > 500 High variability in data 12 Tack Coat Evaluation Notice Displacement of the Asphalt Layer 13 Tack Coat Evaluation Shear Strength = 44.5 psi (307 KPa) - Good Performance THMAO Project Tack Coat Evaluation - Core # 5 Interface Shear Stress, KPa 350 Deformation Rate: 1 mm/min Test Temperature: 25.5 C 300 250 200 150 100 50 0 0 1 2 3 Interface Shear Deformation, mm 14 4 5 Emulsion Tack Coat Application 15 Smooth Mat Right Behind The Paver 16 Mat Temperature Mat Temperature, °F THMAO Project - N. Cameron Street, WB, Passing Lane Mat Temperature (Spot Measurment) - 7/23/12 - 7/24/12 330 310 290 270 250 230 210 190 170 150 130 Location 3 Location 2 Location 1 Pavecool Prediction (Wind Speed = 5 mph) 0 5 10 15 20 Elapsed Time from Placement, minutes Data is courtesy of Mr. Garry Hoffman 17 25 30 Core Densities 18 Friction Improvement Data: Courtesy of PennDOT BOMO 19 Ride Quality (Smoothness) Improvement Data: Courtesy of PennDOT BOMO 20 Summary/Findings Good Mix Lab Performance • Permanent Deformation (SST) • Rutting and Moisture Resistance (HWTD) • Crack Resistance (Overly Test) Good Tack Shear Resistance Improved Ride and Friction In-Place Average Density: 92.2% (based on 9 cores) • (Cores from Test Strip Only) • Could be better if compaction finished at higher temperature? Mat Temperature After Placement: 280-315ºF Rapid Mat Cooling No Apparent Segregation Coring Not A Problem 21 Conclusions Thin Overlays for Pavement Preservation Improved Ride Quality Improved Friction Maintained Road Geometrics Reduced Noise Reduce Life Cycle Costs Provide Long Lasting Service Place before extensive rehab required according to use guidelines Expected performance 10 years on asphalt 6 or more on PCC 22 Thin HMA Overlays Thin HMA overlays are an added solution to pavement preservation. They are economical, long-lasting, and effective in treating a wide variety of surface distresses to restore ride quality, skid resistance, and overall performance. 23