Chapter 1

advertisement

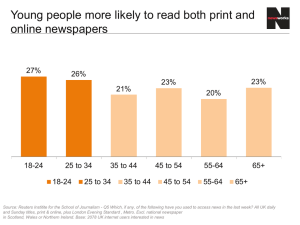

1 Operations and Productivity PowerPoint presentation to accompany Heizer and Render Operations Management, 10e Principles of Operations Management, 8e PowerPoint slides by Jeff Heyl 1 Outline What Is Operations Management? Organizational Design Decisions in OM Significant Events in OM Operations in the Service Sector New Challenges in OM The Productivity Challenge Productivity Example Ethics and Social Responsibility 2 What Is Operations Management? Production is the creation of goods and services Operations management (OM) is the set of activities that create value in the form of goods and services by transforming inputs into outputs 3 Organizational Charts Commercial Bank Operations Finance Marketing Teller Scheduling Check Clearing Collection Transaction processing Facilities design/layout Vault operations Maintenance Security Investments Security Real estate Loans Commercial Industrial Financial Personal Mortgage Accounting Auditing Trust Department Figure 1.1(A) 4 Organizational Charts Airline Operations Ground support equipment Maintenance Ground Operations Facility maintenance Catering Flight Operations Crew scheduling Flying Communications Dispatching Management science Finance/ accounting Accounting Payables Receivables General Ledger Finance Cash control International exchange Marketing Traffic administration Reservations Schedules Tariffs (pricing) Sales Advertising Figure 1.1(B) 5 Organizational Charts Manufacturing Operations Facilities Construction; maintenance Production and inventory control Scheduling; materials control Quality assurance and control Supply-chain management Manufacturing Tooling; fabrication; assembly Design Product development and design Detailed product specifications Industrial engineering Efficient use of machines, space, and personnel Finance/ accounting Disbursements/ credits Receivables Payables General ledger Funds Management Money market International exchange Capital requirements Stock issue Bond issue and recall Marketing Sales promotion Advertising Sales Market research Process analysis Development and installation of production tools and equipment Figure 1.1(C) 6 The Critical Decisions(1 of 2) 1. Design of goods and services 2. Managing quality 3. Process and capacity design 4. Location strategy 5. Layout strategy Table 1.2 (cont.) 7 The Critical Decisions(2 of 2) 6. Human resources and job design 7. Supply-chain management 8. Inventory, MRP, and JIT 9. Intermediate & short–term scheduling 10. Maintenance 8 Significant Events in OM Figure 1.3 9 How Important is Manufacturing? In 1978 the United States produced 22% of the worlds manufactured goods. What percent does the United States produce today? 21% The US is still the largest manufacturer in the world. Although China is growing quickly. 10 How Important is Manufacturing 11 How Important is Manufacturing 12 How Important is Manufacturing 13 Goods versus Services goods McDonald’s (facilitating goods) Pencil Manufacturer • tangible • storable* • easy quality assessment • centralized production • long lead times • capital intensive • low customer contact • production separate from consumption services Psychologist • intangible • perishable* • difficult quality assessment • dispersed production • short lead times • labor intensity • high customer contact • production concurrent with consumption 14 Goods and Services Automobile Computer Installed carpeting Fast-food meal Restaurant meal/auto repair Hospital care Advertising agency/ investment management Consulting service/ teaching Counseling 100% 75 50 25 0 25 50 75 100% | | | | | | | | | Percent of Product that is a Good Percent of Product that is a Service 15 New Challenges in OM From To Local or national focus Global focus Batch shipments Just-in-time Low bid purchasing Supply-chain partnering Lengthy product development Rapid product development, alliances Standard products Mass customization Job specialization Empowered employees, teams 16 Productivity Challenge Productivity is the ratio of outputs (goods and services) divided by the inputs (resources such as labor and capital) The objective is to improve productivity! Important Note! Production is a measure of output only and not a measure of efficiency 17 The Economic System Inputs Transformation Outputs Labor, capital, management The U.S. economic system transforms inputs to outputs at about an annual 2.5% increase in productivity per year. Goods and services Feedback loop Figure 1.6 18 Productivity Units produced Productivity = Input used Measure of process improvement Represents output relative to input Only through productivity increases can our standard of living improve 19 Productivity Calculations Labor Productivity Productivity = = Units produced Labor-hours used 1,000 250 = 4 units/labor-hour One resource input single-factor productivity 20 Multi-Factor Productivity Output Productivity = Labor + Material + Energy + Capital + Miscellaneous Also known as total factor productivity Output and inputs are often expressed in dollars Multiple resource inputs multi-factor productivity 21 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day 8 titles/day Overhead = $400/day 8 titles/day Old labor = productivity 32 labor-hrs 22 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day 8 titles/day Overhead = $400/day 8 titles/day Old labor = productivity 32 labor-hrs = .25 titles/labor-hr 23 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day New System: 14 titles/day 8 titles/day Overhead = $400/day Overhead = $800/day 8 titles/day Old labor = productivity 32 labor-hrs = .25 titles/labor-hr 14 titles/day New labor = productivity 32 labor-hrs 24 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day New System: 14 titles/day 8 titles/day Overhead = $400/day Overhead = $800/day 8 titles/day Old labor = productivity 32 labor-hrs = .25 titles/labor-hr 14 titles/day New labor = = .4375 titles/labor-hr productivity 32 labor-hrs 25 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day New System: 14 titles/day 8 titles/day Overhead = $400/day Overhead = $800/day 8 titles/day Old multifactor = productivity $640 + 400 26 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day New System: 14 titles/day 8 titles/day Overhead = $400/day Overhead = $800/day 8 titles/day Old multifactor = = .0077 titles/dollar productivity $640 + 400 27 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day New System: 14 titles/day 8 titles/day Overhead = $400/day Overhead = $800/day 8 titles/day Old multifactor = = .0077 titles/dollar productivity $640 + 400 14 titles/day New multifactor = productivity $640 + 800 28 Collins Title Productivity Old System: Staff of 4 works 8 hrs/day Payroll cost = $640/day New System: 14 titles/day 8 titles/day Overhead = $400/day Overhead = $800/day 8 titles/day Old multifactor = = .0077 titles/dollar productivity $640 + 400 14 titles/day New multifactor = = .0097 titles/dollar productivity $640 + 800 29 Ethics and Social Responsibility Challenges facing operations managers: Developing and producing safe, quality products Maintaining a clean environment Providing a safe workplace Honoring stakeholder commitments 30 In-Class Problems from the Lecture Guide Practice Problems Problem 3: Joanna French is currently working a total of 12 hours per day to produce 240 dolls. She thinks that by changing the paint used for the facial features and fingernails that she can increase her rate to 360 dolls per day. Total material cost for each doll is approximately $3.50; she has to invest $20 in the necessary supplies (expendables) per day; energy costs are assumed to be only $4.00 per day; and she thinks she should be making $10 per hour for her time. Viewing this from a total (multifactor) productivity perspective, what is her productivity at present and with the new paint? 31 In-Class Problems from the Lecture Guide Practice Problems Problem 4: How would total (multifactor) productivity change if using the new paint raised Ms. French’s material costs by $0.50 per doll? 32