theory. materials l1 - Olchfa Comprehensive School

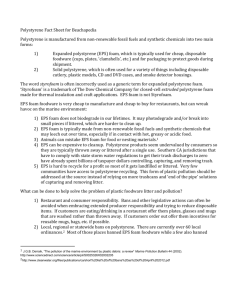

advertisement

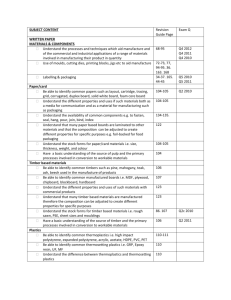

Technical aspects of designing and making Materials Aim of the lesson • To understand about different materials used by Graphic designers-what they are; how they are made; their properties and uses. Starter • Make a brainstorm or a list of as many words as you can think of that describe packaging. There are a wide variety of packaging materials for designers to choose from. Each material has its own characteristics. Some are rigid while others are flexible. Some are made from new materials, taking advantage of new technologies and processes. Others have been recycled and are therefore, usually, more sustainable. All of them come in a range of sizes. thickness, colour and finish. Paper Sizes Papers and boards come in different weights and sizes. Paper is measured in grams per metre squared (gsm), this refers to the weight per square metre. Anything over 200gsm is classed as board. Normal paper for exercise books and photocopiers is about 80gsm. Paper that is 160gsm is twice as heavy (Thicker). 500gsm is thick card. Paper and card • Paper and card are cheap to produce and are sustainable (they come from wood pulp – a sustainable source - and can be recycled). They can be cut and shaped with scissors or craft knives. They can be printed on easily but their main disadvantage is that they become weak when wet. • Tracing paper is used by pupils, students and designers. It allows the designer to copy an existing drawing / shape. Tracing paper can be useful when there is a need to produce several drawings that are based on the same outline. • Also, tracing paper makes it possible to place one design on top of another to produce a second layer. The original design can be seen under the second drawing. • Cartridge paper is used for general drawing. It is often good quality and generally 100 to 135g in thickness. • Cardboard is thicker than paper as it is made up of a number of layers, glue or laminated together. It makes an excellent printing surface for items like food cartons but isn’t very strong, particularly when wet. 125 - 300 gsm Paper and card • White board is a strong medium.It is bleached so it provides a good surface for printing. It is used for good quality packaging and book covers. 200 - 400 gsm • Duplex board is used for containers and can contain liquids as it may have a water-proof liner on the inside. It can have a waxy feel. This type of card is used by the food industry and consequently recycled card is not used in its manufacture. 230 - 420 gsm • Corrugated board is strong because it is composed of a top and bottom layer and in between there is a triangulated section. A triangular section is very strong compared to its weight. It is therefore ideal for storage boxes. 250+ gsm • Foil lined board is good quality cardboard with a aluminium foil lining. This type of container is ideal for ready made meals or take away meals. The foil retains the heat and helps keep the food warm. Plastics Thermoplastics Thermoplastics can be heated and shaped many times. Thermoplastic will soften when it is heated and can be shaped when hot. The plastic will harden when cooled, but can be reshaped because there are no links between the polymer chains. Thermoplastic sheet is ideal for line bending and vacuum forming in packaging. Some examples: Thermoplastics • Polythene: low density (LDPE): Tough, good resistance to chemicals, flexible and fairly soft. Used for packaging, especially bottles, toys, packaging film and carrier bags. • Polythene: high density (HDPE). Hard, stiff, able to be sterilised. Used for things like 'plastic' bottles, milk crates. • Acrylic : Stiff and hard but scratches easily. Durable but can be brittle. Used for things like signs, covers of storage boxes. • Polypropylene (PP): Lightweight and hard but can scratch easily, tough. Used for things like school chair seats, CD cases and containers. • High impact polystyrene (HIPS) : Light but strong plastic. Widely available in sheet form. Used for vacuum forming. • UPVC (polyvinyl chloride): Hard wearing. Used for soft drinks containers that are not pressurised. • Polyester: PET (Polyethylene terephthalate) : is the most common plastic. It is shatter proof, becoming very popular for drinks containers. It is shatter proof, light weight and 90% recyclable. Used for things like plastic bags and food and drink containers. Plastics Thermosetting plastics Thermosetting plastics can only be heated and shaped once. If re-heated they cannot soften as polymer chains are interlinked. Separate polymers are joined in order to form a huge polymer. The main thermosetting plastics are, melamine formaldehyde, polyester resin and urea formaldehyde Thermosetting plastics Some examples: • Epoxy resin: is known for having excellent adhesion, chemical and heat resistance and very good electrical insulating properties. Used as an adhesive and in surface coatings. • Polyester resin (PR): Stiff, hard, brittle unless laminated, good electrical insulator, Used for casting and encapsulation, bonding of other materials. • Urea formaldehyde (UF). Used for things like electrical fittings and adhesives. Foam board Foam board • Foam board is a very strong, lightweight, and easily cut material. • It consists of three layers — an inner layer of Polystyrene foam clad with outer facing of either a white clay coated paper or brown paper. • Foam board does not adhere well to some glues, such as superglue and certain types of paint, as it dissolves the foam. Best results are obtained from using spray mount. Styrofoam Styrofoam • The term Styrofoam is actually a trademark for thermal insulation made from expanded polystyrene. • Polystyrene is thermoplastic, which means it can melt at a high temperature and become a solid again upon cooling. • Styrofoam has strong insulating properties. This means it is good for keeping food warmer and fresher for longer than paper-based products. • Styrofoam is not biodegradable but can be recycled into other products. Corriflute Corriflute • Corriflute or corriboard is a type of corrugated produced from high-impact polypropylene resin material. • It is a light-weight tough material which can easily be cut with a craft knife. Manufacturers typically offer a wide variety of colours and thicknesses (commonly 4 mm). • It can be joined using hot melt glue and there are a range of colours available. Also, it is impact and heat resistant. • Corrugated plastic is usually made from polypropylene which is capable of being recycled. Corriflute Corrugated card Plenary • You have 10 minutes to answer the following questions: