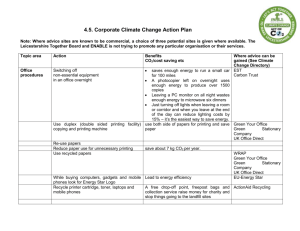

BV Dairy: LCAG results

advertisement

Low Carbon Action Group results 366.4 Building 2100.14 The nature of our business means a large amount of energy needs to be used, but we are looking to compensate that with the renewable energy production from the AD Plant. Due to a future rebuild there will not be any major investments made to improve current buildings Transport Our baseline year for measuring our carbon footprint is 2010. This covered the following scope: Electricity, Heating Oil, Company Transport In the baseline year the result of our Carbon Footprint assessment was 2466.54t CO2 /£m turnover Carbon Assessment Results Business Strategy Energy Efficiency IT Transport Marketing Overall Rating 1. Build a carbon management system, to identify carbon reduction targets 2. Consider using sub-metering to understand the energy usage across each segment of the business. This will help you understand which areas use the most energy, so you can target energy reductions more appropriately. 3. Look at improving communication to the staff at all levels relating to carbon management, and getting them more involved in generating ideas. 4. Look at ways of reducing draft and heat loss through the windows e.g. through using window insulation films. Held a ‘Green Day’ on 22nd March. A week earlier taster posters went up in the work place, then on Friday 18th March we issued our spring staff newsletter and then finally on 22nd March our green day. Followed up by talking to individuals and groups about their ideas. The bulk of the workforce contributed and quite a few ideas overlapped but we do have some serious contenders to follow up on which I am about to do. We also promised rewards for staff who came up with good ideas. High efficiency travelling belt oven which recirculates used heat back into the oven. There is minimal heat loss from this oven. The baking time is cut by approximately 40 % plus minimal heat gain to the bakery. It is estimated that fuel costs will be reduced by approximately 50% by using this oven with the subsequent saving in C02 emissions. T5 sized florescent tubes fitted, giving a 30% saving over T8 sized tubes. Install light sensors in low occupancy rooms such as toilets and changing areas. By using Good Manufacturing Processes, in recent months Fudges have reduced their ‘out of spec’ product waste by around 40%. This has resulted in higher yields per batch with subsequent reduced need to produce extra batches to cover manufacturing losses. Speed limiters added to company vehicles, to promote the reduction of fuel use. Monitoring our electricity usage in the office to determine where best to reduce consumption. Holding an environmental awareness week which will include carbon reduction and energy efficiency. Implementing ISO 14001 to continually review the carbon management and commit to a target of reduction. Upgrade lighting to a more energy efficient version throughout the facility and are currently in the process of applying for a grant towards this from IYRE & Business link. Upgrade our computer system to a thin client system to save energy. Compressed air leak check by Implemented a cross site monitoring system. Lighting specialists endorsed the T8 to T5 tube conversion, for offices. Tool box talks with employees to increase their understanding of how we as a company waste Energy and get some buy in on Energy saving activities i,e if its not in use turn it off. Installing control devices for equipment that only needs to use energy at specific points during our processes, (rather than one on and off switch for our entire process) Installing speed doors instead of shutter doors where constant access and egress is required of large goods. (Aids reducing energy used heating) What have we done, where are we going next? Compressed air leak check 16.5t CO2, £2262 IRYE grant applied for £10000 and looking to add to it and replace the entire system 33%more efficient saving 45t CO2 Trucks use an exhaust gas recirculation system reducing emissions by 2.6kg less CO2 per litre of fuel with an overall saving of 25t CO2/year per vehicle Recycled packaging and 50% landfill waste reduction achieved Emulate Craftwood's green day plus ESH newsletter Lighting survey to be carried out and switch-off monitoring Staff communication via the Company conference