What To Sanitize

advertisement

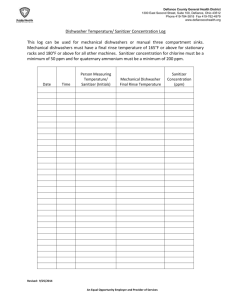

1 Our Mission Our mission is to provide the highest quality of food with great service in a clean, safe and comfortable environment for every customer. Each NFP Volunteer has important responsibilities that will ensure the safety of our customers and is responsible for following the guidelines that govern food safety and sanitation standards. 2 Sanitation Regulations No Eating or Drinking in any Food Prep Areas. Breaks can be taken in the Lions Den. Clean Hands and Gloves are Critical – wash hands, change gloves frequently. No bare hand contact. Maintain Proper Cooked Food & Storage Temperature Logs. Proper set-up of the 3 Compartment Sink & Sanitizer Buckets. Maintaining a clean and sanitized Food Prep Area. Covered cuts on hands with a bandage and disposable glove. 3 Personal Checklist Before you start work, make sure you have: Clean uniform. Washed your hands. Disposable gloves. While working, make sure you: Wash hands and change gloves when dirty or after touching anything other than food or utensils. Do not eat or drink at work stations. Drink from a cup with a straw and lid. Place cups away from food prep areas below all supplies and product. No soda cans or bottles with screw caps. Keep your work area clean and organized. 4 Requirements for Safe Food Handling Person-in-Charge (Stand Leads) Must monitor sanitation throughout the entire event. Safe Food Handling Kit – Thermometers, alcohol swabs, Quaternary Test Strips. Single Use-Disposable Gloves - for handling and preparing food. Temperature Log Sheets - to insure that all food - hot or cold is always kept at the proper temperature. 3 Compartment Sink for utensil and equipment washing - w/antibacterial detergent/degreaser & sanitizer. Sanitizer Buckets w/Food Service Towels 5 Requirements for Safe Food Handling (cont’d) Hand washing Sink- w/disposable towels & soap. Garbage Containers - w/liners Mop Sink - for disposing of waste water, Only – NO GREASE! Broom, Mop & Mop Bucket - for sweeping and mopping of floors. Refrigeration/Freezers - for Cold Food Storage Crescors or Hot Food Storage Units - Warmers, Heated Display Units. Storage Racks/shelves - For keeping all food related products off the floors 6 Keep it Safe Meat Storage –Meat must be stored below ready-to–eat foods in the refrigerators. All products should be date marked at the end of the event. Cross Contamination – Prep surfaces, utensils, pans, etc. must be washed and sanitized before handling. Hands need to be washed and gloves need to be changed often. Dry Storage 6” off the Floor – All food product and food related items must be stored on the shelving units and off the floor at all times. Do not place boxes, containers or crates on food prep surfaces. Ice Scoops/Ice Buckets – Ice is a food and needs to be treated as such. Ice scoop handles should never be touching ice being served. Store with the handle up – out of the ice. Place Ice scoops from the Ice machines on the hooks on the sides – never place in the ice inside the machine. Ice buckets are stored on the shelving units, not on the tops of the ice machines (dirty). Not on floor. Keep ALL areas clean – All areas - counters, prep surfaces, equipment, floors, under counters, etc. must be kept clean, sanitized and free of debris during the event for show quality and safety and after the event to prevent infestation and vermin. 7 Proper Hand Washing Hand Washing Sinks ONLY! 1.Wet your hands with hot water, as hot as can be tolerated 2. Use plenty of soap, vigorously rubbing your hands together. 3. Scrub your hands, wrists and forearms for at least 20 seconds. Be sure to clean under your finger nails, too. (Ask someone to time you for the 20 seconds to demonstrate how long 20 seconds is.) 4.Rinse for at least 5 seconds, or until all soap has been removed, whichever is longer. 5. Dry your hands using clean, unused disposable paper towels. 6. Put on single use disposable gloves to prepare food. 8 Three Compartment Sink Begin by wiping the three sinks. You will see throughout your work areas chemical dispensing systems. These are set up to provide the right amount of chemicals and water dilution. Only press the buttons once for the washing and sanitizing sinks. It is important that we use the right concentrations; too much or too little or the wrong water temperature and we will not have sanitized work surfaces. Run cool water to mix with chemicals to the fill lines provided on each sink. Tear off about one inch of test strip. Place the strip into the sanitizer solution for 10 seconds, holding it steady. Compare the resulting color of the strip to the color chart on test strip container to see if the solution is correct. It must be at 200 ppm. Sanitizer Buckets 9 Rinse and wipe each sanitizer bucket before filling. You will fill all sanitizer buckets from the sanitizer sink provided the sanitizer water has been tested and the levels are correct. Simply scoop the buckets from the sink and place one cleaning cloth in each. Portable locations will need to fill sanitizer buckets from nearby locations. Please work with your neighbors! When bucket are filled, the sanitizer sink should be emptied and filled again for dishes, repeating the previous procedure. You will need to check the concentration of the sanitizer solution at least every two hours. It should be changed when: Solution strength falls below the appropriate strength Solution becomes soiled or cloudy 10 Using Sanitizer! What To Sanitize: Sanitize food contact surfaces. These include counters, equipment, worktables, and any surface that comes in contact with food or foodservice items. Allow to air dry. What You Need: Buckets with sanitizer. These should be Red or labeled “Sanitizer”. Use test strips to make sure it is at the right strength: Quat at 200 ppm with cool water Provide one clean towel in each sanitizer bucket. Change the sanitizer solution often. 11 Importance of the Thermometer Temperature is a critical measurement for ensuring the safety and quality of many food products. Thermometers should be calibrated whenever they are dropped, before first used, and when going from one temperature extreme to another. Clean and sanitize the thermometer before using and after each temperature by wiping thoroughly with an alcohol swab available in your stands crash kit, after each temperature check. 12 Calibrating a Thermometer Create an ice-bath by filling a container with ice and water. Place the probe of the thermometer into the ice-bath with the dimple on the stem below the water level. Keep the thermometer in the ice bath until the dial comes to a stop. If the thermometer does not register 32F, adjust the dial using the nut just below the dial and then recheck using the ice-bath. Continue this process until the thermometer reads 32F. You should check your thermometer throughout your shift and recalibrate it as necessary. 13 Food Temperature and Quality Hot Food All Potentially Hazardous Foods are held at 40 F or below, cooked to 165 F or above, and recorded on TPHC chart, Time, Temp, and Discard Time. Please assemble in small batches to ensure proper temperature. All Potentially Hazardous Foods are held at or above 145 F for no more than 1 hours to ensure the highest food quality. Cold Food All Potentially Hazardous cold items are prepared and stored at or under 40 F. Once items are assembled (pre portioned salads and sauces), they must be recorded on TPHC chart, Time, Temp, and Discard Time. All cold items are discarded within 2 hours of assembly. 14 Taking Temperature Clean and sanitize your thermometer using alcohol swab found in your location’s crash kit. You must sanitize your thermometer before and after each use including before checking the temperature of the next item. Insert the probe into thickest part of the food and wait for dial to stop. Take the temperature in more than one area of food, if possible. Adjust the thermostat of the hot holding unit if necessary. If the hot holding unit does not maintain proper temperature, use a different unit and notify your zone manager immediately. Document all temperatures using the temperature logs provided by your manager. 15 Danger Zone 16 Which of the following steps is NOT part of the proper procedure for washing hands? • • • • A. Rinse hands with warm water for 5 seconds. B. Apply bleach and rub hands together for 20 seconds. C. Apply hand soap and scrub hands, wrists and forearms for 20 seconds. D. Use a single-use towel to dry hands. C What is the proper level of quaternary sanitizer for the three compartment sink and sanitizer buckets? • • • • A. 400 ppm. B. 200 ppm. C. 500 ppm. D. Levy uses bleach not quaternary sanitizer. B When taking the temperature of food: • • • • A. Clean the thermometer with a dry cloth. B. Place the thermometer probe on the surface of the food. C. Use a thermometer capable of reaching from 50°F to 550°F. D. Insert the thermometer probe into the thickest part of the food. Store sanitizing cloths: • • • • A. In sanitizing solution. B. On your apron string. C. Hanging in the kitchen. D. On the counter near work area. A What is the proper way to store ice scoops? • • • • A. Handle up and out of the ice or on a sanitized surface. B. In the ice bin covered in ice. C. Sanitizer bucket. D. On top of the pop machine. A D When eating at your work station you should: – – – – 17 A. Wash your hands first. B. Keep your food and drink covered at all times. C. Use disposable utensils. D. I am not allowed to eat at my workstation. To help prevent cross-contamination, you should: – – – D A. Cover all food items in the refrigerator, freezer, and storage. B. Wash your hands and put on a fresh pair of sanitation gloves before beginning a new task. C. Use a clean, sanitized cloth to clean the work area throughout your work shift. B Using the Time v Temperature procedure requires us to: – – – – A. Time how long it takes to cook an item B. Take temperatures at different time of the shift C. Nothing D. Discard all foods at a scheduled interval to ensure no food is held longer than 2 hours from production time D The temperature Danger Zone is: – – – – A. 70°F - 75°F B. 50°F - 500°F. C. 41°F - 140°F D. 41°F - 70°F. C A properly calibrated thermometer should read : – – – – A. 41°F B. 140°F C. 32°F D. 0°F C