Steel Wood Truss - City Tech OpenLab

advertisement

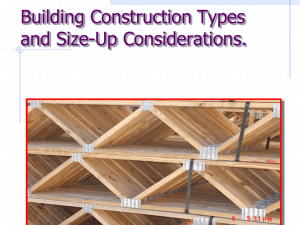

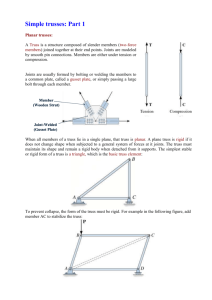

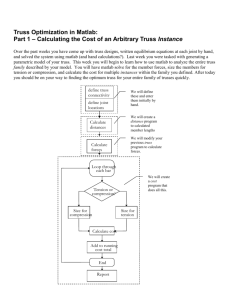

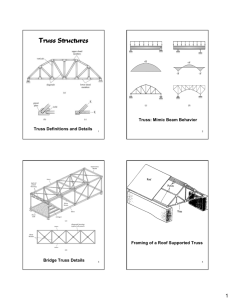

Long Span Truss Construction Jia Rui Lin Guanlin Du Diego Vega Elvio Gimenez Trusses A truss consists of straight members connected at joints (not continuous through a joint), all laying in the same plane and connected to form a triangle or a series of triangles. Truss members are slender and cannot support large lateral loads. Truss Terms Typical Truss Configurations More Typical Truss Configurations More Typical Truss Configurations Bridge Truss (Warren) Above: Willis Avenue Bridge, New York Right: Prefabricated Willis Ave Bridge truss floating under the Brooklyn Bridge. Video at: http://www.nypost.com/p/news/local/willis_ave_bridge_floats_toward_VqxnJtnUw8rdnEWBefKpTI Roof/Floor Truss (Warren) Small Office Building, Far Rockaway, NY (2005) STEEL FRAME • Steel frame usually refers to a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. • A number of different floor slab types can be used in association with a steel frame. The floor slab usually spans one way; it is either simply supported or continuous. Most slab types can be designed to act compositely with the supporting beams if adequate shear connection is provided • Composite floor slabs use metal decking, which spans between secondary steel beams usually spaced at between 2.5 and 3m centres. Metal decking acts both as permanent formwork for the concrete, eliminating the need to provide props, and as tensile reinforcement for the slab. Steel bars are included in the slab to prevent cracking and to provide reinforcement in the event of degradation of the decking in a fire. This was the schematic of the original World Trade Center Floor System http://upload.wikimedia.org/wikipedia/commons/thumb/8/86/Wtc_floor_truss_system.png/800px-Wtc_floor_truss_system.png • Alternative arrangements of primary and secondary beams can be adopted for an optimum deck span of 3m. and a typical system is illustrated. • Longer spans are possible using composite steel floor trusses, but fabrication costs are higher. Use of composite steel floor trusses as primary beams in the structural floor system permits much longer spans than would be possible with conventional universal beams. Maximum span for floor trusses is about 30m and truss depth can be estimated as span/15. Wood Truss • • • • • • • • • Advantages Trusses are built with 2x4 or 2x3 lumber oriented ‘flatwise,’ providing a wide, stable bearing surface that is easier to work on and around. Wide nailing surface provides for easy gluing and ensures more accurate fastening of the sheathing, reducing squeaks and improving floor performance for the life of the structure. Spacing floor trusses at 19.2" or 24" on center maximizes structural efficiency and speed of installation. Typical depths for floor trusses are 12" to 24", but shallower or deeper depths are possible. Open web configuration leaves plenty of room for plumbing, electrical and mechanical runs. Floor trusses are manufactured with high-quality lumber, which minimizes shrinkage, warping or twisting, reducing the potential for call backs to the jobsite. Floor trusses can be designed to bear on the top chord or at intermediate depth, allowing the trusses to be supported on raised beams without requiring hangers, thereby reducing the potential for floor squeaks and call-backs. Stiffness and strength can be designed into floor trusses to create a more solid floor, and special bearing, cantilever and balcony details can easily be built into the design. Long spans and girder truss options reduce the need for intermediate bearing walls, beams, columns and footings –saving time and construction costs. Wood Truss Detail Wood Truss Detail Wood Truss Detail Reinforced Concrete http://www.freepatentsonline.com/20060272267.pdf Waffle System http://www.freepatentsonline.com/20060272267.pdf Concrete Waffle Slab Concrete Waffle Slabs Benefits of waffled slabs: • Services can be integrated into the depth of the slab. • Reduces the number of columns or load bearing walls needed by 10-20%. • Adds up to greater efficiency and energy savings. • Breaks up sound reflections. • Eliminates the need for suspended ceilings. ER Post™ Structural System The ER Post™ Structural System from Spancrete was developed and patented by Ericksen Roed & Associates. http://eraeng.com/ http://www.freepatentsonline.com/7010890.html ER Post™ Structural System http://www.freepatentsonline.com/7010890.html ER Post™ Structural System http://eraeng.com/er-post/er-post-advantages/ ER Post™ Structural System https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&cad=rja&uact=8&ved=0CCgQFjAA&url=http%3A%2F%2Fwww.span crete.com%2Fdownload.php%3Fobj_id%3D211&ei=LCEpU6m8Jue70gHu64GoAw&usg=AFQjCNFmr92zuyrk283B6AcaeBfIPFrn5A&sig2=bn1GK MDpYWOB_vKFK4B4Qg Strength to Weight Higher Strength to Weight ratio • The removal, exchange or rearrangement of material in specific locations within the structure that can allow the member to achieve a higher level of strength whilst maintaining or reducing its original weight. Wood together with steel Red built: engineered wood products Taylor Middle School Cafeteria Benefits of Steel on Wood • Longer span can be achieved. • Slim members in truss design means more clearance in between openings. • Wood can be treated for durability. • Steel can be galvanized for durability. • Material combinations can be achieved to create more appealing/interesting that lead to exposed structures. The Castellated–Cellular Beam Benefits of Castellated Beams • • • • • • • • • • • • 50% deeper, i.e., 50% stronger, with no added steel. Greater strength-to-weight ratio. Strength can be precisely matched to support the load. Spans of 90 feet and greater, depths up to 48 inches. Easier handling due to lighter weight. Longer span beams are fast, easy to install. Lighter framing reduces column, footing sizes. MEPs pass through web openings. Straight, camber and combined weight options. Available galvanized options. Easily fireproofed on jobsite. Can be made entirely from recycled materials. Note • Because of the weight reduction and the rearrangement of material, often times must be braced laterally by purlins, girts, decking or diagonal bracing to prevent them from buckling. Sites • http://www.redbuilt.com/applications/projects.aspx?id=15 • http://www.newmill.com/downloads/rooflines/archives/2012/ebulletin-july2012.html • http://www.treehugger.com/green-architecture/holedeck-waffle-slabconstruction-system-saves-20-floor.html • Fundamentals of Building Construction Edward Allen – Joseph Iano.