Isolation & identification of Novel microorganisms for the Treatment

advertisement

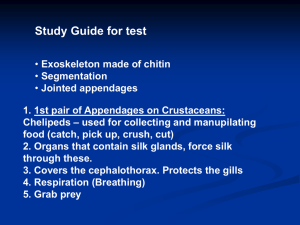

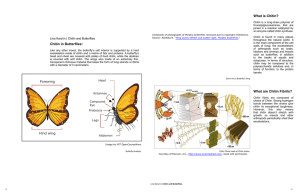

Carla Harkin Dr Wolfram Brück Dr Catherine Lynch Dr Denis McCrudden Development of efficient, economical and environmentally-friendly pre-treatment of crustacean shell wastes to extract chitinous material (Raw material sources: Europe/Asia/Africa). Stabilisation of chitinous material for transfer to project partners (UMB, INS, TUM, FhG). Development of assays for constant quality control. Raw material Prep Optimisation of chemical chitin extraction methods Identification of novel microorganisms Optimisation of microbial chitin extraction methods Up-scaling QC 7. QC Analysis Chemical extraction methods- costly and a hazard to the environment. Biological extraction methods- more cost effective while posing less cause for environmental concern. Microbial chitin extraction methods: Direct use of enzymes (Brück et al, 2011; Jo et al, 2011). Fermentation (Jung et al, 2005; Jung et al, 2007; Rao et al, 2000). Fermentation Initial optimisation, adapting methods from literature. Identification of novel microorganisms for fermentation. Raw material + Inoculum Shaking Incubator QC Harvesting & drying Shaking Incubator (Jung et al., 2005; Jung et al., 2007a,b; Oh et al., 2007) Change of Inoculum Isolation from soil samples Screening for useful properties Small scale fermentation Identification Large scale fermentation Characterisation Demineralisation–acid production. Replicated fermentation method on micro scale. Fig 1: pH indication after addition of Methyl Red Indicator. L-r: negative yellow, negative orange, positive intense red. Deproteinisation–protease production. Casein agar plates. Colorimetric protease assay to quantify activity (Vishwanatha et al, 2009). Fig 2: Produciton of zone of proteolysis in casein agar. Property No. of Organisms Protease producing 57 Acid producing 45 Protease & Acid producing 16 • Identification of isolates; PCR, sequencing- BLAST • Characterization of isolates: biochemical tests, staining etc. • Continue to meet chitinous material production targets. • Continuation of fermentation experiments using raw crustacean waste from Ireland, Indonesia and Tunisia. • With select cultures, the aim is to scale-up fermentations to pilot scale to investigate the reality of industrial large scale fermentations in the breakdown of crustacean waste. • Development of an economic, environmentally friendly, waste reducing facility. • Profit-generating business opportunities for Irish Seafood Industry. Brück, W., M., Slater, J. W., Carney, B. F., 2011. Chitin and chitosan from marine organisms. Chitin, Chitosan, Oligosaccharides and their derivatives. Boca Raton: CRC Press. Vishwanatha, T., Spoorthi, N., Reena, V., Divyashree B.C., Siddalingeshwara K.G., Karthic, J., Sudipta K.M., 2010. Screening of substrates for protease production from Bacillus lichenformis. International Journal of Engineering Science and Technology (2)11, pp. 6550-6554 Jung, W.J., Jo, G. H., Kuk, J. H., Kim, K. Y., Park, R. D., 2005. Extraction of chitin from red crab shell waste by cofermentation with Lactobacillus paracasei subsp. tolerans KCTC3074 and Serratia marcescens FS-3. Applied Microbiology and Biotechnology (71) pp. 234237. Jung, W.J., Jo, G. H., Kuk, J. H., Kim, Y. J., Oh, K. T., Park, R. D., 2007. Production of chitin from red crab shell waste by successive fermentation with Lactobacillus paracasei KCTC-3074 and Serratia marcescens FS-3. Carbohydrate Polymers (68) pp. 746-750. Oh, K. T., Kim, Y. J., Nguyen, V. N., Jung, W.J., Park, R.D. 2007. Demineralization of crab shell waste by Pseudomonas aeruginosa F722. Process Biochemistry. (42) pp. 1069–1074. Jo, G.H., Park, R.D., Jung, W.J., 2011. Enzymatic production of chitin from crustacean shell waste. Chitin, Chitosan, Oligosaccharides and their derivatives. Boca Raton: CRC Press. Rao, M. S., Muñoz, J., Stevens, W. F., 2000. Critical factors in chitin production by fermentation of shrimp biowaste. Applied Microbiology and Biotechnology (54) pp. 808813. Thank you very much for your attention.