ATEX 137 - Power Electronics

advertisement

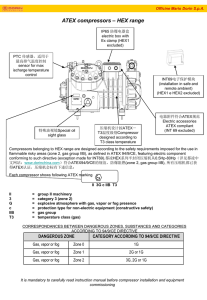

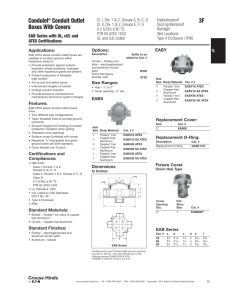

VSD AND SS DRIVING ATEX MOTORS February 2014 1 Introduction to ATEX 2 ATEX motor designation 3 VSD Sample Solutions 4 SS descriptions Introduction to ATEX EU territory define the use of electrical equipment in potentially explosive atmospheres, within the directives 1992/92/EC and 94/9/EC. 1992/92/EC (ATEX 137) covers the minimum requirements for improving the health and safety protection of workers operating in potentially explosive atmospheres. 94/9/EC (ATEX 95) is intend to allow free trading of equipment and systems for use in a hazardous area without the need for separate testing and documentation. ATEX 95 ATEX 137 Product Directive 94/9/EC Requirements and certifificates for manufacturers Workers Protection DIrective 1999/92/EC Classifies zones and states the corresponding product category *EHSRs Zones Product Requirements * Essential health and safety requirements Category 1 Zone 0/20 Category 2 Zone 1/21 Category 3 Zone 2/22 Risk analysis Introduction to ATEX CENELEC / IEC Standards provide a criteria which determine the classification of the equipment into groups and categories according to EN / IEC 60079-0: Depending on the intended use, explosion proof electrical operating equipment is divided into two major groups: Group I: Equipment for coal mines (only special designed motors for mines can be used) Group II: Electrical equipment for use other than mines (surface industry) GROUP I ( MINES) DESCRIPTION Equipment designed to operate on environments where the explosive atmosphere is present frequently Equipment that must be powered off if there is any risk of explosion. Explosive atmosphere is present frequently. CAT M1 M2 GROUP II ( SURFACE INDUSTRY) CAT 1 2 3 GRUPO IIA DESCRIPTION Equipment with high degree of protection. Explosive atmosphere is present continuously or for long periods of time. Equipment with high degree of protection. Explosive atmosphere may occur occasionally.. Equipment with normal degree of protection. The explosive atmosphere will probably not occur. LABEL ZONE 1G (gas) 1D (dust) 0 (gas) 20 (dust) 2G (gas) 2D (dust) 1 (gas) 21 (dust) 3G (gas) 3D (dust) 2 (gas) 22 (dust) SUB-GROUP CLASSIFICATION FOR GASES OF EXPLOSURE ATMOSPHERES ( FLAME PROOF MOTORS) DESCRIPTION Acetone, ammonia, benzene, butane, butanol, alcohol butylic, ethane, ethanol, acetate of ethyl, gasoline, hepthanes, hexanes, natural gas, methanol, naphtha, propane, propanol, toluene, esthirene, solvents in general IIB Acetaldeide, cyclopropane, diethylic ether, ethene, monoxide of carbon IIC Acetylene, butadiene, oxide of ethene, hydrogen, oxide ofpropylene, gases containing over 30% of hydrogen ATEX MOTOR DESIGNATION AND AREAS MOTOR DESIGNATION TYPE DESCRIPTION tD/DIP Protection by dust ignition prove enclosure according to IEC 61241-1 nA Not sparking. Increased safety in terminal box. d Explosion Proof (Rugged frame) de Explosion Proof with Increased Safety Terminal Box e Increased Safety. Increased safety in terminal box. p Pressurized. (Special construction) CLASSES OF TEMPERATURE The minimum temperature that causes an explosion of a gas, vapour of explosive mixture is called ignition temperature. To avoid any risk of explosion, the motor surface temperature must always stay below the ignition temperature of the explosive mixture. Class of Temperature (ºC) NEC Maximum motor surface temperature (C) T1 450 T2 T2 T2A 12B T2C T2D 300 280 260 230 215 T3 T3 T3A T3B T3C 200 180 165 160 T4 135 120 T5 T4 T4A T5 T6 T6 EN / IEC 60079-0 T1 100 85 VSD SAMPLE SOLUTION Solution for “Ex nA” y “Ex tD/DIP” (T3, T4, T5, T6 < 200ºC) y “Ex d, de y p” en Zone 2 o ATEX (PT100 or PTC) temperature relay that can be either connected to the drive’s STO or the upstream disconnector. o Appropiate motor sizing(motor derating) o Switching frequency >3kHz o Declaration of conformity. Power Electronics assumes the responsibility. Solutions for Ex d y Ex p motors (Zone 1) : o The intrinsic construction of the motors reduce all the risk except the overheating of the motor housing o That risk can be eliminated by installing: o ATEX (PT100 o PTC) relay connected to the drive’s input safe stop STO (SD700 only). o ATEX (PT100 o PTC) relay connected to the upstream disconnector. o Appropiate motor sizing(motor derating) o Switching frequency >3kHz The installation of an “Ex e” motor in Zone 1 or 2 is not feasible. SD700 offers unique features that reduces associated hazard effects in ATEX Zones: o It integrates built-in as standard a dV/dt filter and a CLAMP system that reduce dV/dt rise time to (500V/µs -800V/µs) o Reduce Peak Voltages at the Motor Winding o Reduce CMC and bearing currents that reduce the risk of winding sparks. o Works at a switching frequency over 4kHz that reduce motor overheating o Built-in and adjustable motor thermal model. DERATING CURVE FOR ABB MOTORS nA motors derating PWM converters fs>3kHz tD/DIP motors derating PWM converters fs>3kHz SS DESCRIPTION Power Electronics’ soft starters V2, V5 y VS65 do not produce any abnormal electric performance that the Direct On Line Start shall cause under normal conditions. Except if the starting sequence takes too long or the number of starts are above the one that the motor manufacturer determines. Solution for Ex nA y Ex tD/DIP motors ( Zone 2): o Declaration of conformity including a limitation considering number of starts per hour and maximum starting time. Power Electronics assumes the responsibility. Solution for Ex d y Ex p (Zone 1) : o The intrinsic construction of the motors reduce all the risk except the overheating of the motor housing o That risk can be eliminated by installing: o ATEX (PT100 o PTC) relay activating the line contactor (VS65) o ATEX (PT100 o PTC) relay connected to the upstream disconnector. The installation of an “Ex e” motor in Zone 1 or 2 is not feasible. POWER ELECTRONICS appreciate your attention More info: www.power-electronics.com