Lecture 16

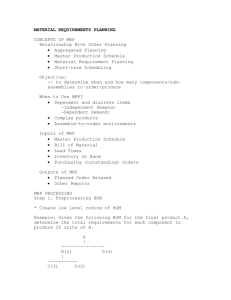

advertisement

ISEN 315 Spring 2011 Dr. Gary Gaukler Hierarchy of Planning • Forecast of aggregate demand over time horizon • Aggregate Production Plan: determine aggregate production and workforce levels over time horizon • Master Production Schedule: Disaggregate the aggregate plan and determine per-item production levels • Materials Requirements Planning: Detailed schedule for production/replenishment activities Push and Pull Production Control The inventory control methods covered so far are useful for “independent demand” situations: Now, introduce methods to deal with “dependent demand”: Push and Pull Production Control “Push” system: Determines when and how much to produce based on forecasts of future demands “Pull” system: Initiates production of an item only when the item is requested Dependent Demand Effective use of dependent demand inventory models requires the following 1. 2. 3. 4. 5. Master production schedule Bill of material (BOM) Inventory availability Purchase orders outstanding Lead times Master Production Schedule Specifies what is to be made and when MPS is established in terms of specific products The MPS is a statement of what is to be produced, not a forecast of demand MPS Example Example: How to determine MPS? Bill of Materials List of components, ingredients, and materials needed to make product Provides product structure Items above given level are called parents Items below given level are called children BOM Example Level Product structure for “Awesome” (A) 0 A B(2) Std. 12” Speaker kit 1 E(2) 2 3 D(2) C(3) Std. 12” Speaker kit w/ amp-booster E(2) Packing box and installation kit of wire, bolts, and screws F(2) G(1) Std. 12” Speaker booster assembly D(2) Amp-booster 12” Speaker 12” Speaker BOM Example Level Product structure for “Awesome” (A) 0 A Part B: 2 x number of As = Part C: 12”3 Speaker x number B(2) Std. kit of As = 1 Part D: Part E: 3 2 x number of Bs Part F: 2 x number of Cs = Part G: 1 x number of Fs = 12” Speaker F(2) Std. 12” Speaker booster assembly 2 x number of Bs Packing box and + installation 2 x number Cs kit ofof wire, bolts, and screws D(2) Std. 12” Speaker kit w/ amp-booster + 2 x number of Fs = E(2) E(2) 2 C(3) = G(1) D(2) Amp-booster 12” Speaker Lead Times The time required to purchase, produce, or assemble an item For purchased items – the time between the recognition of a need and the availability of the item for production For production – the sum of the order, wait, move, setup, store, and run times Time-phased Product Structure Must have D and E completed here so production can begin on B Start production of D 1 week D 2 weeks to produce B 2 weeks E A 2 weeks 1 week E 1 week 2 weeks G C 3 weeks F 1 week D | | | 1 2 3 | | 4 in weeks 5 Time | | | 6 7 8 Determining Gross Requirements Starts with a production schedule for the end item – 50 units of Item A in week 8 Using the lead time for the item, determine the week in which the order should be released – a 1 week lead time means the order for 50 units should be released in week 7 This step is often called “lead time offset” or “time phasing” Determining Gross Requirements From the BOM, every Item A requires 2 Item Bs – 100 Item Bs are required in week 7 to satisfy the order release for Item A The lead time for the Item B is 2 weeks – release an order for 100 units of Item B in week 5 The timing and quantity for component requirements are determined by the order release of the parent(s) Determining Gross Requirements The process continues through the entire BOM one level at a time – often called “explosion” By processing the BOM by level, items with multiple parents are only processed once, saving time and resources and reducing confusion Gross Requirements Plan 1 A. B. C. E. F. D. G. 2 3 Week 4 5 6 Required date Order release date 8 Lead Time 50 50 Required date Order release date 1 week 100 100 Required date Order release date 2 weeks 150 150 Required date Order release date 200 200 Required date Order release date 1 week 300 300 1 week 300 300 Required date Order release date Required date Order release date 7 3 weeks 600 600 200 200 1 week 300 300 1 week Table 14.3 The Logic of Net Requirements gross allocations requirements + total requirements – on scheduled hand + receipts available inventory net = requirements Net Requirements Plan Net Requirements Plan Net Requirements Plan Starts with a production schedule for the end item – 50 units of Item A in week 8 Because there are 10 Item As on hand, only 40 are actually required – (net requirement) = (gross requirement - on- hand inventory) The planned order receipt for Item A in week 8 is 40 units – 40 = 50 - 10 Net Requirements Plan Following the lead time offset procedure, the planned order release for Item A is now 40 units in week 7 The gross requirement for Item B is now 80 units in week 7 There are 15 units of Item B on hand, so the net requirement is 65 units in week 7 A planned order receipt of 65 units in week 7 generates a planned order release of 65 units in week 5 Net Requirements Plan A planned order receipt of 65 units in week 7 generates a planned order release of 65 units in week 5 The on-hand inventory record for Item B is updated to reflect the use of the 15 items in inventory and shows no on-hand inventory in week 8 Lot Sizing For MRP Systems Given: Net requirements Determine: When and how much to produce / order Simplest Lot Sizing: Lot-for-Lot Gross requirements 1 2 3 4 5 6 7 8 9 10 35 30 40 0 10 40 30 0 30 55 35 0 0 0 0 0 0 0 0 0 0 30 40 0 10 40 30 0 30 55 30 40 10 40 30 30 55 40 30 Scheduled receipts Projected on hand Net requirements 35 Planned order receipts Planned order releases 30 40 10 30 55 Lot Sizing For MRP Systems Assumptions: • Consider only one item • Demand known and deterministic • Finite horizon • No shortages • No capacity constraints Lot Sizing For MRP Systems Problem formulation: Lot Sizing For MRP Systems Does this look like an EOQ problem? EOQ Lot Size Example Gross requirements 1 2 3 4 5 6 7 8 9 10 35 30 40 0 10 40 30 0 30 55 35 0 0 0 0 0 0 0 0 0 0 30 0 0 7 0 4 0 0 16 Scheduled receipts Projected on hand Net requirements 35 Planned order receipts Planned order releases 73 73 73 73 73 73 73 73 Holding cost = $1/week; Setup cost = $100; Average weekly gross requirements = 27; EOQ = 73 units How did we obtain EOQ? Lot Sizing: Silver-Meal Heuristic In any given period, produce to cover demand in a future period as long as the average cost per period is reduced by doing so Algorithm: 1. Start in period 1. Calculate C(t): average per-period cost if all units for next t periods produced in period 1. 2. Select lowest t such that C(t)<C(t+1): t* 3. Produce t* in period 1 4. Repeat, starting from period t*+1 Silver-Meal Example Assume net requirements are 18, 30, 42, 5, 20 Setup cost for production is $80 Holding cost $2 per unit per period