Portland-Limestone Blended Cements

advertisement

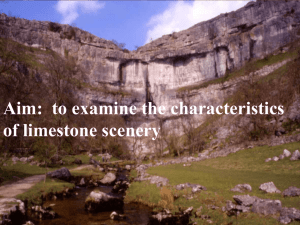

Portland - Limestone Blended Cement Karl Zipf DelDOT - 2014 The following is an edited presentation from the Portland Cement Association This is not an endorsement for the PCA DelDOT does not have any test data to verify their claims. Portland-Limestone Blended Cements Portland-Limestone Cement What is a PLC? Type IL blended cement in ASTM C595/AASHTO M240 5% to 15% limestone by mass Ternary cements Why the proposal? Option to implement proven technology to obtain desired performance and improve sustainability of concrete ENVIRONMENTAL BENEFITS Increases plant capacity Reduces carbon footprint Saves energy Energy to Produce Cement Environmental Benefits - CO2 Portland cement 1.0 Portland-limestone cement kg CO2/kg cement 0.8 0.6 0.4 0.2 0.0 Plant 1 Plant 2 Plant 3 History of Limestone in Cements 1965 Cement with 20% limestone in Germany for specialty applications 1979 French cement standards allows limestone additions. 1983 CSA A5 allows up to 5% limestone in portland cement 1990 15±5% limestone blended cements routinely used in Germany 1992 UK specs allows up to 20% in limestone cement 2000 EN 197-1 allows 5% MAC (typ. limestone) in all 27 common cements, as was commonly practiced in various European cement standards prior to that. 2000 EN 197-1 creates CEM II/A-L (6-20%) and CEM II/B-L (21-35%) 2004 ASTM C 150 allows 5% in Types I-V 2006 CSA A3001 allows 5% in other Types than GU 2007 AASHTO M85 allows 5% in Types I-V 2008 CSA A3001 includes PLC containing 5%-15% limestone European Cement Use 100 90 6.1 3.2 4.0 1.7 3.4 5.0 2.1 1.5 5 5.5 6.5 1.8 1.9 9.5 4.8 5.6 2.1 2.9 5.4 2.2 1.8 5.7 5.1 5.6 14.3 12.5 16.8 14.5 9.6 16.8 Cement Types in Europe (%) CEM V - Composite Cement CEM IV - Pozzolanic CEM III - Blast furnace slag 80 CEM II - Portland-composite CEM II - Portland-limestone 70 60 Others CEM II - Portland-fly ash 15.0 18.9 24.6 CEM II - Portland-pozzolana 24.0 24.5 31.4 CEM II - Portland-slag CEM I - Portland 50 40 5.4 3.7 4.8 6.2 2.9 5.4 5.7 2.1 4.2 7.0 2.7 6.8 6.9 1.2 5.9 30 20 35.4 34.2 33.7 32.1 31.6 7.4 1.4 4.5 27.5 10 0 Cembureau data Why 15%? How Limestone Works Particle packing Improved particle size distribution The same effect with packing can be had be be had with fly ash. How Limestone Works Nucleation Surfaces for precipitation Any small particle will act as nucleation sites. Performance: Strength Performance: RCPT T277/C1202 No change Charge Passed (Coulombs) 3000 28 days 56 days 2000 PC PLC 1000 0 No SCM No SCM W/CM = 0.40 35% Slag 20% Fly No SCM No SCM 35% 20% Fly Ash Slag Ash W/CM = 0.40 W/CM = 0.45 W/CM = 0.45 ASR Resistance Expansion (%) 0.4 PC 0.3 PLC 0.2 0.1 0 AMBT CPT (14 days) (1 Year) ACPT (3 months) Test (age when expansion reported) Field Trials – T277/C1202 AASHTO M240 & ASTM C595 Requirements Type IL—Portland-limestone blended cement Example: Type IL(10) = 10% limestone Type IT—Ternary blended cement with limestone Example 1: Type IT(L10)(P10) = 10% limestone and 10% pozzolan Example 2: Type IT(S15)(L10) = 15% slag and 10% limestone Limestone content 5% to 15% AASHTO M240 & ASTM C595 Requirements Same physical requirement as existing C595/M240 cement types Chemical require changes– sulfate content, LOI Sulfate resistance – no MS or HS in initial ballot Limestone quality specs – %CaCO3, MBI, TOC Not all cement quarries will have limestone that meets the standard. Requirements for Limestone for Use in Type IL – Cannot add agriculture limestone to Portland cement Test Method Limit C114/T105 Min. 70% Methylene blue index See Annex A2 Max. 1.2 g/100g Total organic carbon See Annex A3 Max.0.5% CaCO3 content Additional Information Cement fineness is 480-500. Limestone is more friable than clinker in grinding and particle size is controlled to control set and strength. PCA claims that higher fineness does not affect water demand. Limestone is inert and does not react. Several states have already approved Type IL There is no price benefit in using PLC. PLC can be available in this area Portland Limestone Blended Cement in ASTMThank C595you! and AASHTO M240 Presented to ASTM C01.10 December 2010